Damage monitoring method of composite material structure, and apparatus and system thereof

A technology for damage monitoring and composite materials, which is used in material analysis using acoustic emission technology, processing response signals of detection, etc., which can solve the problems of lack of mixed-signal separation methods, many types of structural damage, increased structural complexity and burden, etc. Achieve the effect of ensuring safety and economic benefits, reducing the loss of personnel and property, and reducing the complexity of hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

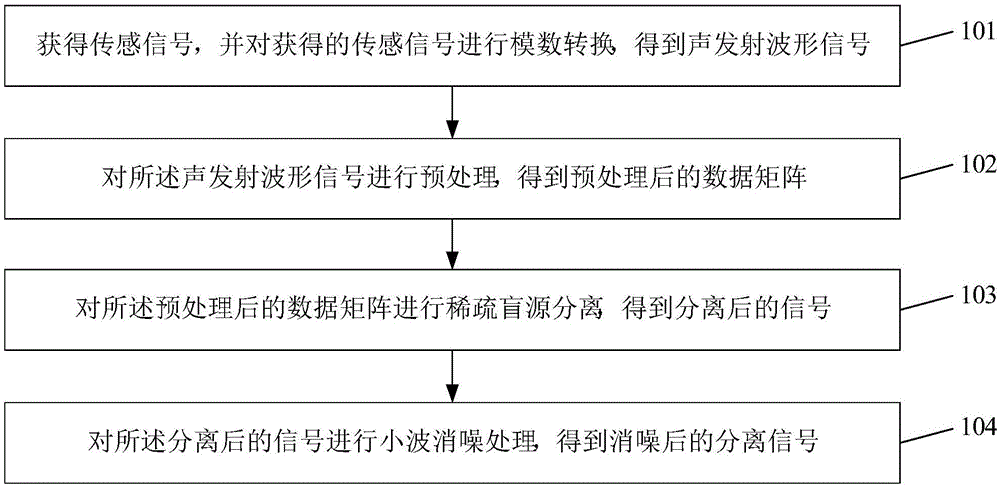

[0068] Embodiment 1 of the present invention provides a damage monitoring method for a composite material structure, such as figure 1 As shown, the method mainly includes:

[0069] In step 101, a sensing signal is obtained, and an analog-to-digital conversion is performed on the obtained sensing signal to obtain an acoustic emission waveform signal.

[0070] The sensing signal is a sensing signal obtained after the charge signal collected and output by the acoustic emission sensor is amplified by the charge amplifier. The embodiment of the present invention adopts at least two acoustic emission sensors to collect acoustic emission charge signals on the composite material structure, and the acoustic emission charge signals are usually aliasing of multiple types of damage signals.

[0071] After the sensing signal is obtained, the sensing signal is converted from an analog signal to a digital signal to obtain an acoustic emission waveform signal.

[0072] Step 102, performing ...

