Equipment for purifying metal in automobile exhaust catalyst

A technology for purifying equipment and automobile exhaust, which is used in gas treatment, chemical instruments and methods, and dispersed particle filtration. The effect of wasting and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

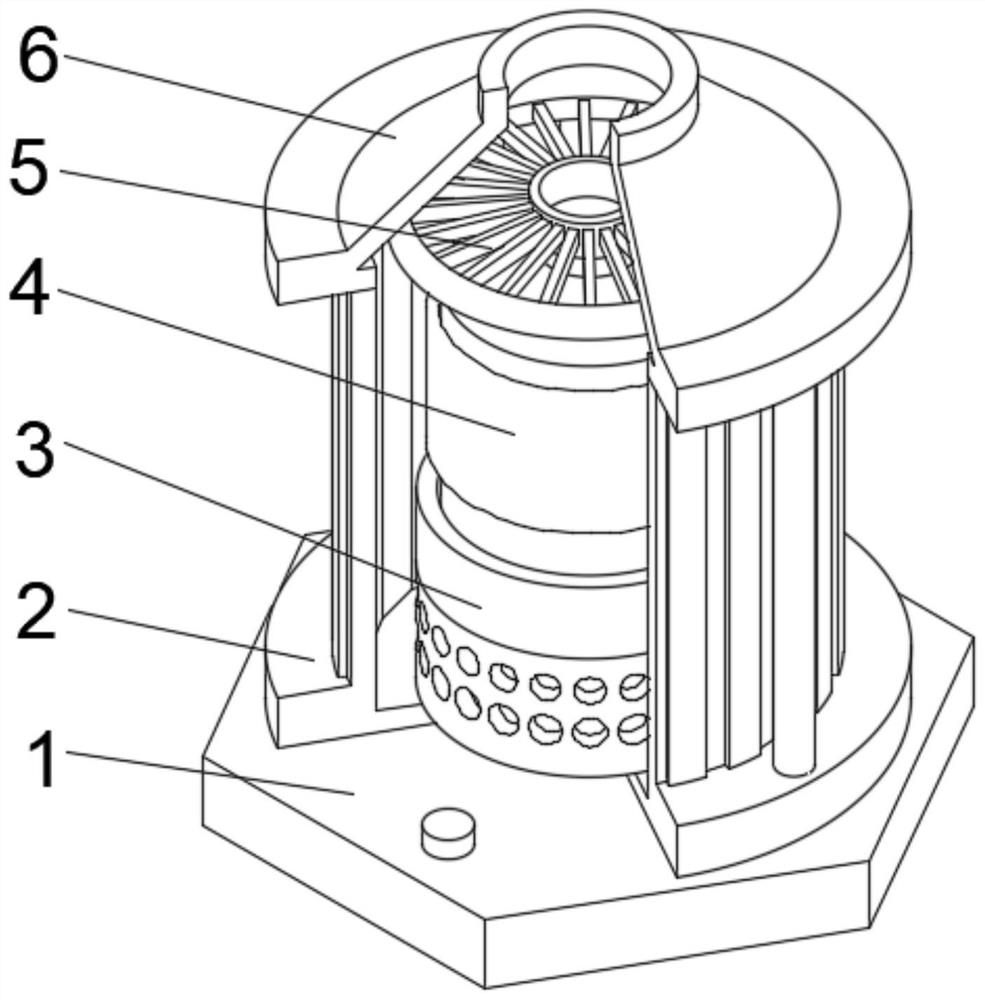

[0032] see Figure 1-2 , the present invention provides a technical solution: a metal purification device in an automobile exhaust catalyst, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a protective shell 2, and the top of the protective shell 2 is connected with an intake pipe 6, and the protection A filter discharge layer 3 is provided in the middle of the bottom of the inner cavity of the shell 2, and the top of the inner wall on both sides of the filter discharge layer 3 is fixedly connected with a purification device 4, and the top of the purification device 4 penetrates the filter discharge layer 3 and extends to the outside of the filter discharge layer 3 , a rotating ring 5 is provided at the middle of the top of the purification device 4 .

