Vacuum storage tank type defecation discharge system for high speed train

A technology for high-speed trains and discharge systems, applied to railway car body components, sanitary equipment, transportation and packaging, etc., can solve the problems of high daily operating costs, huge one-time investment in ground treatment systems, etc., to achieve convenient cleaning and prevent The effect of software running away and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

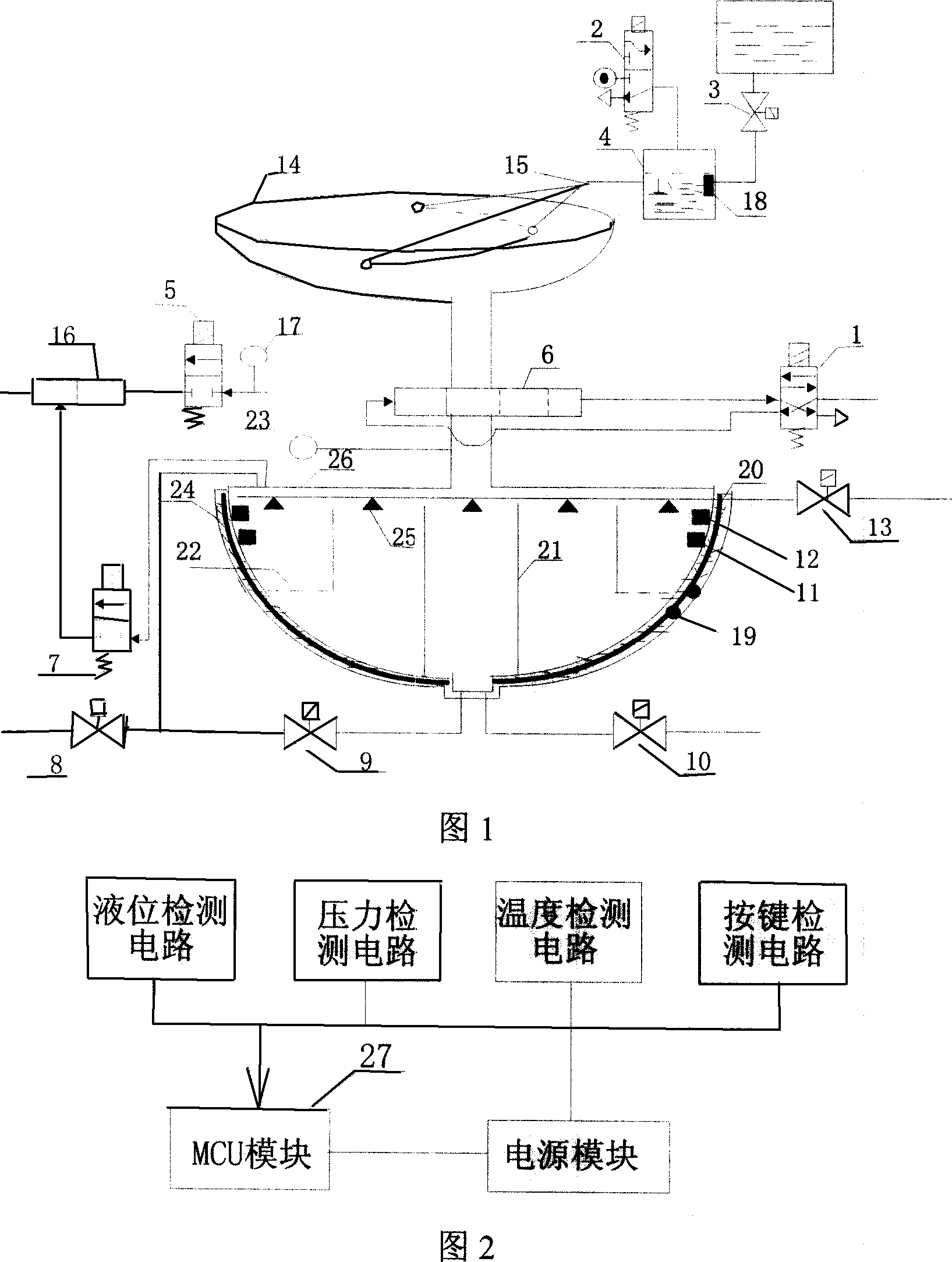

