Electric perforating method of seamless tube blank

A seamless pipe and seamless technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high processing cost, high mandrel consumption, slow speed, etc., to meet the requirements of continuous production process, realize The effect of automatic production and reduction of rolling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

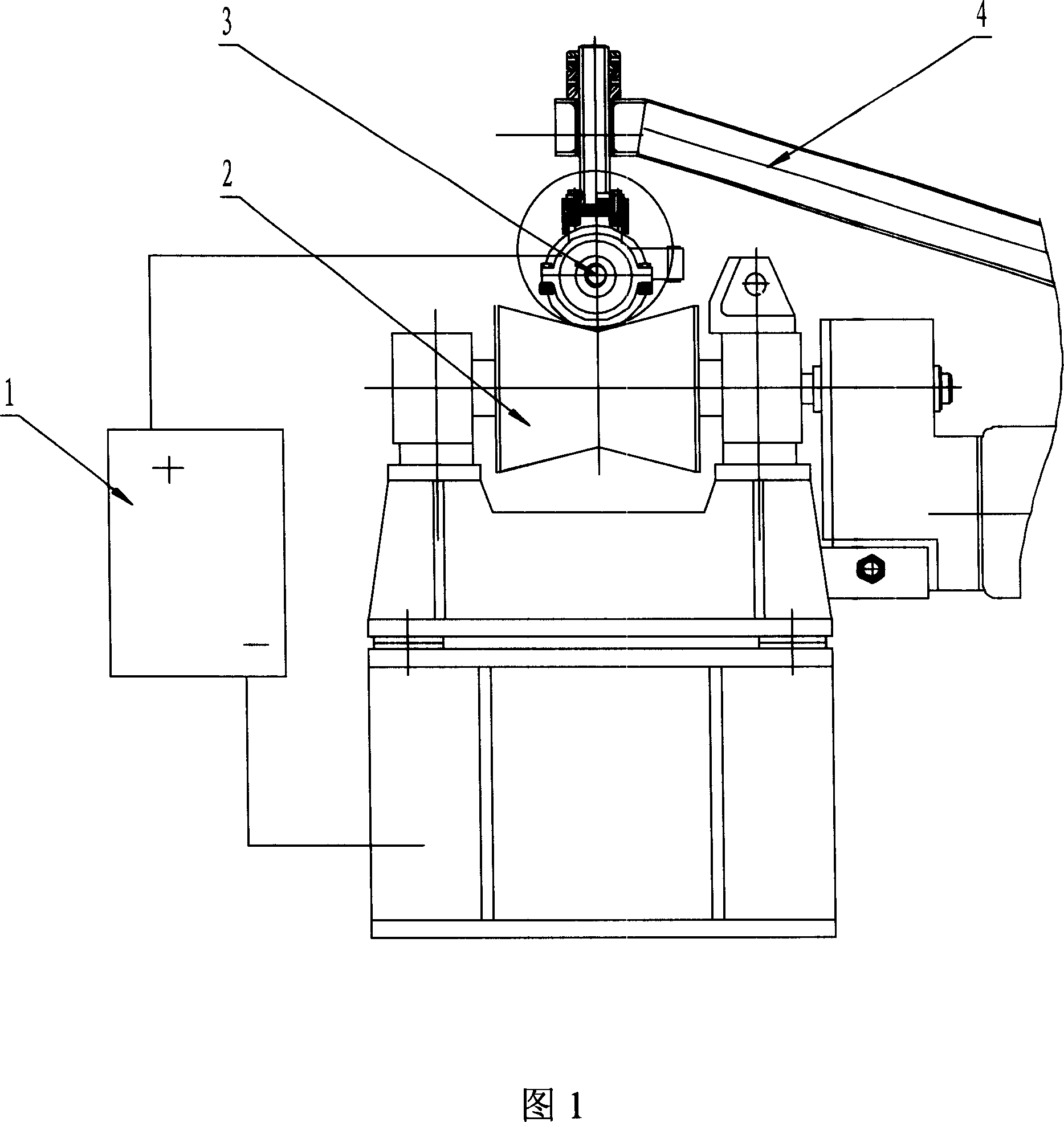

[0015] With reference to the accompanying drawings, the method of the present invention is: clamp a contact 3 made of carbon material (graphite) with a manipulator 4, and on the conveying roller table of the seamless tube blank 2, according to the diameter of the seamless tube blank, The manipulator 4 is controlled manually or by a programmable controller to adjust the position of the contact, so that the contact is aligned with the center of the tube blank, the manipulator 4 is lifted, the tube blank is transported by the roller table 2 to the punching position and stops, and a part of the power supply 1 One pole is connected with the contact 3, and the other pole is connected with the tube blank. The manipulator 4 falls, aligns with the center of the tube blank, and sends electricity to the contact 3. The billet generates an arc to melt the metal, and melts the end face of the tube blank into the hole required by the process. After the hole is punched, the contact 3 is powere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com