Exchanger with honeycomb structure

A technology of honeycomb structure and exchanger, which is applied in the direction of heat exchange equipment, heat exchanger type, indirect heat exchanger, etc. It can solve the problems of difficult placement of testing instruments, long production cycle, and large waste of materials, so as to save internal assembly, Excellent mechanical properties and great operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

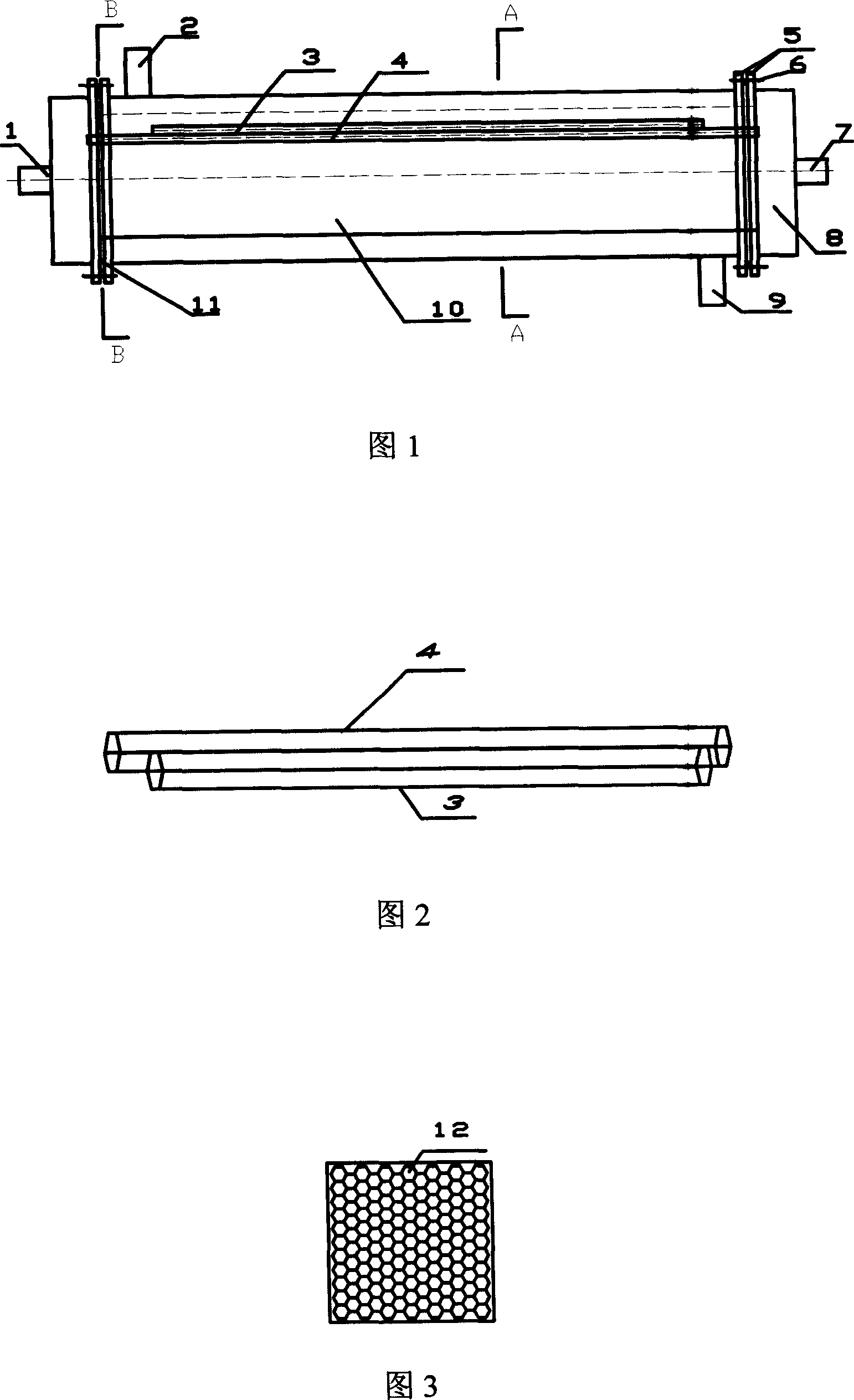

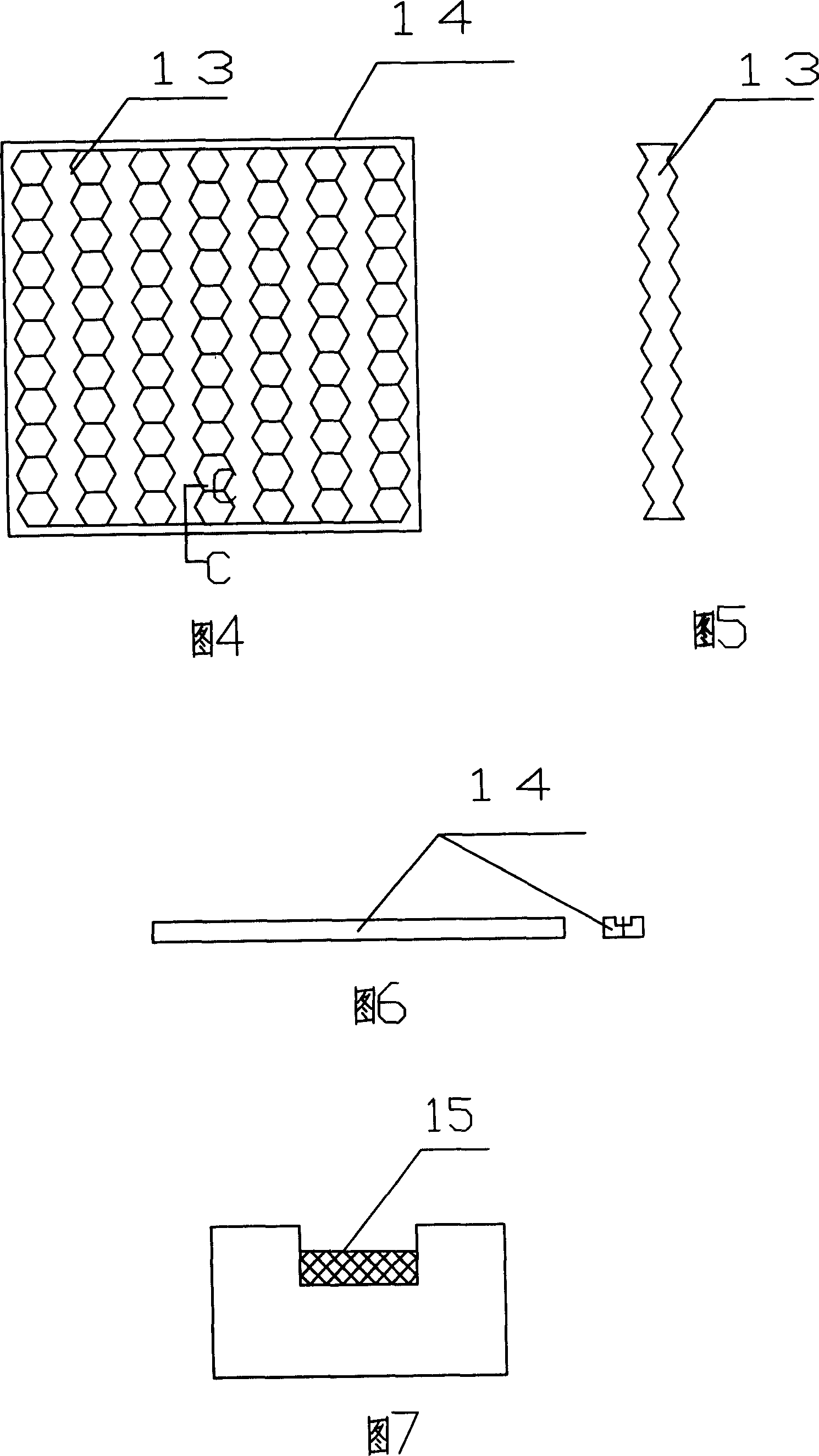

[0029] As shown in Figure 1, a kind of exchanger with honeycomb structure comprises casing 10 and tube bundle, and casing 10 is provided with fluid inlet 2 and fluid outlet 9, and casing 10 two ends are respectively provided with tube box 8, and tube box 8 is provided with a tube bundle fluid inlet 7 and an outlet 1, and the housing 10 has a regular hexagonal cross-sectional shape. The tube bundle consists of a plurality of short honeycomb tube bundles 3 and long honeycomb tube bundles 4 to form a honeycomb tube bundle core 12, and the gap between the outer edge of the honeycomb tube bundle core 12 and the shell 10 is less than 3mm. Both ends of the long honeycomb tube bundle 4 communicate with the inlet 7 and the outlet 1 in the tube box 8 respectively.

[0030] As shown in Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com