A dust generation system and its treatment method

A technology of dust generation and dust, which is applied in the field of air pollution research, can solve the problems of poor dust selectivity, inconvenient control, lack of accuracy, etc., and achieve the effect of reducing equipment space, avoiding waste, and maintaining uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

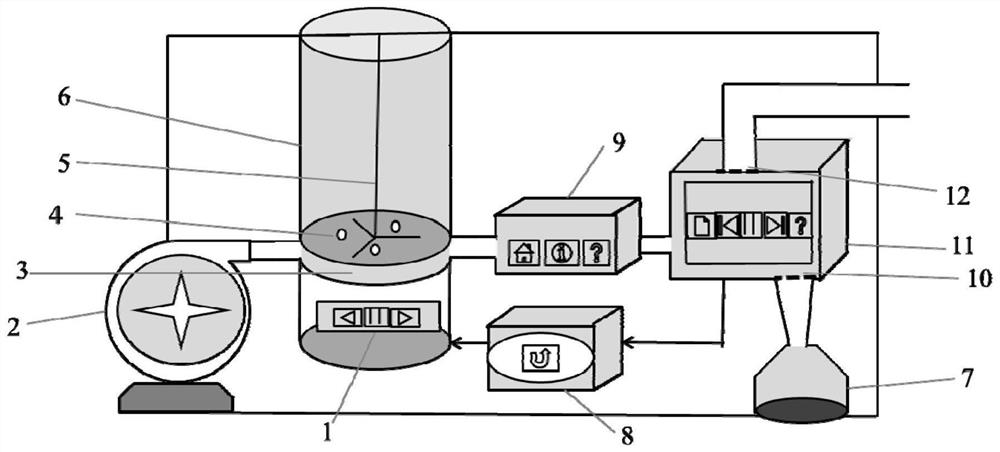

[0042] The present invention provides a dust generation system, the device connection schematic diagram is as follows figure 1As shown, the system includes an airflow generating device 2, a dust generating device, a concentration sensor 9, a control system 11, a feedback system 8, and an aperture regulator 1, and the dust generating device includes a dust container 6 and a dust generating bin 3. The dust container 6 is located above the dust generating bin 3, the air flow generating device 2, the dust generating bin 3, the concentration sensor 9, the control system 11, the feedback system 8 and the aperture regulator 1 are connected in sequence, and the dust container 6 The bottom is provided with a dust flow hole 4, and the aperture regulator 1 is connected with the dust flow hole 4.

[0043] Wherein, the air flow generating device 2, the dust generating chamber 3, the concentration sensor 9 and the control system 11 are sequentially connected through a conveying pipe, and th...

Embodiment 2

[0049] The present invention provides a method for generating dust, which is carried out using the system in Example 1, and the method comprises the following steps:

[0050] (1) The dust in the dust container 6 enters the dust generating chamber 3 through the dust flow hole 4 and is ejected by the blower, and the dust enters the concentration sensor 9, and the dust concentration is converted into an electrical signal;

[0051] (2) The dust in step (1) and its electric signal enter the control system 11, when the dust concentration meets the concentration set in the control system 11, the first dust outlet switch 12 of the control system 11 is opened, and the second outlet The dust switch 10 is closed, and the dust is discharged from the first dust outlet switch 12; when the dust concentration does not meet the concentration set in the control system 11, the first dust outlet switch 12 of the control system 11 is closed, and the second dust outlet The switch 10 is opened, and ...

Embodiment 3

[0056] The present invention provides a kind of dust generation method, described method adopts the system in embodiment 1 to carry out, and described method refers to the method in embodiment 2, difference is: set dust generation concentration to be 2g / m 3 , the blower blowing pressure is 1.0MPa, and the diameter of the dust flow hole 4 is manually adjusted to 3mm.

[0057] After automatic adjustment by the system, the dust concentration at the first dust outlet switch 12 reaches the set value; the dust concentration measured at the system outlet is 1.982g / m 3 , the error is only 0.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com