Light emitting element with a plurality of cells bonded, method of manufacturing the same, and light emitting device using the same

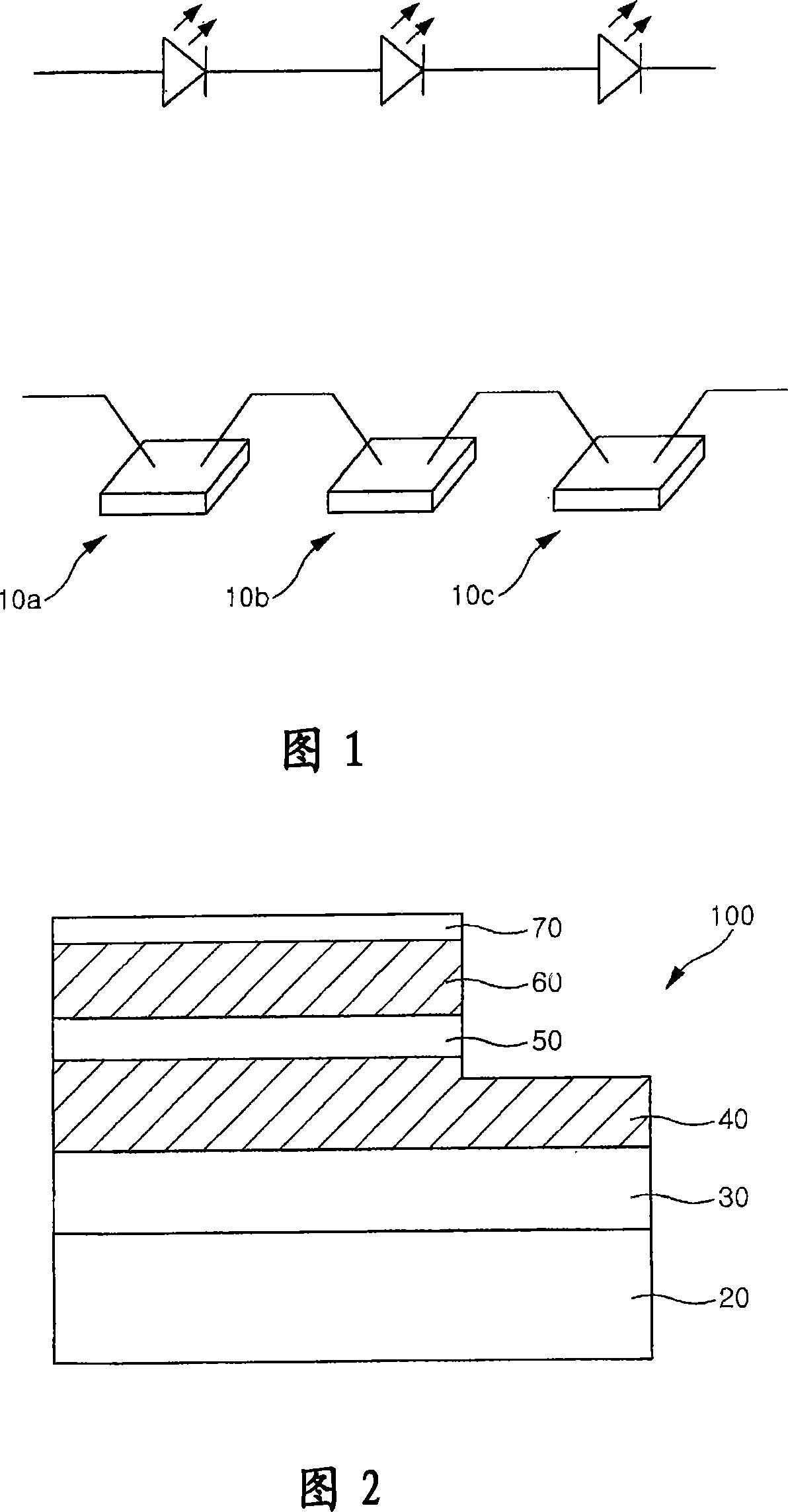

A technology for light-emitting elements and light-emitting units, which is applied in the use of semiconductor lamps, electrical components, semiconductor devices, etc., can solve problems such as difficulty in control, interference in the overlapping area of leads, and unsuitable lighting devices for lighting, etc., to simplify the manufacturing process, reduce The effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the embodiments, but can be constructed in various forms. These examples are provided for illustrative purposes only and for those skilled in the art to fully understand the scope of the present invention. Throughout the drawings, like components are indicated by like reference numerals.