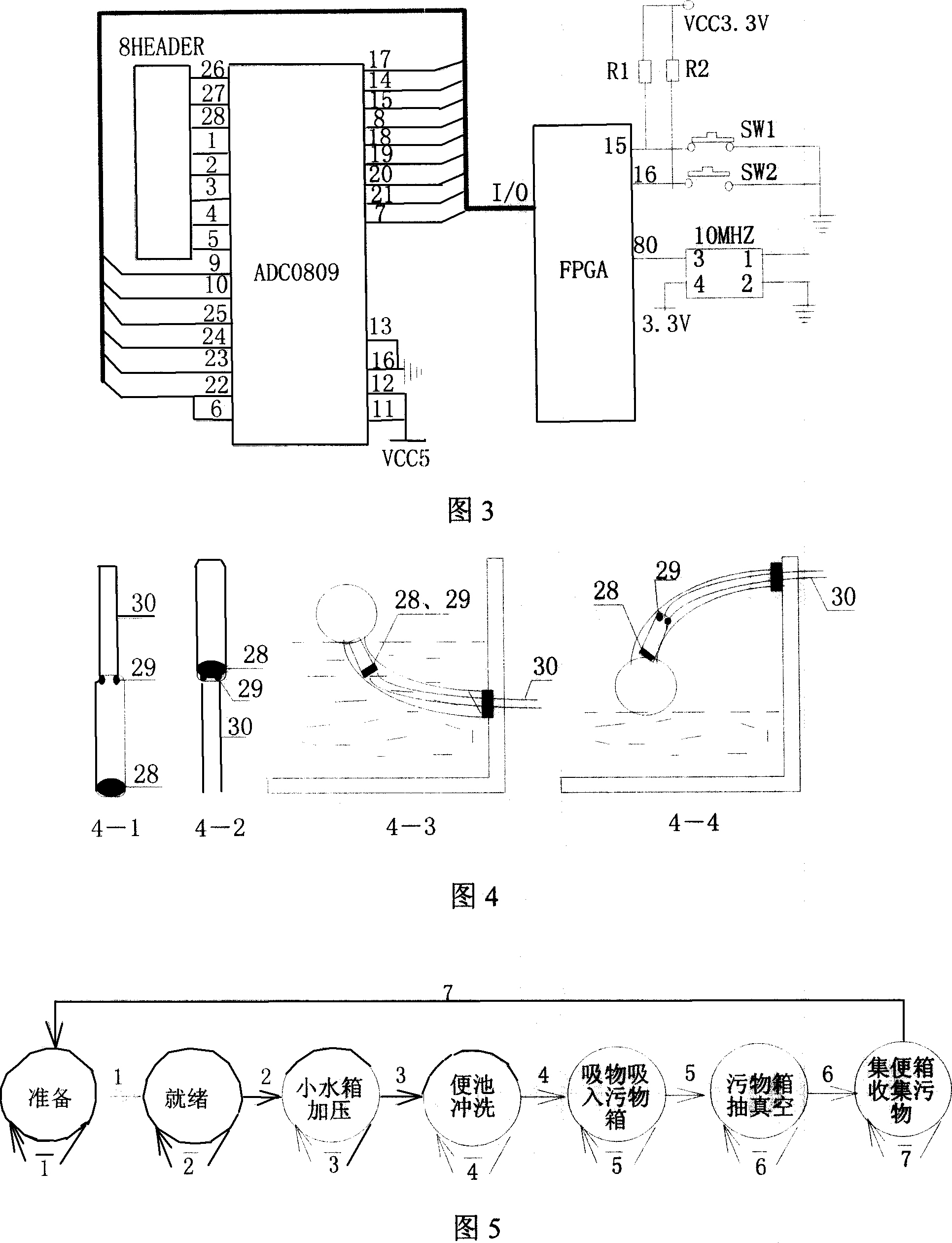

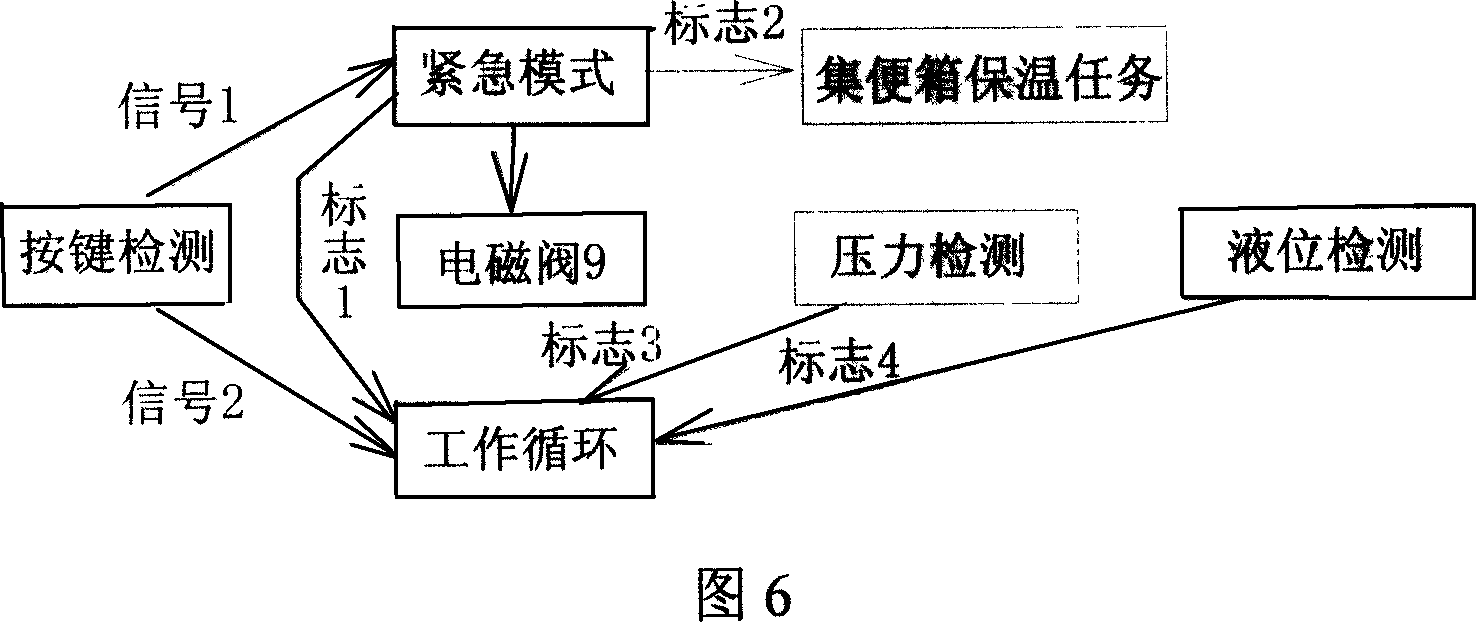

[0024]As shown in Figure 1, the excrement discharge system of the vacuum storage tank type high-speed train includes a toilet mechanical part assembly, a control executive valve assembly, a dirt box and a controller; the described toilet mechanical part assembly consists of a urinal 14, The flushing ring 15, the small water tank 4 and the vacuum generator 16 are composed; the flushing ring 15 composed of a plurality of water jets is set in the urinal 14, and the pneumatic jet vacuum generator 16 is respectively connected with the first two-position two-way solenoid valve 5, the second The outlet of the two-position two-way solenoid valve 7 is connected, and the inlet of the first two-position two-way solenoid valve 5 is connected to the air source high-pressure gas through the air source pressure sensor 17; the bottom of the small water tank 4 is connected with the flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com