Controlling device for electrodeposition process

A technology of process control and electrodeposition, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of unsuitable industrial production, discomfort of electroplating equipment, and very high comprehensive performance requirements of the deposition layer, so as to improve the degree of automation and improve the uniformity Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

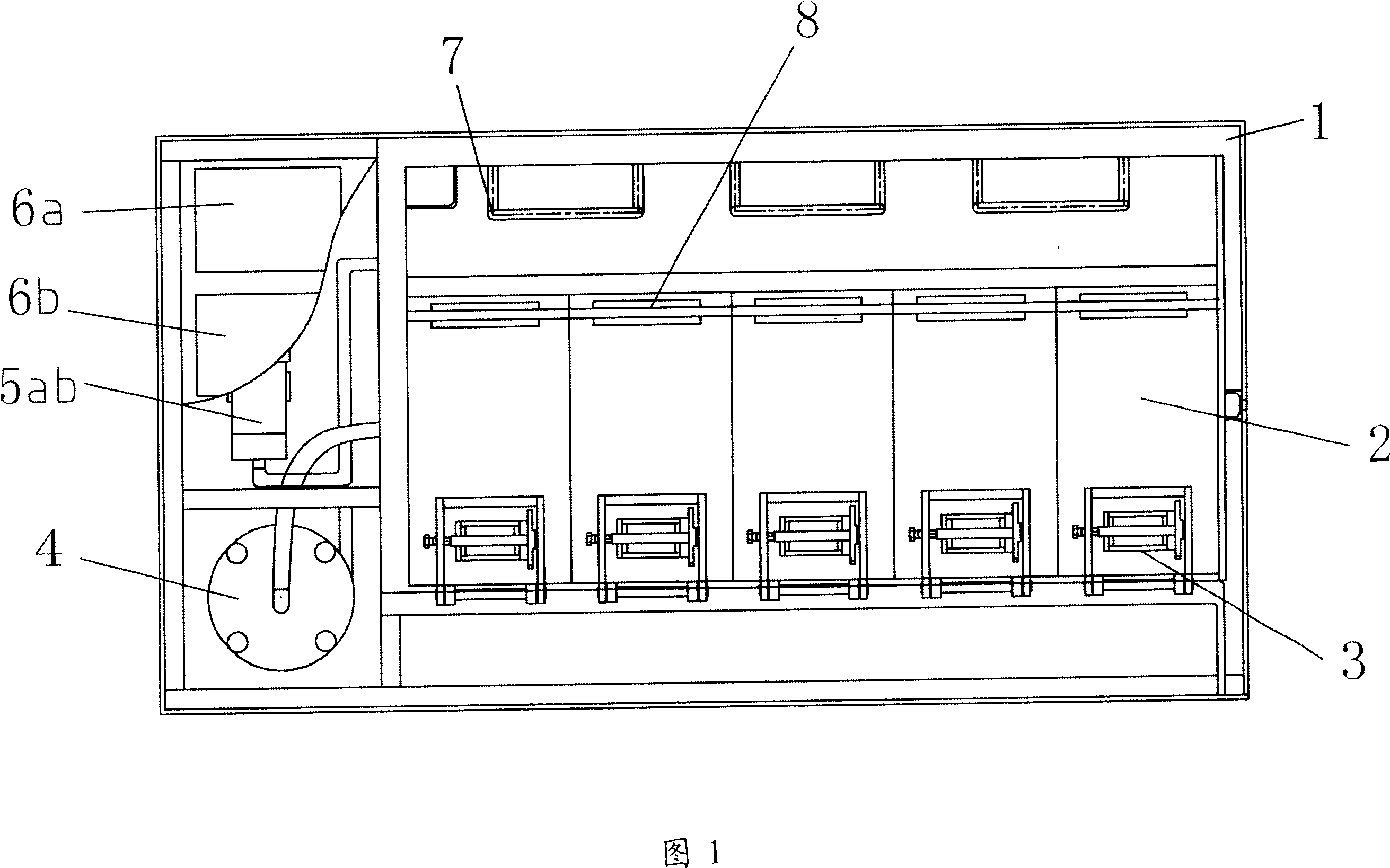

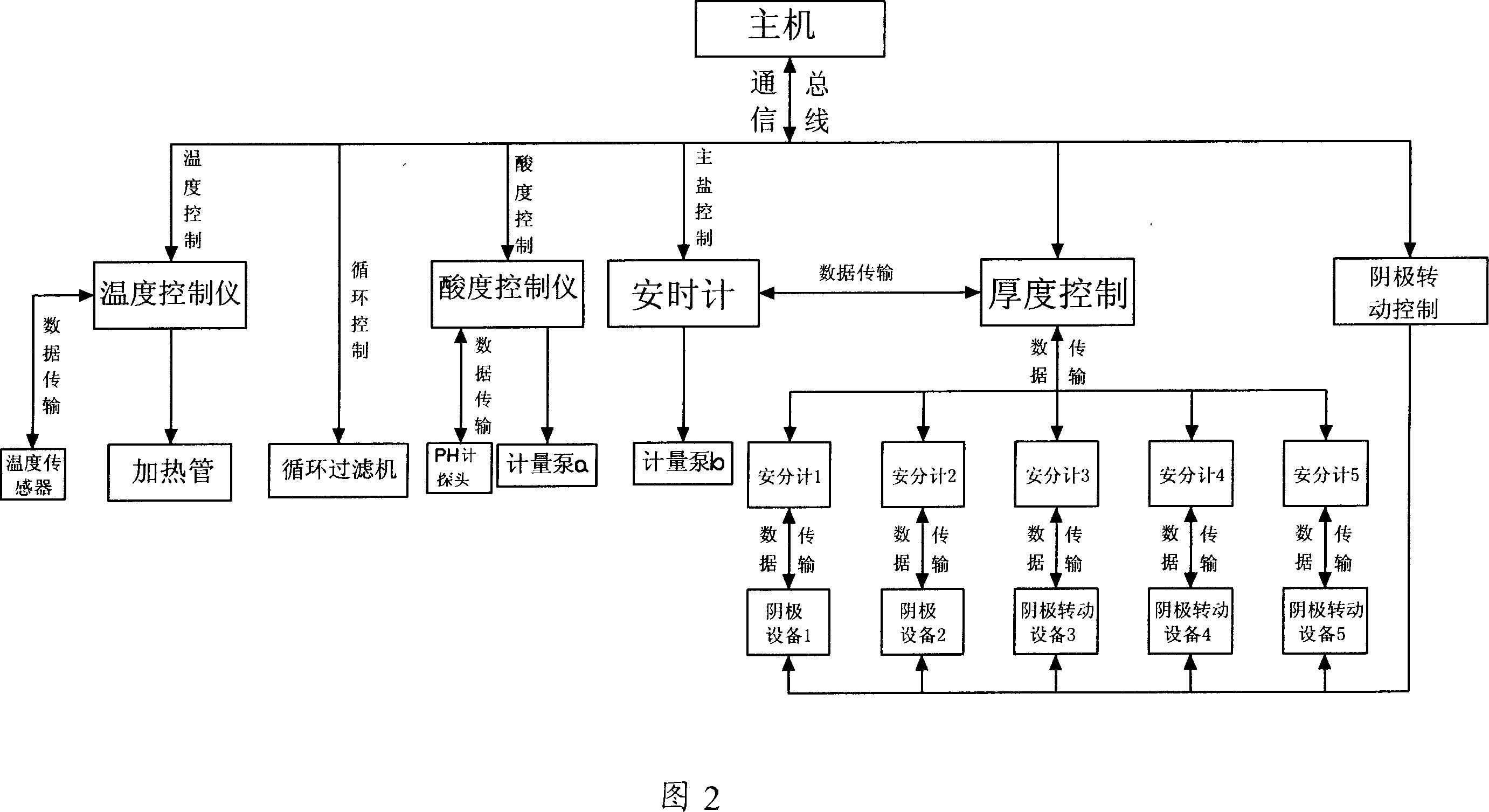

[0017] The electrodeposition process control equipment includes two parts, the working tank and the console. The console includes the working host, the operation panel and the electric control box. It is characterized in that the equipment casing 1 has a removable top cover. The tank 2 contains the electrolyte, and the tank is divided into multiple stations by the frame, and each station is respectively provided with an anode frame 8 and a cathode rotating device 3; one side of the working tank 2 is equipped with a heating tube 7 and a temperature sensor. The pipeline is connected with the circulating filter 4 outside the tank and the metering pumps 6a and 6b; the condition treatment tank 5a in the housing 1 is located at one end of the working tank, which contains the pH value adjustment liquid and is connected with the metering pump 6a, and the condition tank 5b is located at the condition tank 5a The lower part contains the main salt supplement solution and is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com