Method for estimating and monitoring dielectric film quality and reliability

A dielectric layer and reliability technology, applied in the field of reliability of microelectronic products, can solve the problem of not being able to quickly and clearly reflect the nature of dielectric layer process defects, and achieve the effect of simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

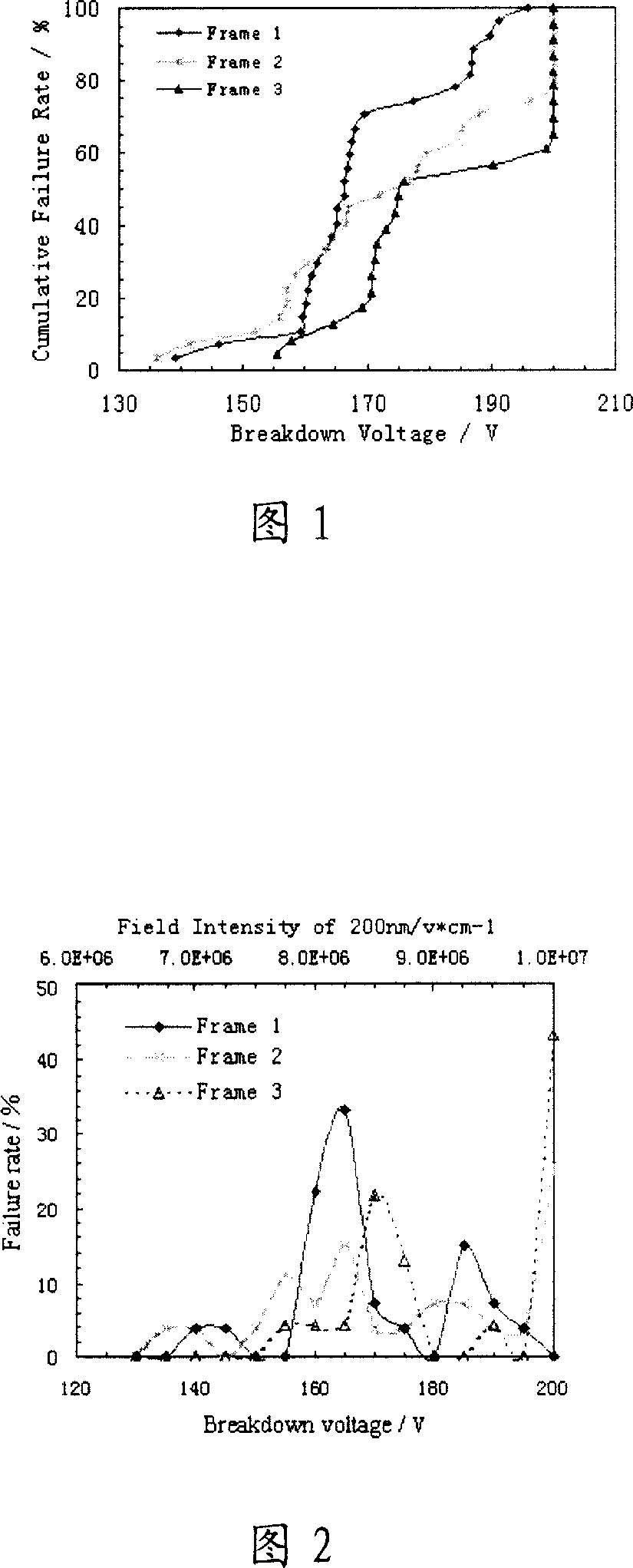

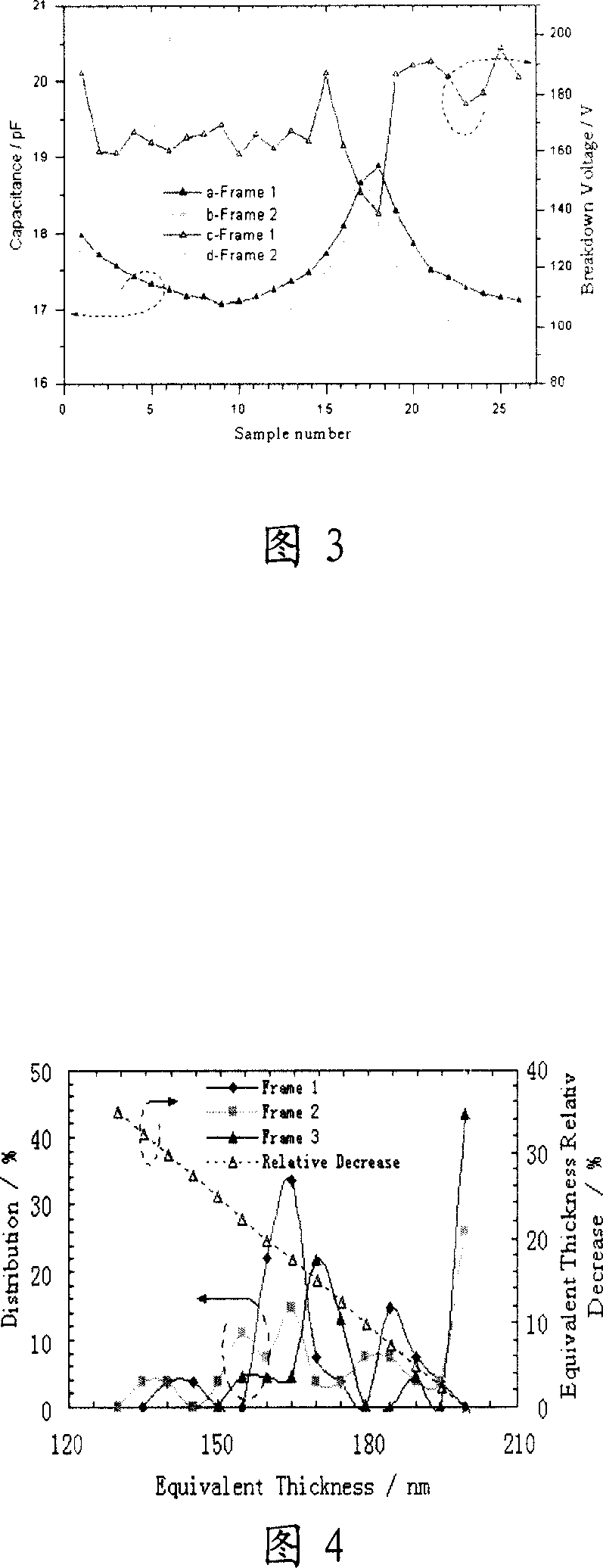

[0020] The method for evaluating and monitoring the quality and reliability of the medium layer of the present invention comprises the following steps:

[0021] (1) First set the defect to cause the breakdown of the measured dielectric layer to be electric field breakdown;

[0022] (2) Applying an electric field to the measured dielectric layer causes the dielectric layer to break down to obtain a breakdown voltage V BD , breakdown voltage V BD Over 200V is regarded as 200V;

[0023] (3) Set the dielectric strength of the measured medium layer as E DS , dielectric strength E DS It is a fixed value under certain process conditions, and it is obtained by converting the maximum breakdown voltage or using the data of reference materials;

[0024] (4) Get the equivalent thickness d of the measured medium layer EQ equal to the breakdown voltage V BD and dielectric strength E DS ratio of

[0025] (5) The equivalent thickness d EQ Compared with the design thickness of the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com