Automatic polishing solution supply device for quartz ring for semiconductor

An automatic supply and polishing liquid technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, mixers with rotating stirring devices, etc., can solve the problem of affecting polishing accuracy, reducing polishing efficiency, and affecting marble and quartz rings. Surface shape and other problems, to achieve the effect of improving polishing efficiency, improving polishing accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the present invention will be further elaborated below in conjunction with specific drawings.

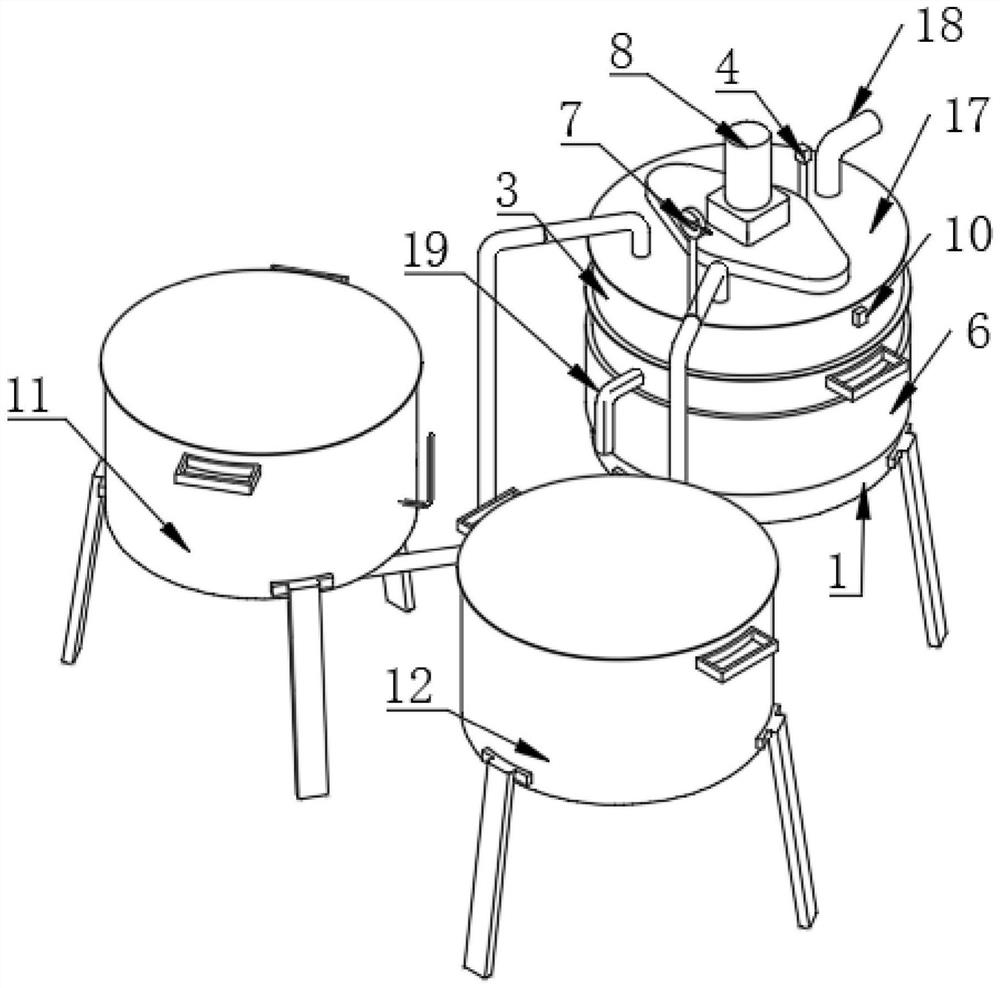

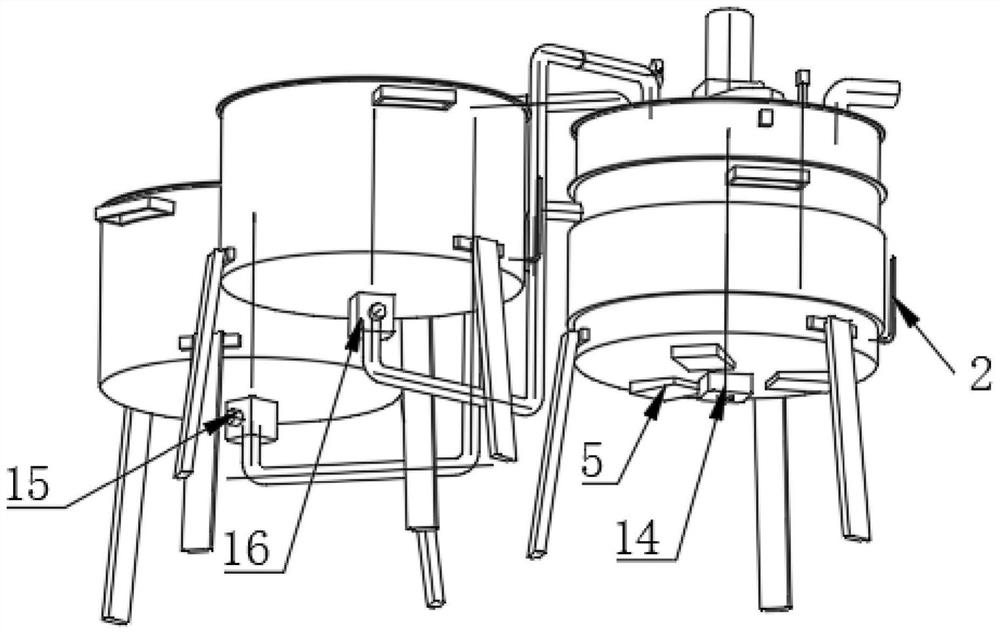

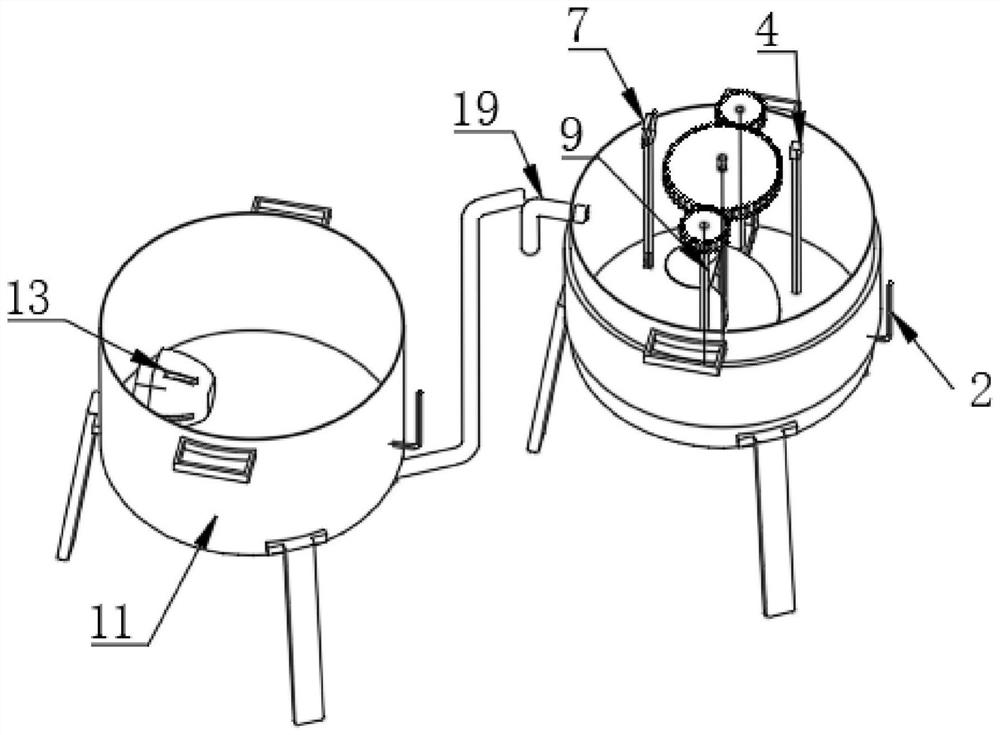

[0034] refer to Figure 1 to Figure 5 , an automatic polishing liquid supply device for quartz rings for semiconductors, including a polishing liquid bucket 1, a water level gauge 2, a filter screen 3, a temperature sensor 4, a semiconductor refrigeration block 5, thermal insulation cotton 6, a tuning fork type density meter 7, a stirring Device, vibrator 10, pure water bucket 11, stock solution bucket 12, wave pump 13, polishing liquid supply pump 14, pure water pump 15, polishing liquid regulating pump 16, polishing liquid barrel cover 17, polishing liquid return port 18, overflow port 19 . Stirring device comprises stirring motor 8, three stirrers 9.

[0035] The polishing liquid bucket cover 17 is positioned at the top of the polishing liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com