Method for monitoring porefilling capability of copper electroplating solution

A technology of copper electroplating solution and electroplating solution, applied in the direction of electrolysis process, electrolysis components, material electrochemical variables, etc., to achieve the effect of improving productivity, promoting scientific research progress and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

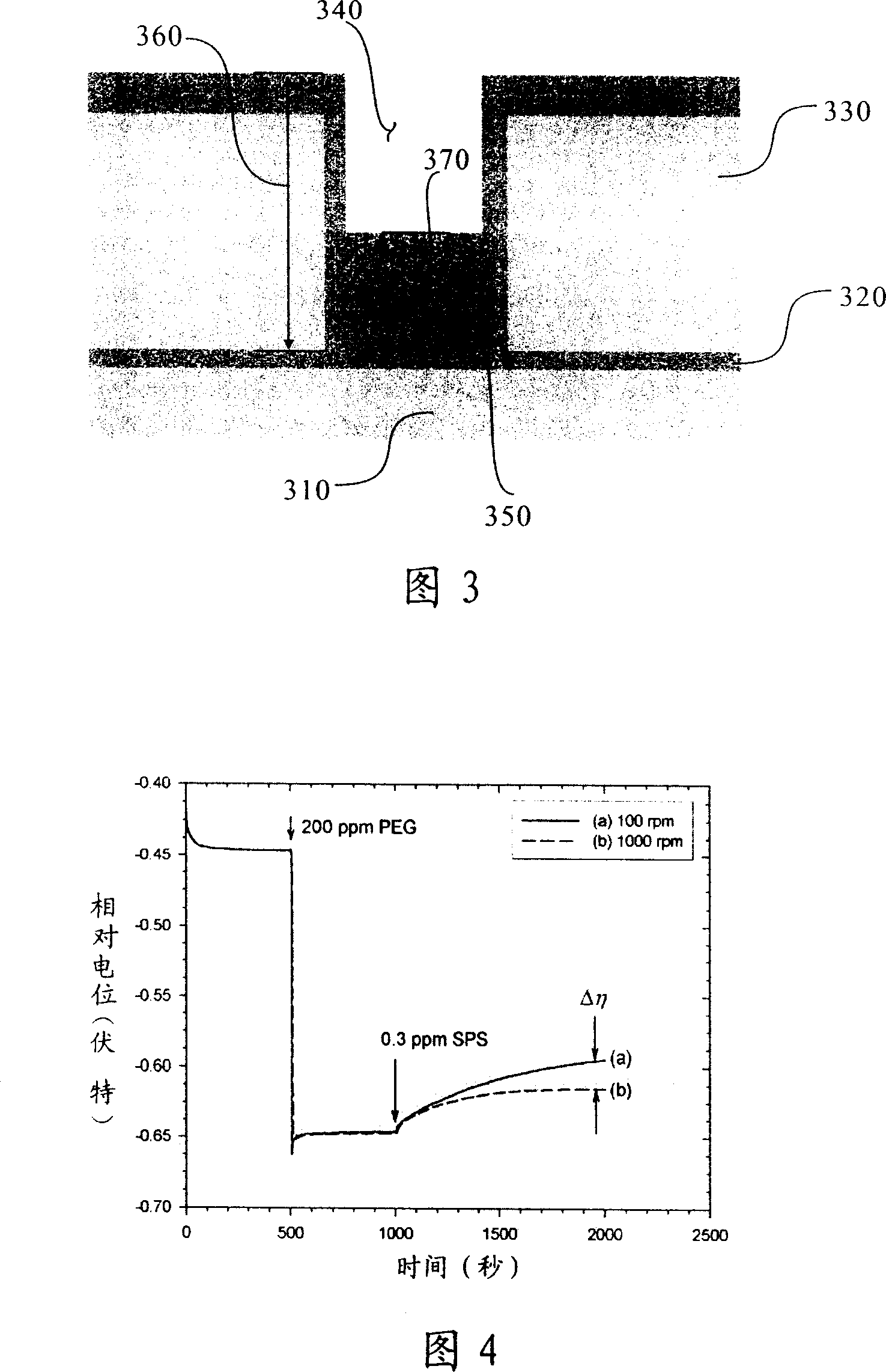

[0062] Please refer to Figure 4. Based on the blank electrolyte and 60ppm of chloride ions, when the constant current measurement is carried out to 500 seconds, 200ppm of inhibitor (PEG) is injected, and then 0.3ppm is injected at 1000 seconds. Accelerator (SPS) is used for constant current measurement, and its relative potential is measured at different electrode rotation speeds to observe the effect on hole filling ability without leveling agent. A potential difference (Δη) can be obtained from the measurement results at two rotational speeds, which is the potential difference obtained by subtracting the potential measured at 1000 rpm from the potential measured at 100 rpm as the hole filling ability index. If the potential difference is positive, it means that the formula has the ability to fill holes, otherwise, if the potential difference is negative, it means that the filling cannot be performed.