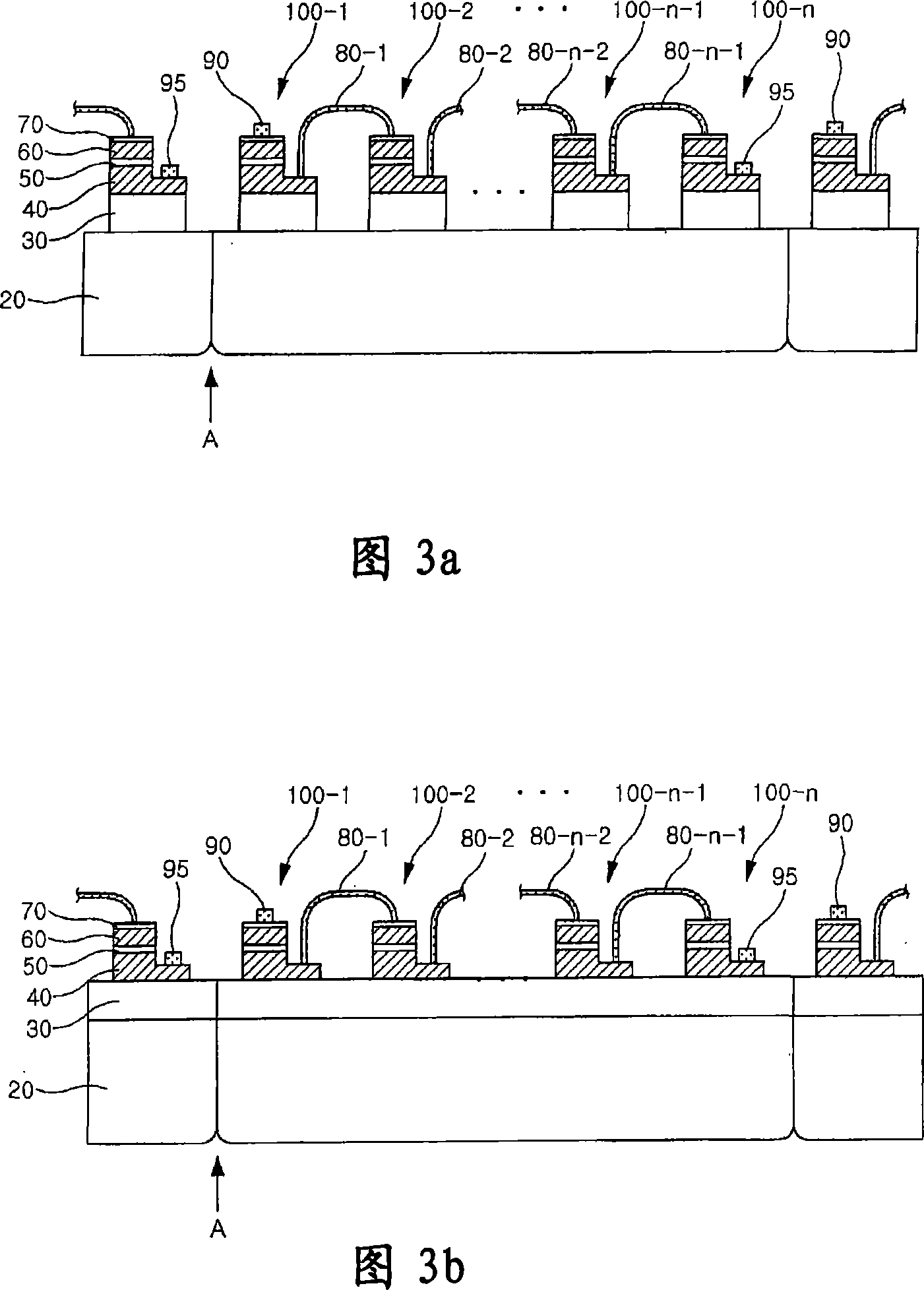

[0036] FIG. 2 is a cross-sectional view of an individual light emitting unit according to an embodiment of the present invention.

[0037] Referring to Fig. 2, light-emitting unit 100 comprises: substrate 20; Buffer layer 30, N-type semiconductor layer 40, active layer 50 and P-type semiconductor layer 60 laminated on substrate 20 sequentially; Formed on N-type semiconductor layer 40 N-type bonding pads (see reference numeral 95 in FIG. 3 a ) on the exposed area of the exposed region; and P-type bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com