Method for control of a pressurised air supply system for a motor vehicle

A technology of compressed air and supply system, applied in the direction of pump/compressor arrangement, etc., can solve the problems of motor vehicle speed loss, air compressor power consumption not being targeted to save energy, low motor vehicle speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

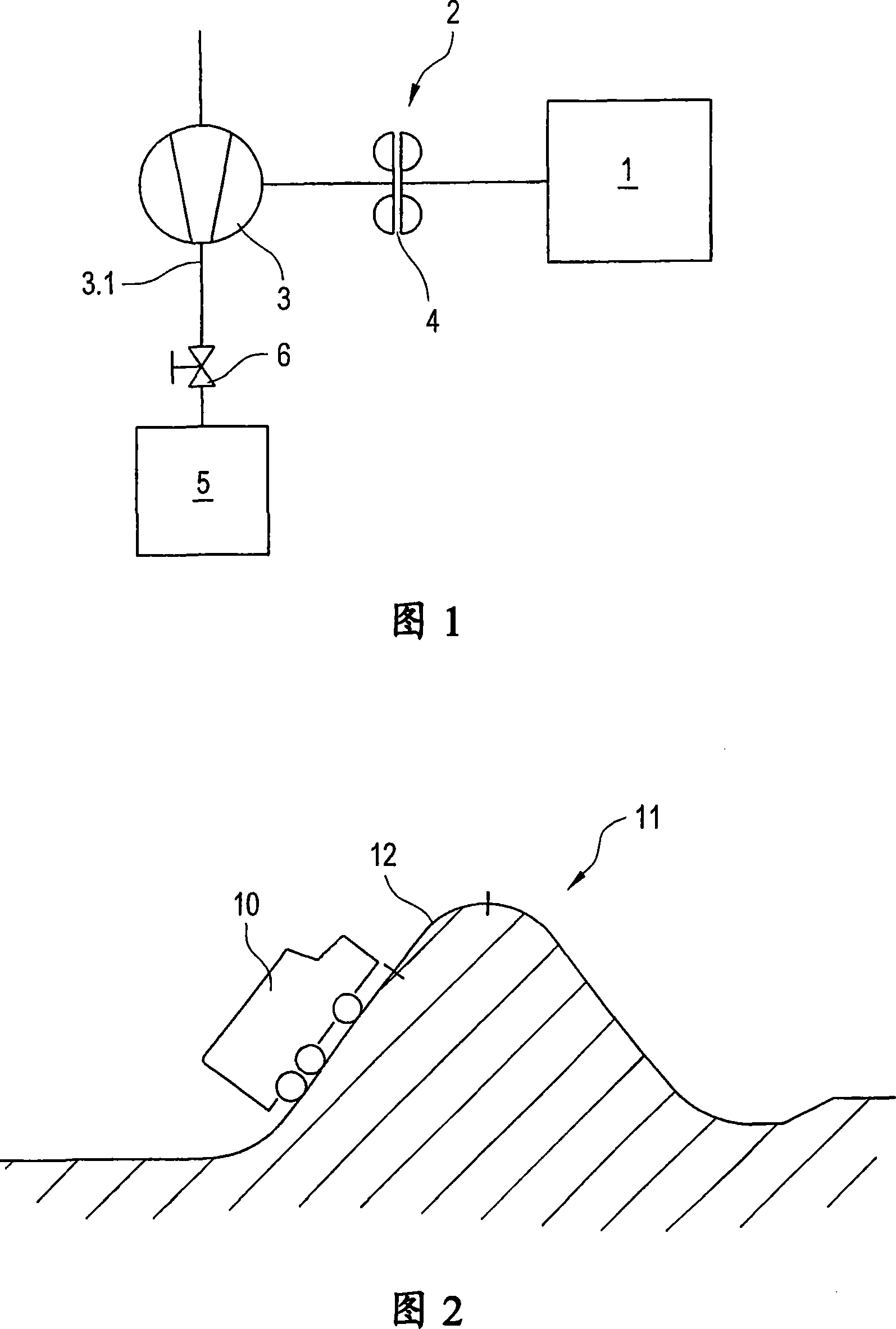

[0021] Fig. 1 shows the driving engine 1 of the motor vehicle, the driving engine is connected to the transmission connecting device connected to the air compressor 3 by filling the hydraulic coupling 4 with the working medium, especially the oil in the engine circulation oil circuit 2 in. When the engine 1 drives the air compressor 3 , that is to say when the method according to the invention is switched to the supply state, the air compressor supplies air to the compressed air system 5 of the motor vehicle via its air output side 3 .

[0022] A switchable and / or adjustable throttle valve 6 is installed in the line for supplying compressed air on the air output side 3.1, ie in the line connecting the air compressor 3 to the compressed air system 5 in an air-conducting manner. . According to an advantageous embodiment of the method according to the invention, when it is desired to transmit as much drive power as possible from the drive engine 1 to the air compressor 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com