Photosensitive monomer, liquid crystal material, liquid crystal panel and photoelectric equipment and manufacture method thereof

A technology of photosensitive monomer and liquid crystal material, applied in liquid crystal materials, photosensitive materials for opto-mechanical equipment, chemical instruments and methods, etc., can solve problems such as image sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

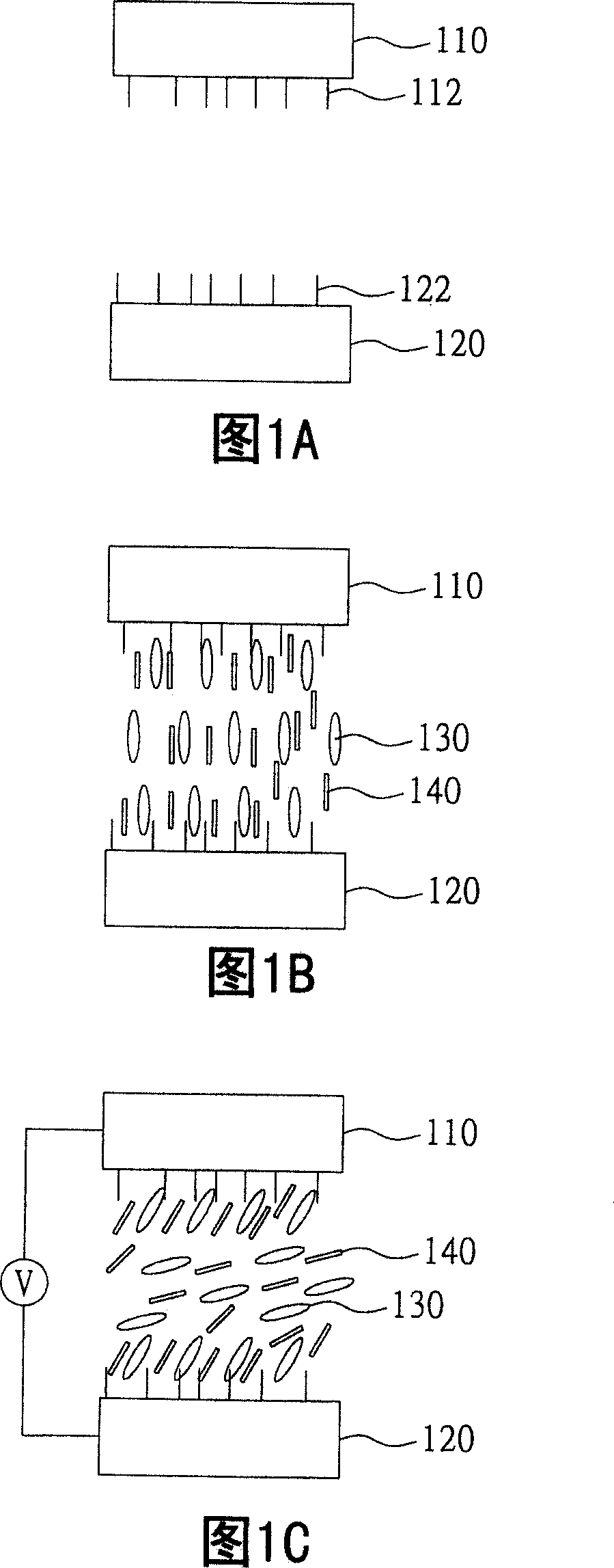

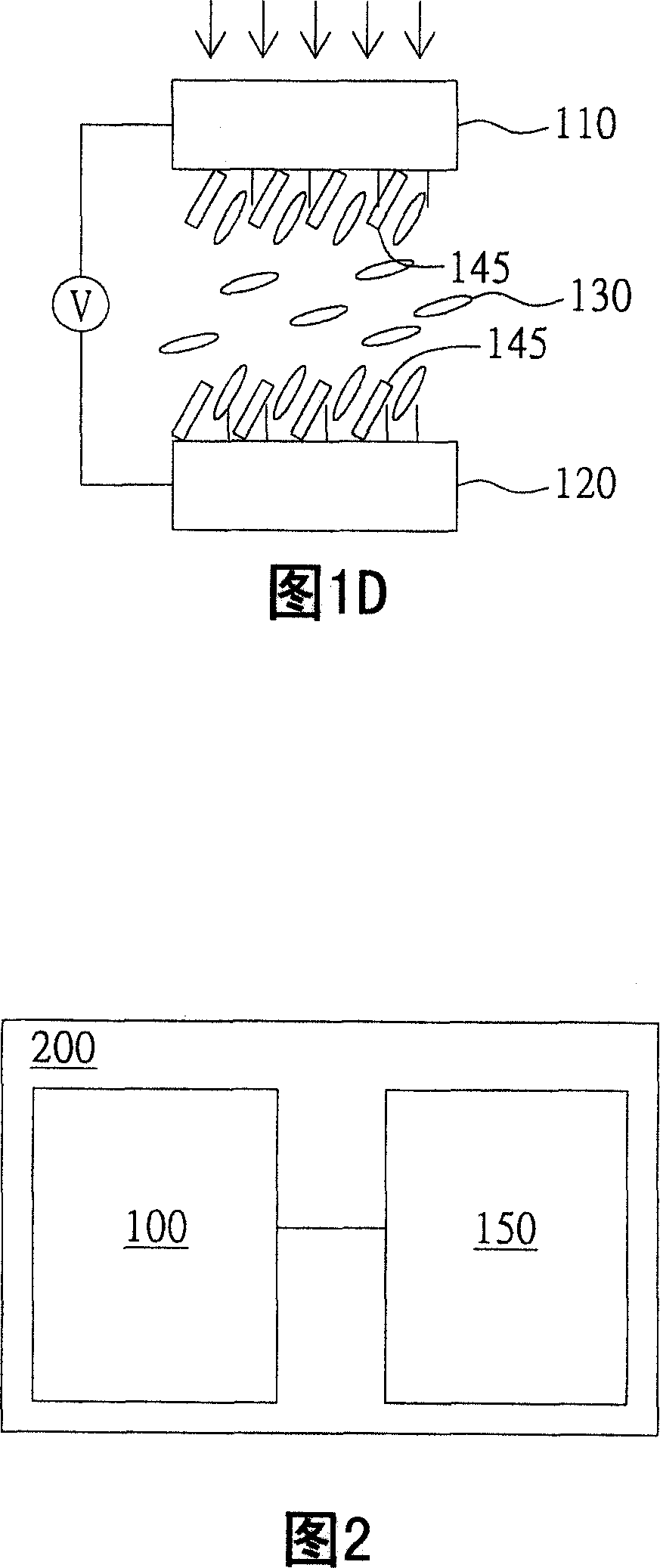

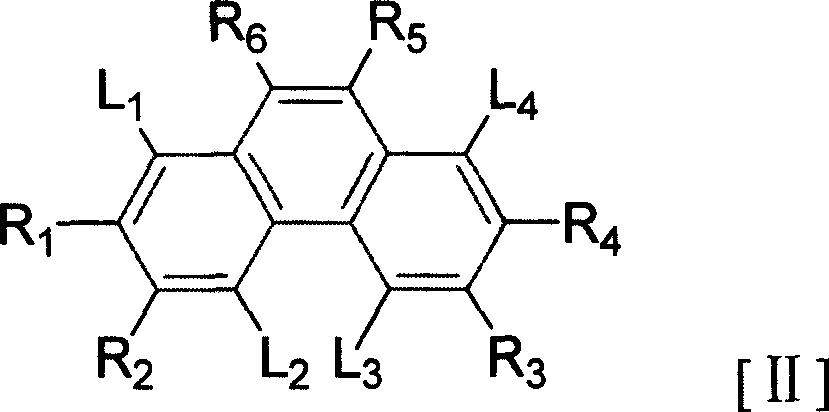

[0037] The present invention mainly proposes a photosensitive monomer, which can shorten the polymerization time and improve the problem of image sticking when applied to the manufacturing method of liquid crystal panels and optoelectronic devices. The general chemical formulas, preferred embodiments and synthesis methods of the photosensitive monomers are described below, as well as the methods of applying these photosensitive monomers to the fabrication of optoelectronic devices and liquid crystal panels.

[0038] photosensitive monomer

[0039] The present invention mainly proposes a photosensitive monomer, which has at least two polymerizable groups in the monomer, so when the photosensitive monomer receives light stimulation to carry out polymerization reaction, the polymerization reaction rate is relatively fast, reaching the required degree of complete polymerization. It also takes less time. The photosensitive monomer proposed by the present invention comprises at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com