Liquid dispensing method and system with headspace gas removal

A gas and liquid technology, applied in the field of storage and distribution systems, can solve the problem of difficult control of the gas volume in empty detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

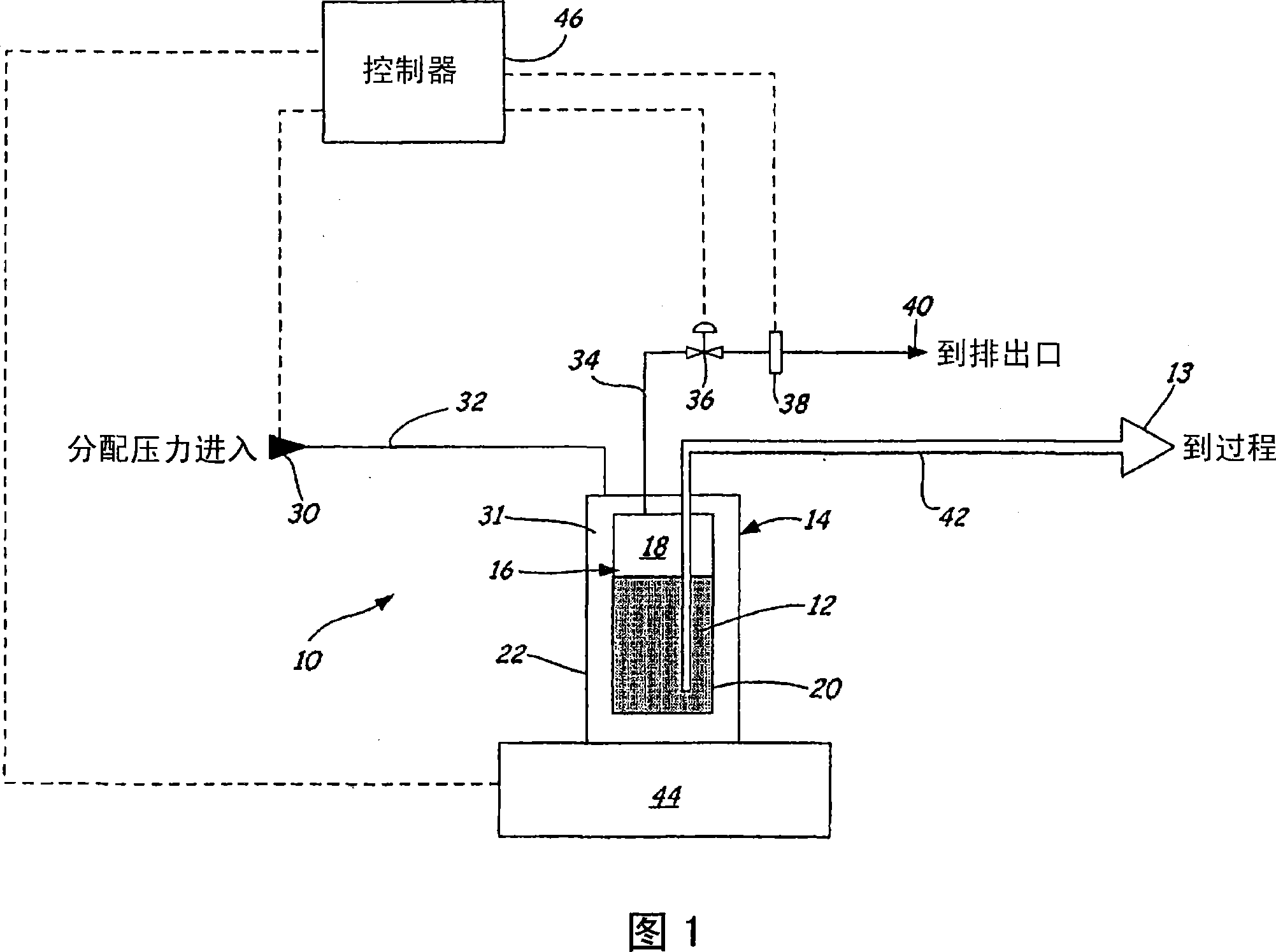

[0012] 1 is a schematic diagram of a system 10 for dispensing a liquid 12 from a container 14 including a headspace 16 filled with a headspace gas 18 to a manufacturing process 13 in accordance with a preferred embodiment of the present invention. Container 16 includes a flexible inner container 20 and a rigid outer container 22 . System 10 further includes compressed air or nitrogen supply 30, compressed air passage 32, headspace gas passage 34, discharge valve 36, liquid sensor 38, headspace gas discharge 40, flow passage 42, vessel scale 44 and system controller 46 .

[0013] The compressed air source 30 is connected to the compressed space 31 (ie, the space between the inner wall of the outer container 22 and the outer surface of the inner container 20 ) through a compressed air passage 32 . The interior of the inner container 20 is connected to a headspace gas outlet 40 through a gas passage 34 . A discharge valve 36 and a liquid sensor 38 are connected along the gas pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com