[0063] The results show that the electroplating formula shown in Figure ...

example 2

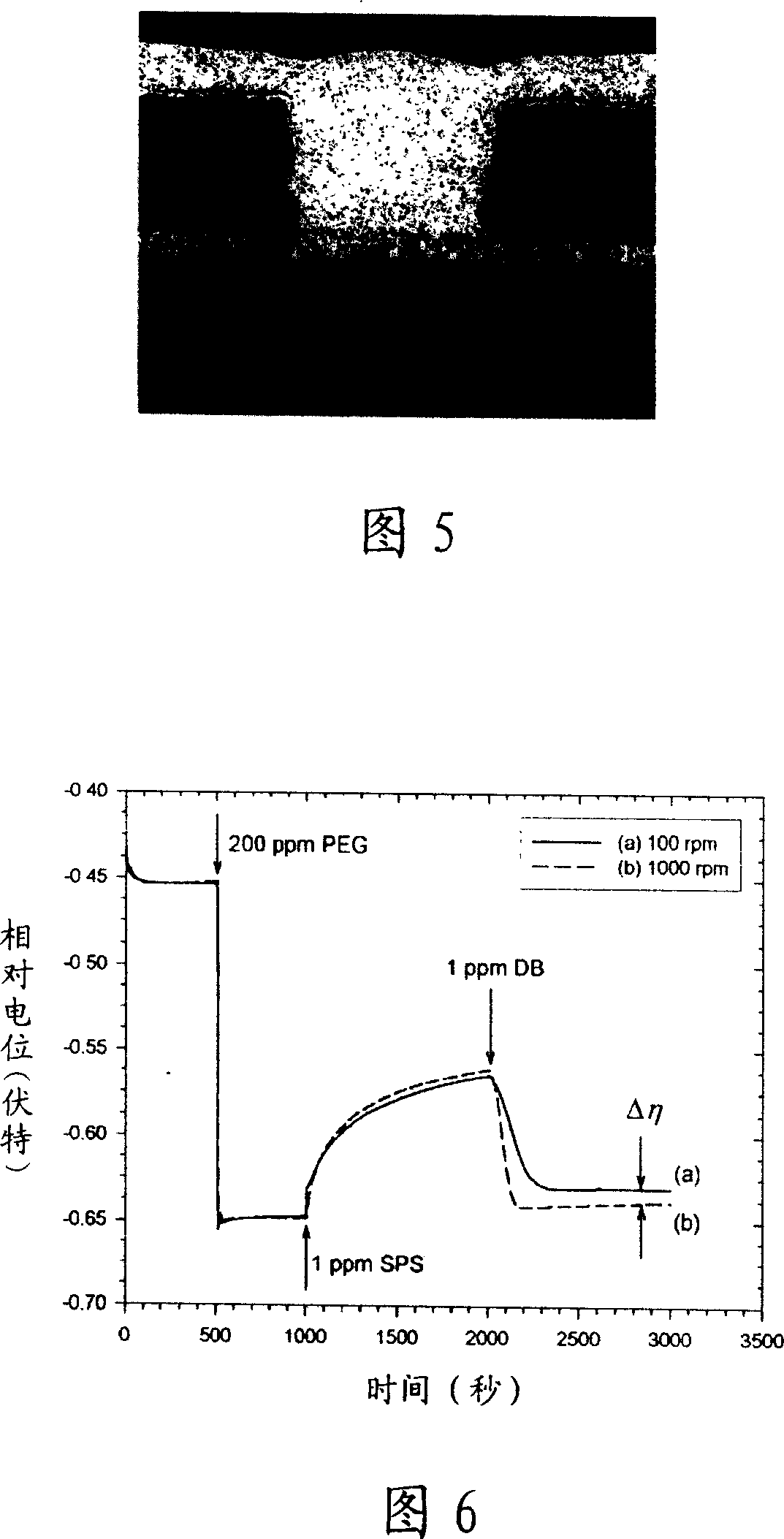

[0067] Please refer to Figure 6, when the SPS concentration in the formulation is increased from 0.3ppm to 1ppm, the predicted pore filling ability is shown. When 1ppm of SPS was injected into the basic plating solution containing 200ppm inhibitor (PEG) and 60ppm chloride ions, the relative potential measured at high electrode rotation speed (1000rpm) was low (dotted line b), while at low rotation number (1000rpm) The measured relative potential is higher (solid line a), and there is a negative potential difference between the two, so it can be known that this formula should not have the ability to fill holes. This result can be attributed to the excessive accelerated deposition of copper on the blind hole plate due to the excessively high SPS concentration. The interaction of ions with the accelerator SPS at a concentration of 0.3 ppm was destroyed. Therefore, uniform deposition of copper on the blind hole plate can also be seen in the cross-sectional view of the hole in Fig...

example 3

[0070] Please refer to Figure 9, where the DB is changed to JGB injected at 1ppm. The result shows that the relative potential (dotted line b) of the rotating electrode at a rotation speed of 1000 rpm is higher than that at a rotation speed of 100 rpm (solid line a). Compared with Figure 6, the potential difference is larger, so it is predicted that this formula should have good hole filling ability. Next, please refer to the cross-sectional view of the hole in Figure 10. The holes electroplated with this formula really show a good hole filling result, which is consistent with the constant current measurement result in Figure 9.

[0071] Continuing to refer to Figure 10, there is no semicircular protrusion on the top of the copper-deposited hole, but a flat surface. Compared with Figure 5, it should be attributed to the fact that JGB can improve the inhibitor (PEG )Effect. This result also shows that in electroplating, if there is no strong inhibitory effect produced by the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com