Ceramic metal halid light and its making technology of the electrode component

A halide lamp, ceramic metal technology, applied in electrode assembly manufacturing, gas discharge lamp parts and other directions, can solve the problems of high processing cost and low production efficiency, achieve cost reduction, low investment in manufacturing equipment, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

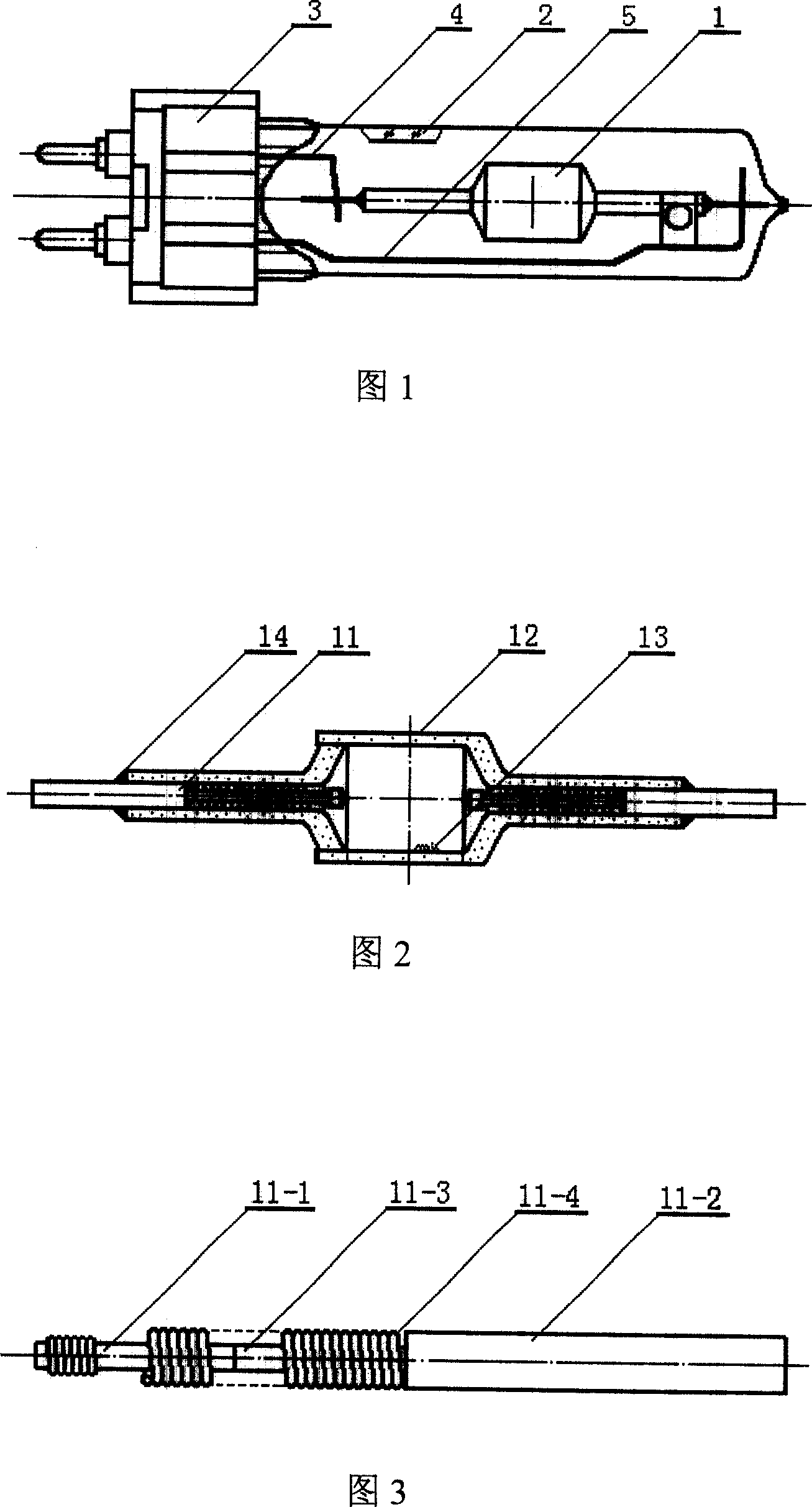

[0026] The power is a ceramic metal halide lamp of 150 watts, the electrode rod of the tungsten electrode 11-1 in the electrode assembly and the transitional molybdenum wire 11-3 have the same diameter of 0.50 mm, the inner diameter of the molybdenum spiral 11-4 is 0.52 mm, and the outer diameter is 0.86 mm. mm, the diameter of the niobium lead wire 11-2 is 0.90 mm; the electrode assembly 11 of a 150-watt ceramic metal halide lamp is manufactured by using the aforementioned manufacturing method.

Embodiment 2

[0028] The power is a ceramic metal halide lamp of 70 watts, the diameter of the tungsten electrode 11-1 and the transitional molybdenum wire 11-3 in the electrode assembly are both 0.40 mm, the inner diameter of the molybdenum spiral 11-4 is 0.42 mm, and the outer diameter is 0.66 mm. mm, the diameter of the niobium lead wire 11-2 is 0.70 mm; the electrode assembly 11 of a 70-watt ceramic metal halide lamp is manufactured by the same manufacturing method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap