Method for fabricating highly effective generator and highly effective generator

A manufacturing method and generator technology are applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. Efficiency, drag reduction, ease of manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

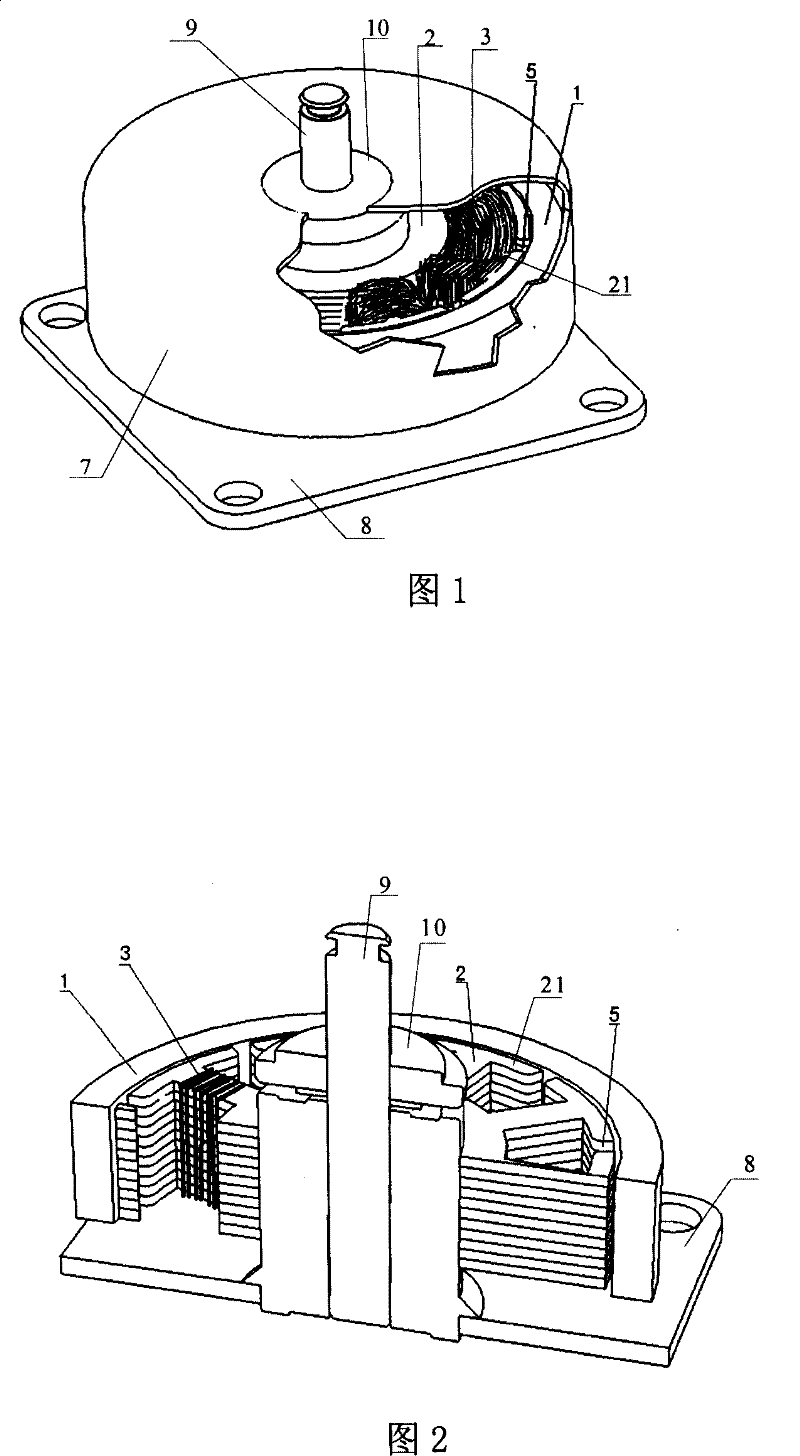

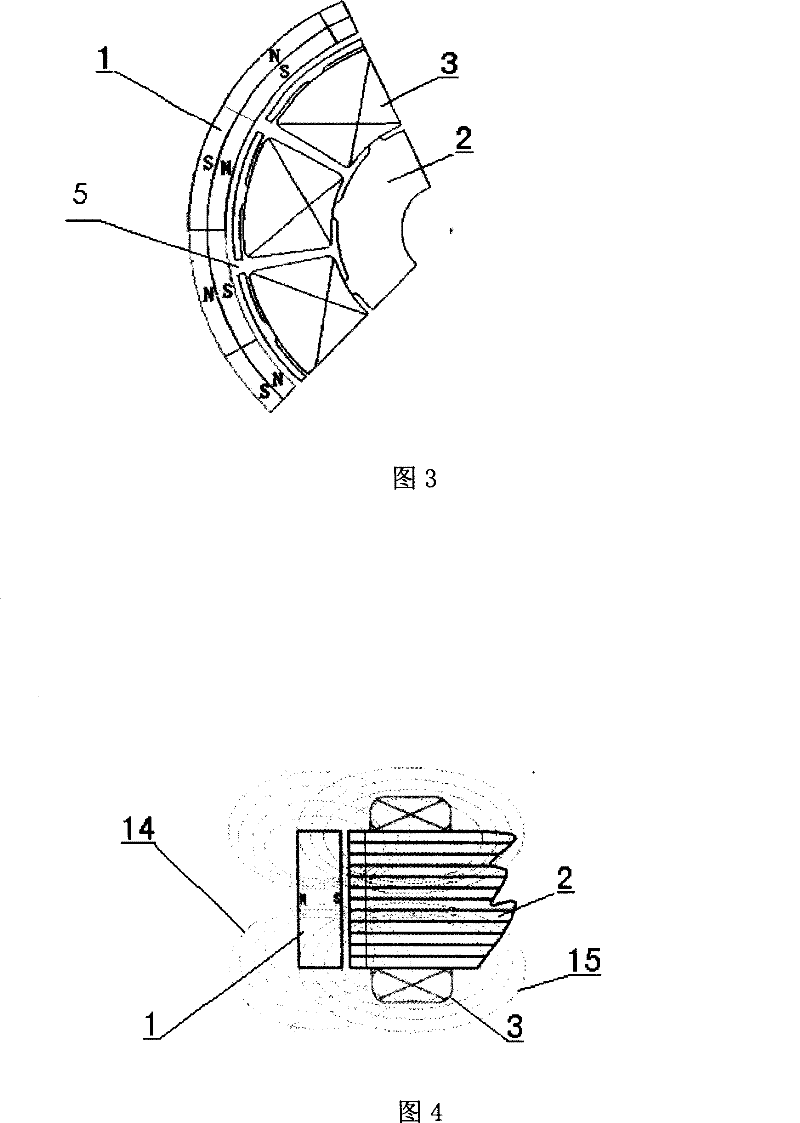

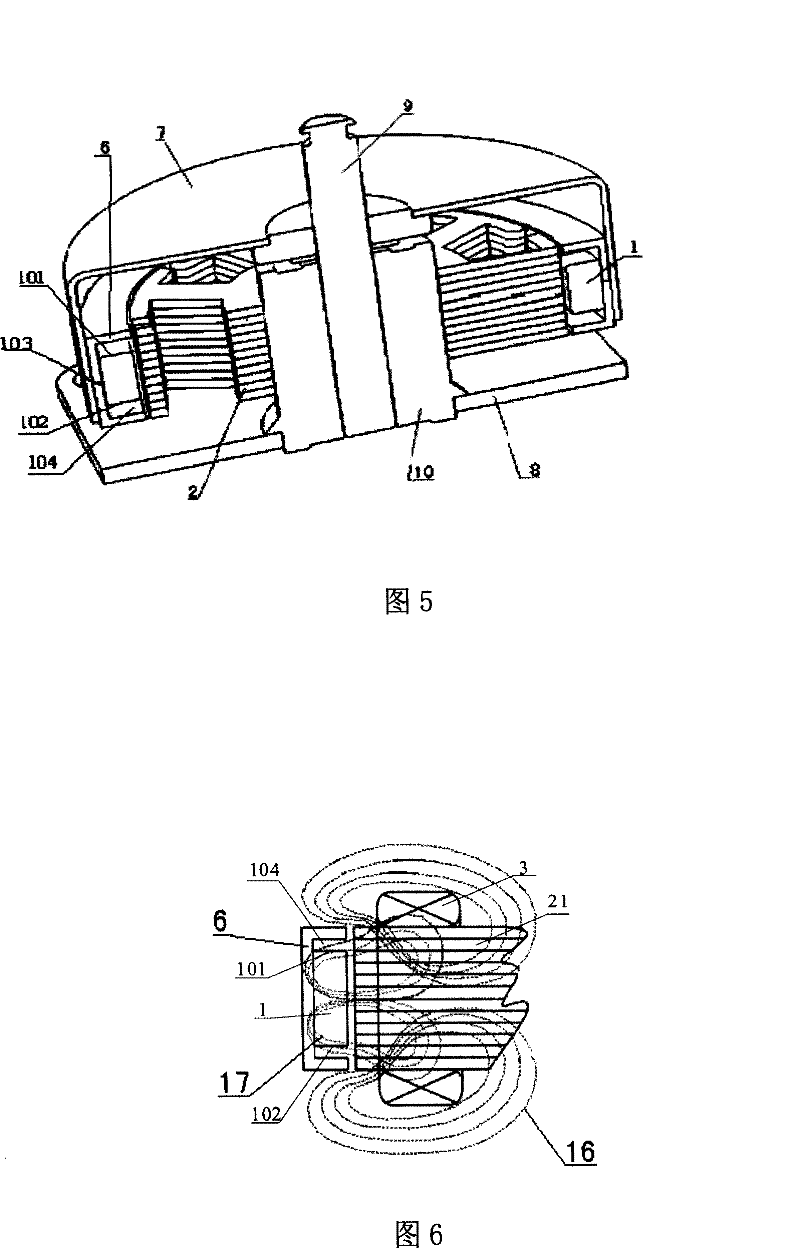

[0025] Embodiment 1, a high-efficiency generator and its manufacturing method, such as Figure 5 Shown is right figure 1 Schematic diagram of the structure of the shown generator after partial improvement. The improvement is that a shielding ring 6 is fixed on the upper and lower sides and the back side 103 of the ring-shaped permanent magnet 1, and the axial section of the shielding ring 6 along the central axis has a "]"-shaped structure. The axial distance is equal to the axial thickness of the iron core of the winding wire package, wherein there is a gap 104 between the upper and lower sides (101, 102) of the permanent magnet 1 and the shielding ring 6, so that the magnetic force lines of the rotating magnetic field enter The iron core 2 is lower than the thickness of the iron core 2. The shielding ring 6 must be made of magnetically permeable materials such as iron or ferrite. other structures with figure 1 The existing structure shown is identical. Figure 6 A schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com