Method for prediction of oil well annular tube damage and detecting instrument for implementing the method

A detector and instrument technology, which is applied in earth-moving drilling, wellbore/well components, material magnetic variables, etc., can solve the problem of inability to predict casing damage, and achieve the effect of avoiding casing damage economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

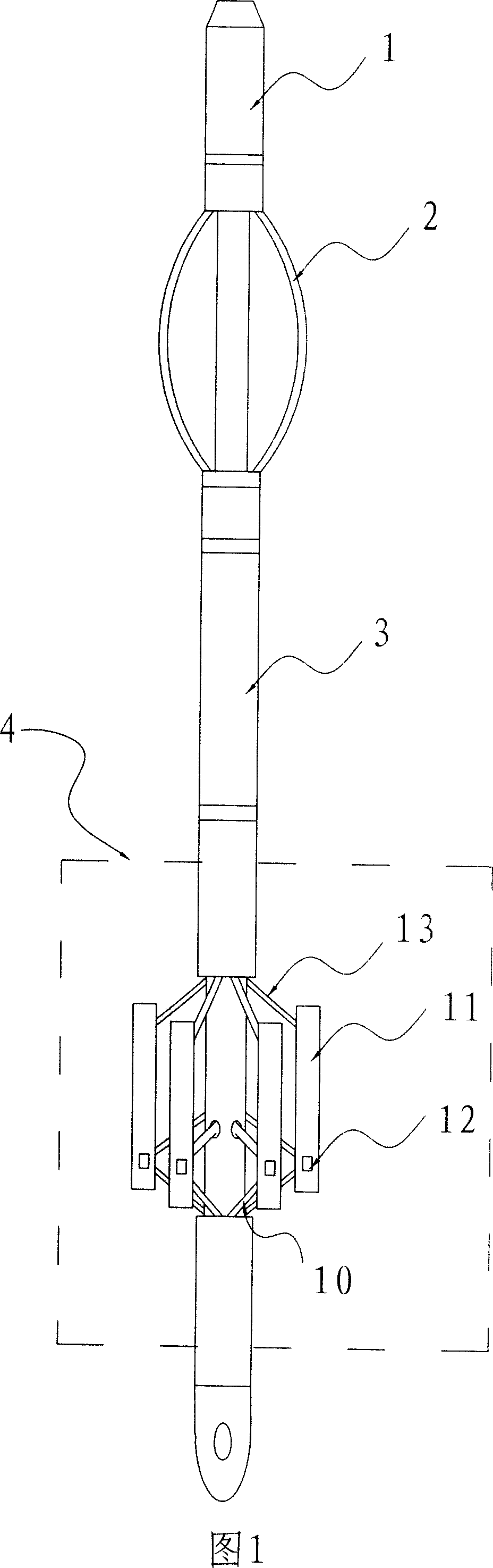

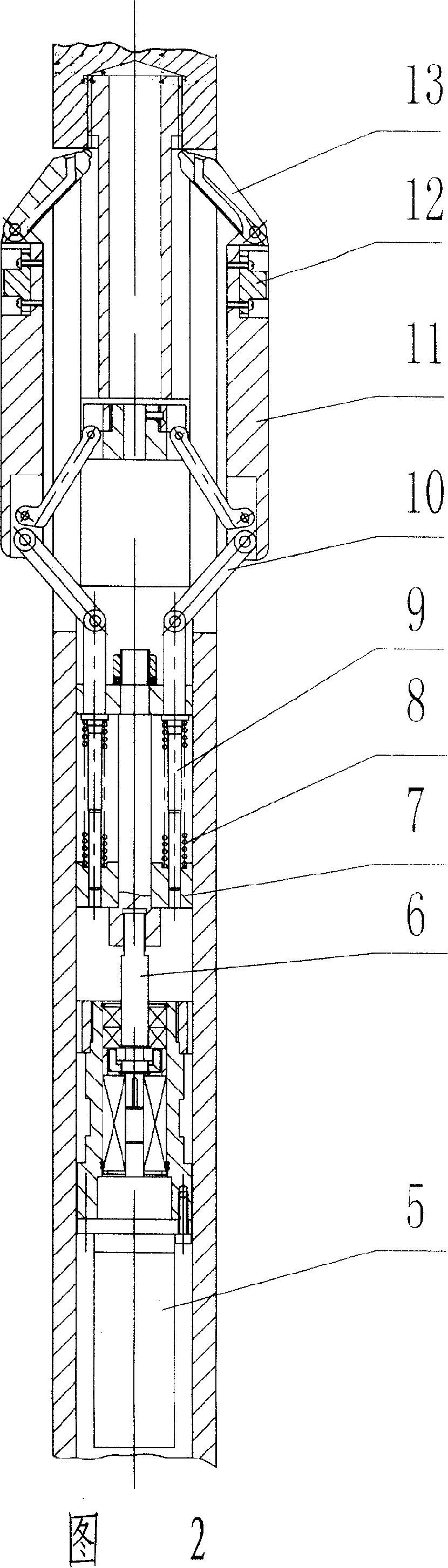

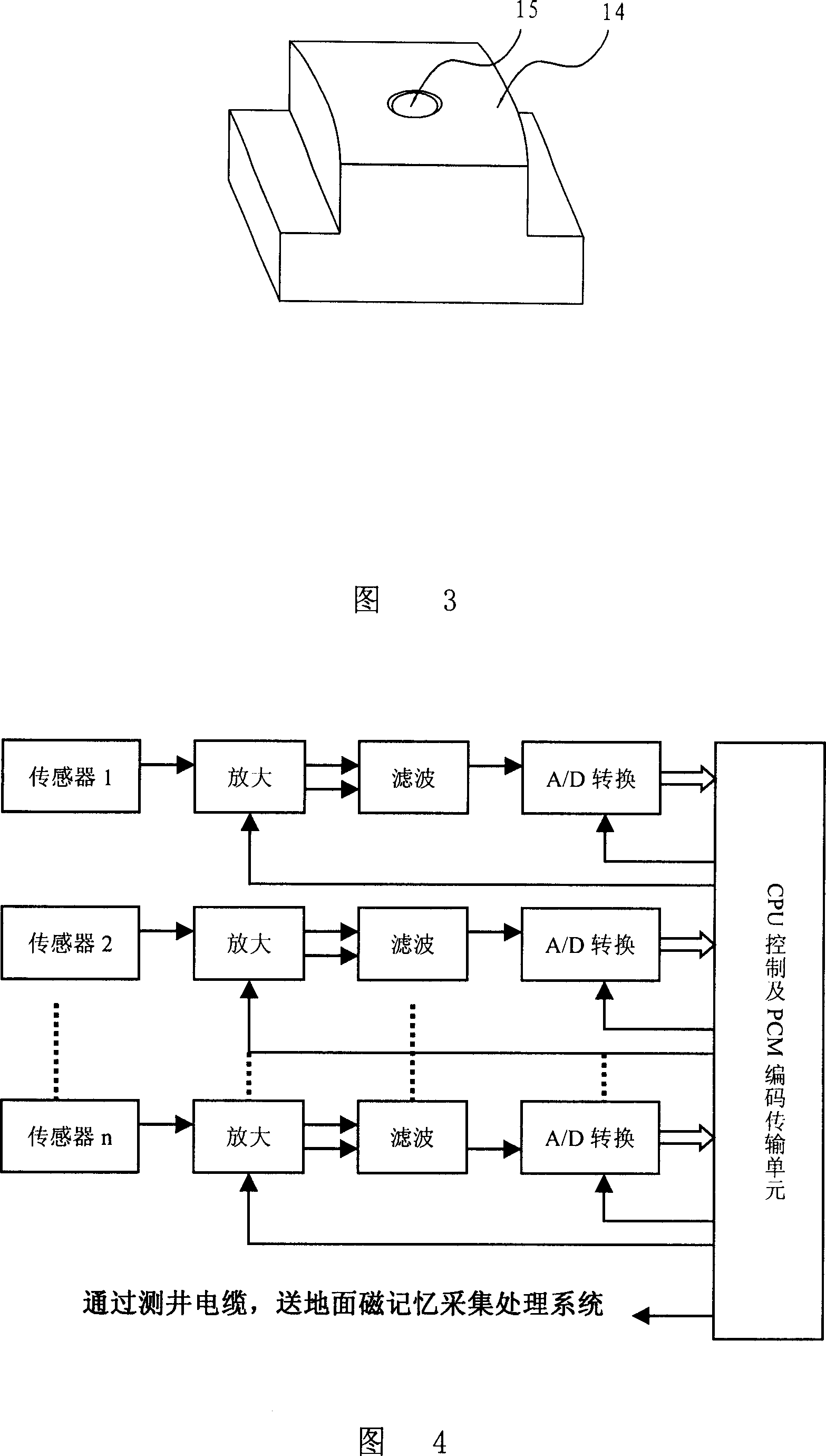

[0030] The present invention will be further explained below in conjunction with the accompanying drawings:

[0031] First, the principle of magnetic memory detection on which the present invention is based is introduced. Under the working load of the casing in the geomagnetic field, the surface of the stress concentration area will form a leakage magnetic field distribution form similar to the defect. The tangential component Hx of the magnetic field will have a maximum value, and the sign of the normal component Hy will change, and It has a zero-crossing value point, as shown in Fig. 5, in the figure, the X-axis of the abscissa is the scanning stroke distance (mm), and the Y-axis of the ordinate is the strength of the leakage magnetic field (A / m). The magnetic memory detection reflects the stress concentration of the component through the zero-crossing point of the normal component Hy of the leakage magnetic field and the K value, that is, the gradient change of the normal compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com