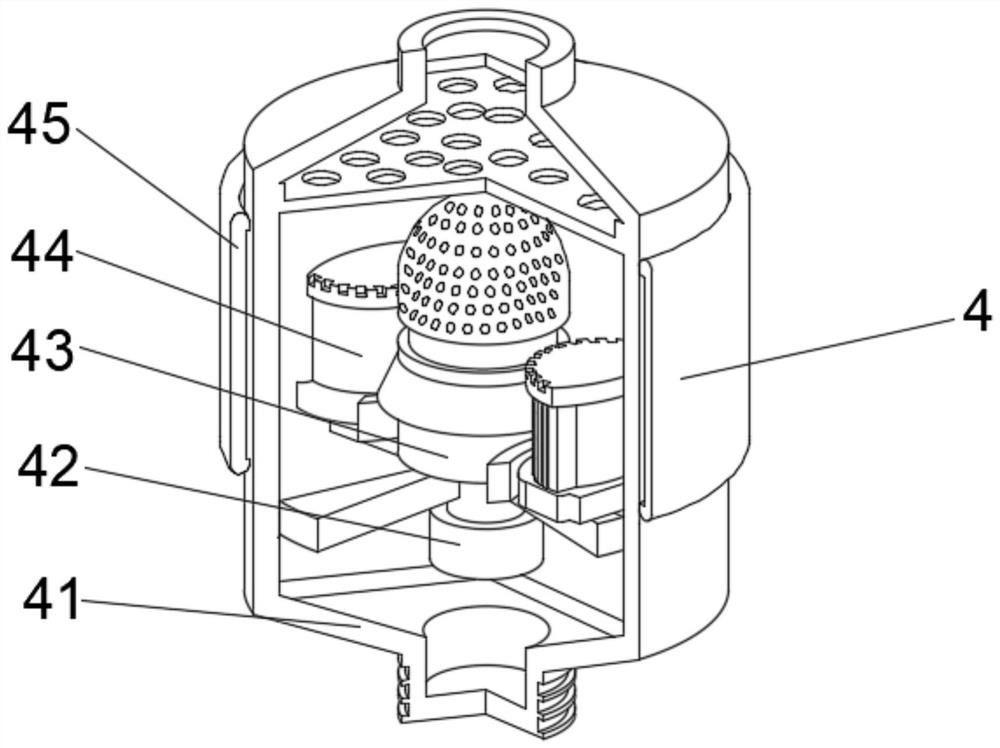

[0033] Wherein, the purification device 4 includes a purification main body 41, the middle part of the outer wall on both sides of the purification main body 41 is fixedly connected with a f...

Embodiment 2

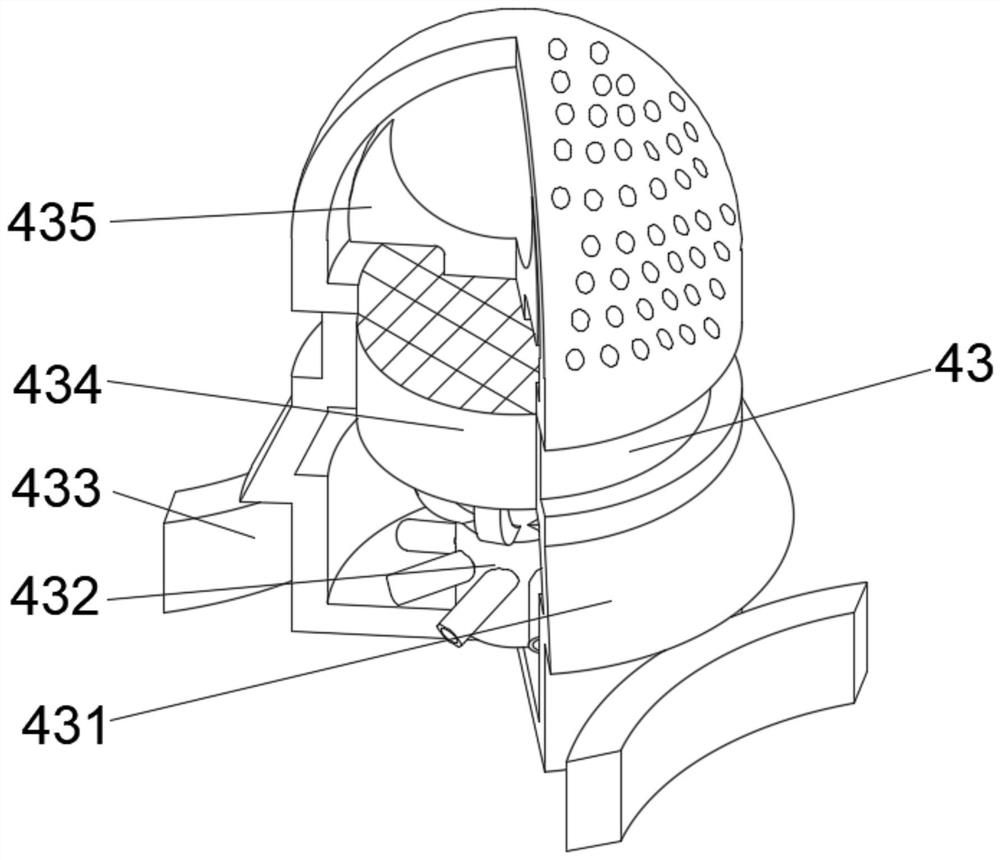

[0036] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the first component of the purification mechanism 43 includes a purifier 431, the bottom of the outer wall on both sides of the purifier 431 is fixedly connected with a positioning connecting plate 433, and the inner cavity of the purifier 431 A purification rack 432 is fixedly connected to the middle position of the bottom, a filter 434 is fixedly connected to the top of the purification rack 432 , and a suction member 435 is fixedly connected to the top of the purifier 431 .

[0037] Wherein, component one of the auxiliary mechanism 44 includes a bearing plate 441, the top of the bearing plate 441 is fixedly connected with a protective cover 442, and the middle position of the inner cavity bottom of the protective cover 442 is fixedly connected with an auxiliary body 444, and the inner cavity bottom of the protective cover 442 is located at the auxiliary body. Both sides...

Embodiment 3

[0040] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: Component 2 of the purification mechanism 43 includes a shell d1, and both sides of the inner cavity top of the shell d1 are fixedly connected with a purifier d2, and the purifier d2 A cooler d3 is provided at the bottom, a rotating collector d4 is fixedly connected to the middle position of the bottom of the cooler d3, and a seal d5 is fixedly connected to the bottom of the rotating collector d4.

[0041] Among them, the second component of the auxiliary mechanism 44 includes a thermal insulation shell t1, the bottom of the inner cavity of the thermal insulation shell t1 is fixedly connected with an installation liner t2, the bottom of the inner cavity of the installation liner t2 is provided with an extension body t3, and the top of the extension body t3 penetrates the installation liner The plate t2 extends to the outside of the installation liner t2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com