Embodiment 2

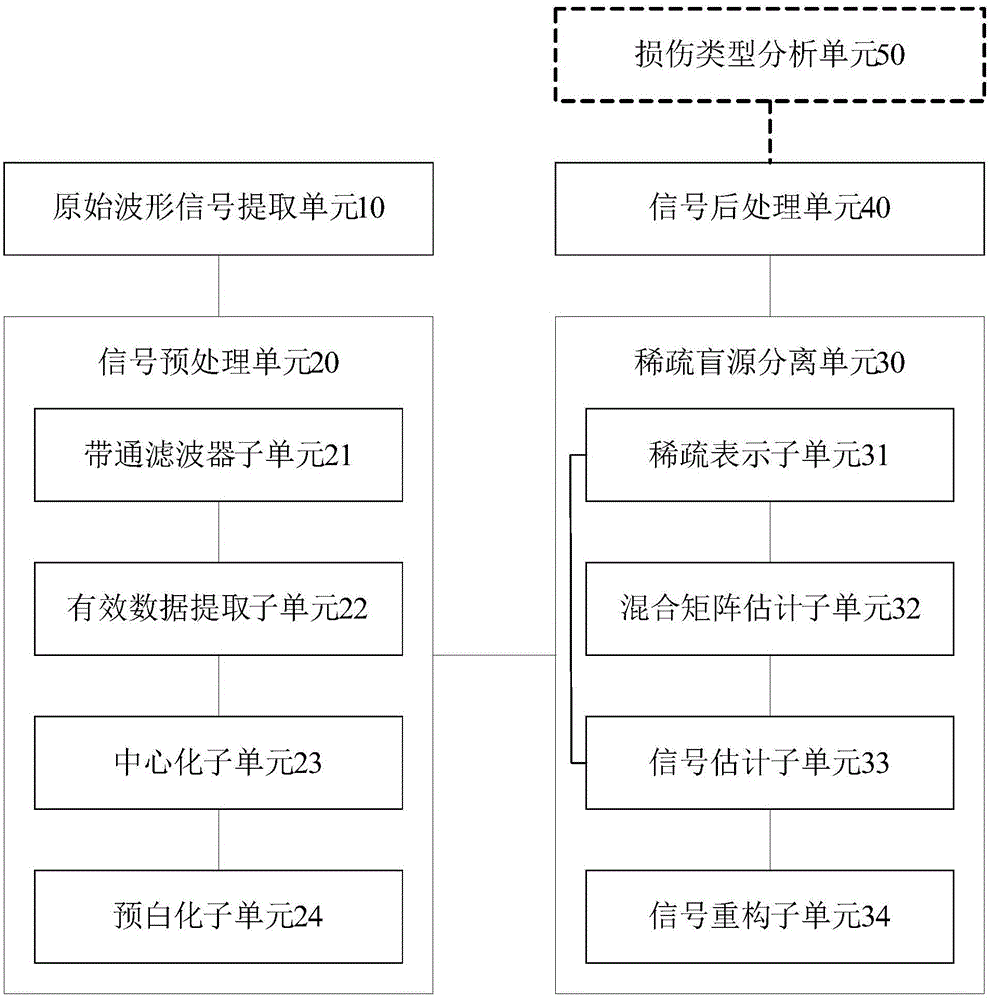

[0110] Corresponding to the damage monitoring method of the composite material structure in the first embodiment of the present invention, the second embodiment of the present invention provides a damage monitoring device for the composite material structure, such as figure 2As shown, the device includes:

[0111] The original waveform signal extraction unit 10 is used to obtain the sensing signal, and perform analog-to-digital conversion on the obtained sensing signal, and output the acoustic emission waveform signal;

[0112] A signal preprocessing unit 20, configured to preprocess the acoustic emission waveform signal, and output a preprocessed data matrix;

[0113] A sparse blind source separation unit 30, configured to perform sparse blind source separation on the preprocessed data matrix, and output separated signals;

[0114] The post-processing unit 40 is configured to perform wavelet denoising processing on the separated signal to obtain a denoised separated signal....

Embodiment 3

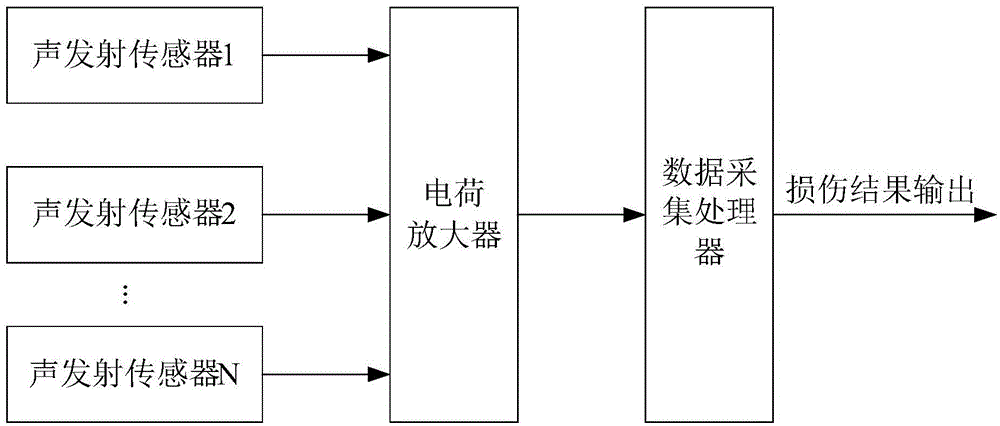

[0130] Embodiment 3 of the present invention also provides a damage monitoring system for a composite material structure, such as image 3 As shown, the system includes: at least two acoustic emission sensors, a charge amplifier and a data acquisition processor; wherein,

[0131] The acoustic emission sensor is used to collect the acoustic emission signal for the composite material structure and output it to the charge amplifier;

[0132] The charge amplifier is used to amplify the acoustic emission signal output by the acoustic emission sensor, and output the sensing signal to the data acquisition processor;

[0133] The data acquisition processor is used to obtain the sensing signal, and perform analog-to-digital conversion on the obtained sensing signal to obtain an acoustic emission waveform signal; perform preprocessing on the acoustic emission waveform signal to obtain a preprocessed data matrix ; performing sparse blind source separation on the preprocessed data matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com