Thermal rotational molding technique and device for inner wall and outer wall of metal pipe

A technology of metal pipes, inner and outer walls, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of low production efficiency, difficult to guarantee the quality of rotomolding, high labor intensity, etc., to achieve product quality The effect of easy, high production efficiency and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As shown in Figure 13, the internal and external rotomolding process of the metal pipe of the present invention is divided into two processes: the inner wall rotomolding process and the inner and outer plastic rotomolding process, and the inner wall rotomolding process is as follows:

[0039]

[0040]

[0041] The outer wall thermal flow plastic process is as follows:

[0042]

[0043]

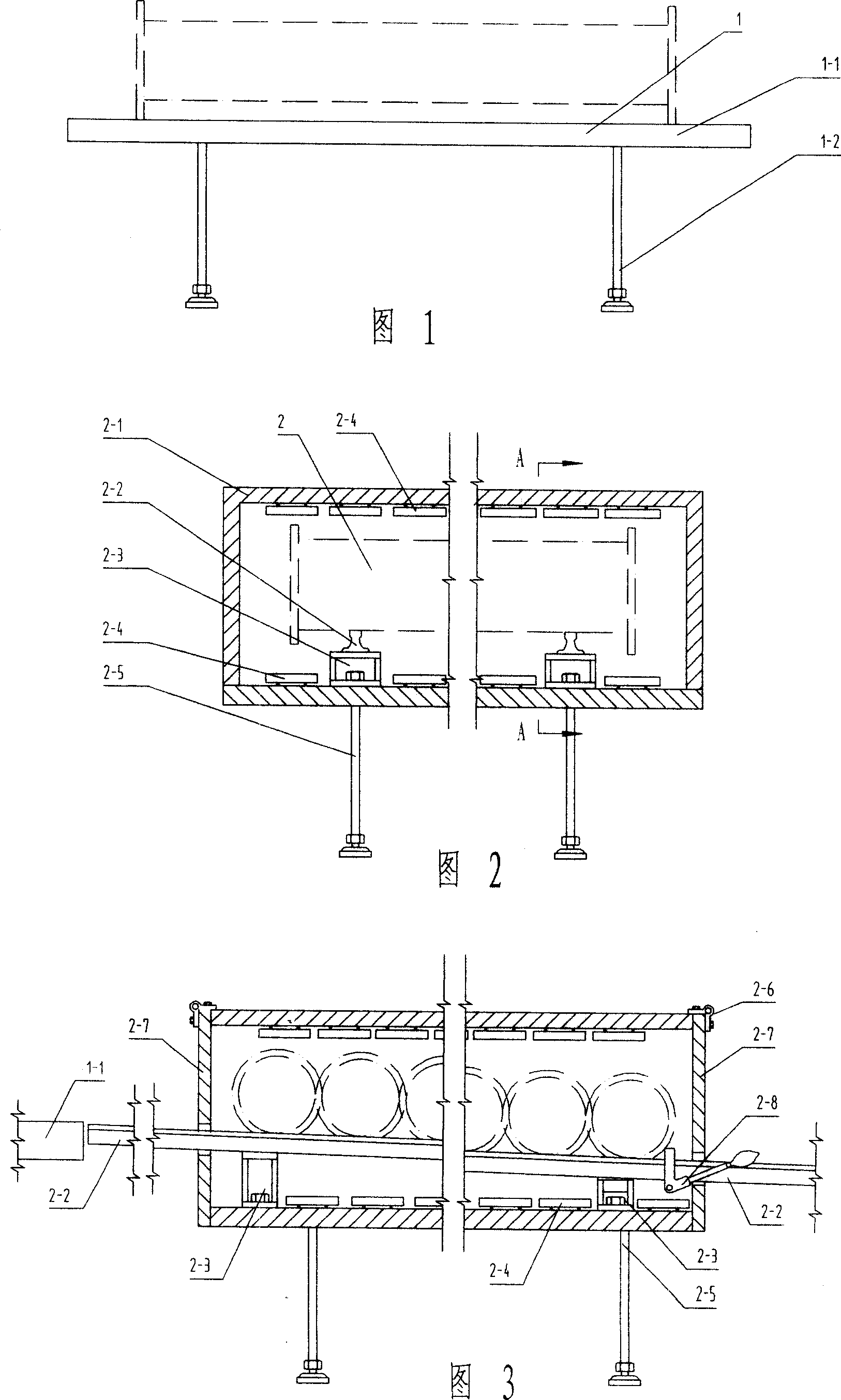

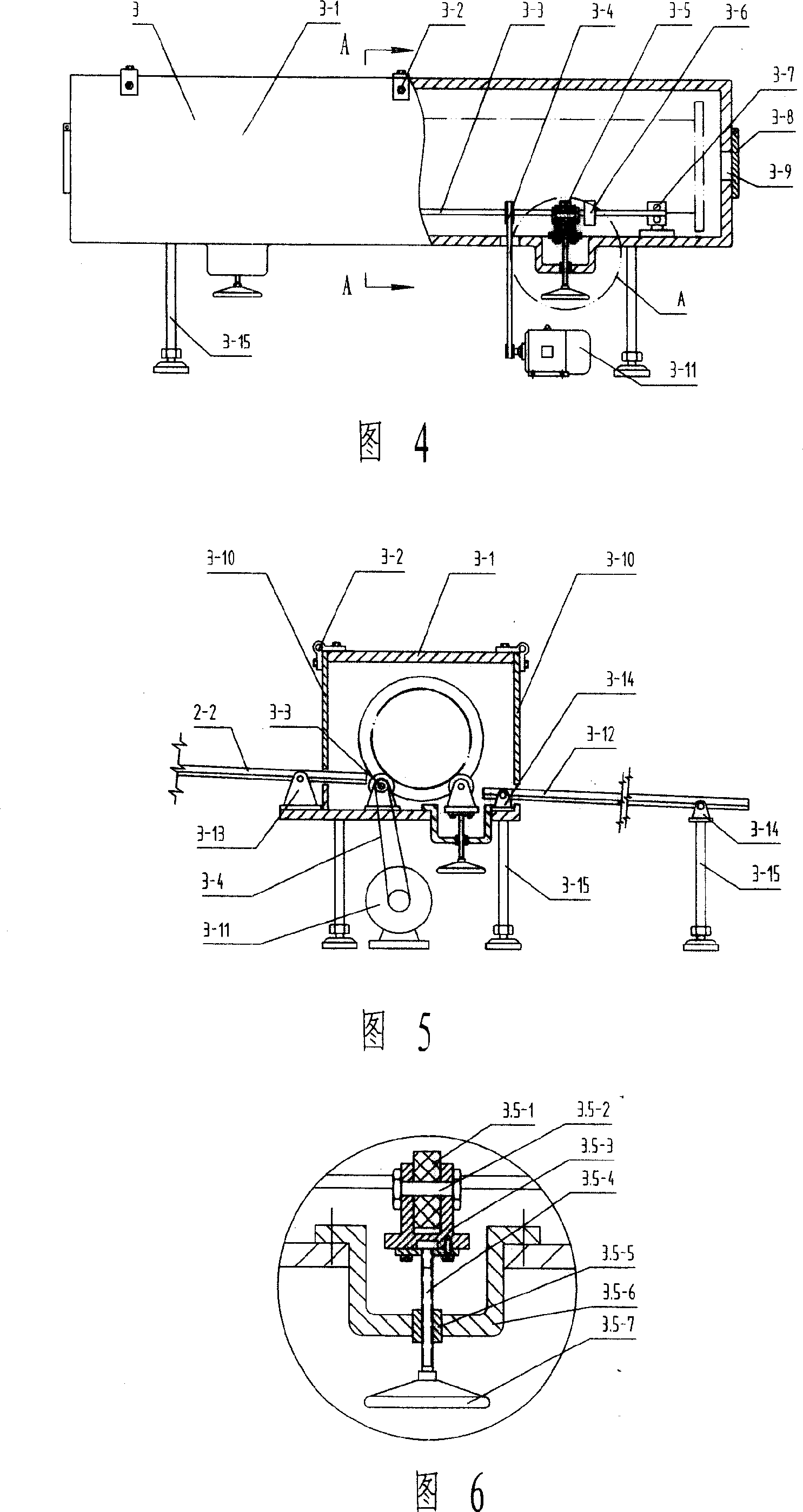

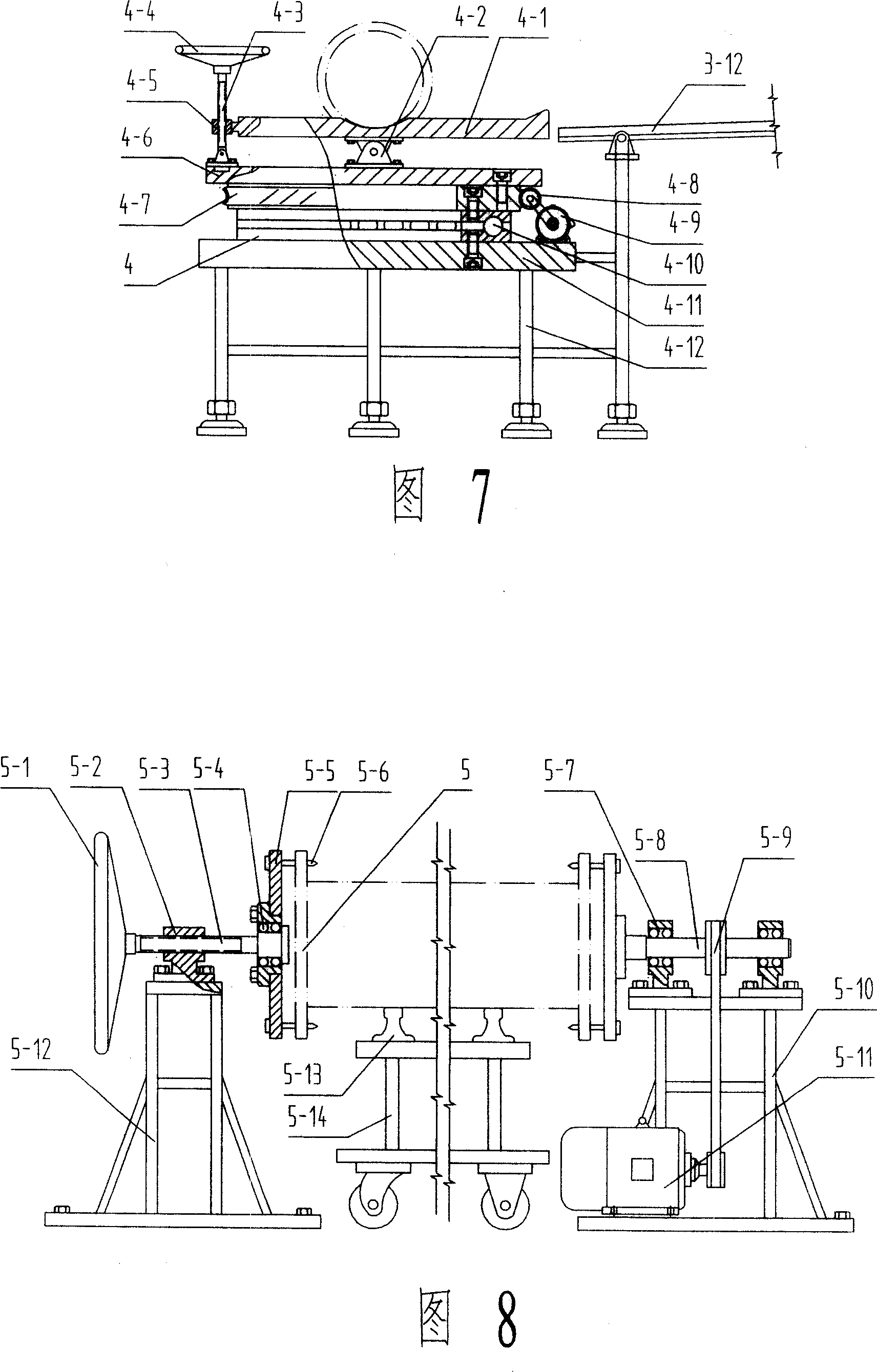

[0044] Before the metal pipe enters the assembly line, the processed pipe fittings are derusted first. The pre-rotomolding inspection platform 1 shown in FIG. 1 is composed of a rectangular table top 1-1 and legs 1-2. The height of the upper end of the table is equal to the upper end surface of the high end of the guide rail 2-2 in FIG. 3 . After passing the inspection, the pipe fittings are pushed onto the guide rail 2-2, and the guide rail 2-2 with an inclination of 8 is installed on the bottom plate of the heating furnace 2, and the pipe fittings will automatically roll i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com