High-pressure large load air spring

An air spring, large load technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., to achieve the effect of high strength, large load and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

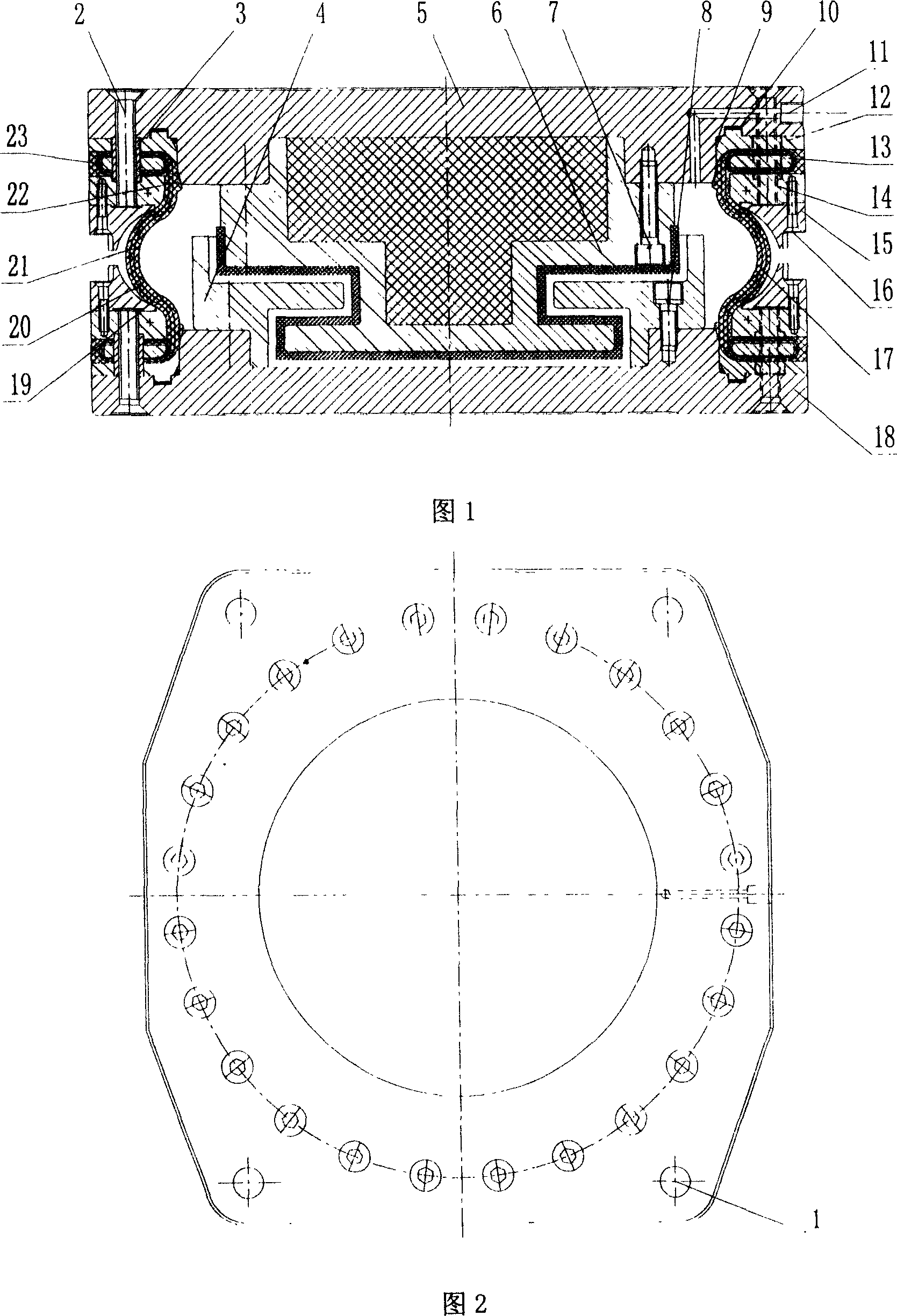

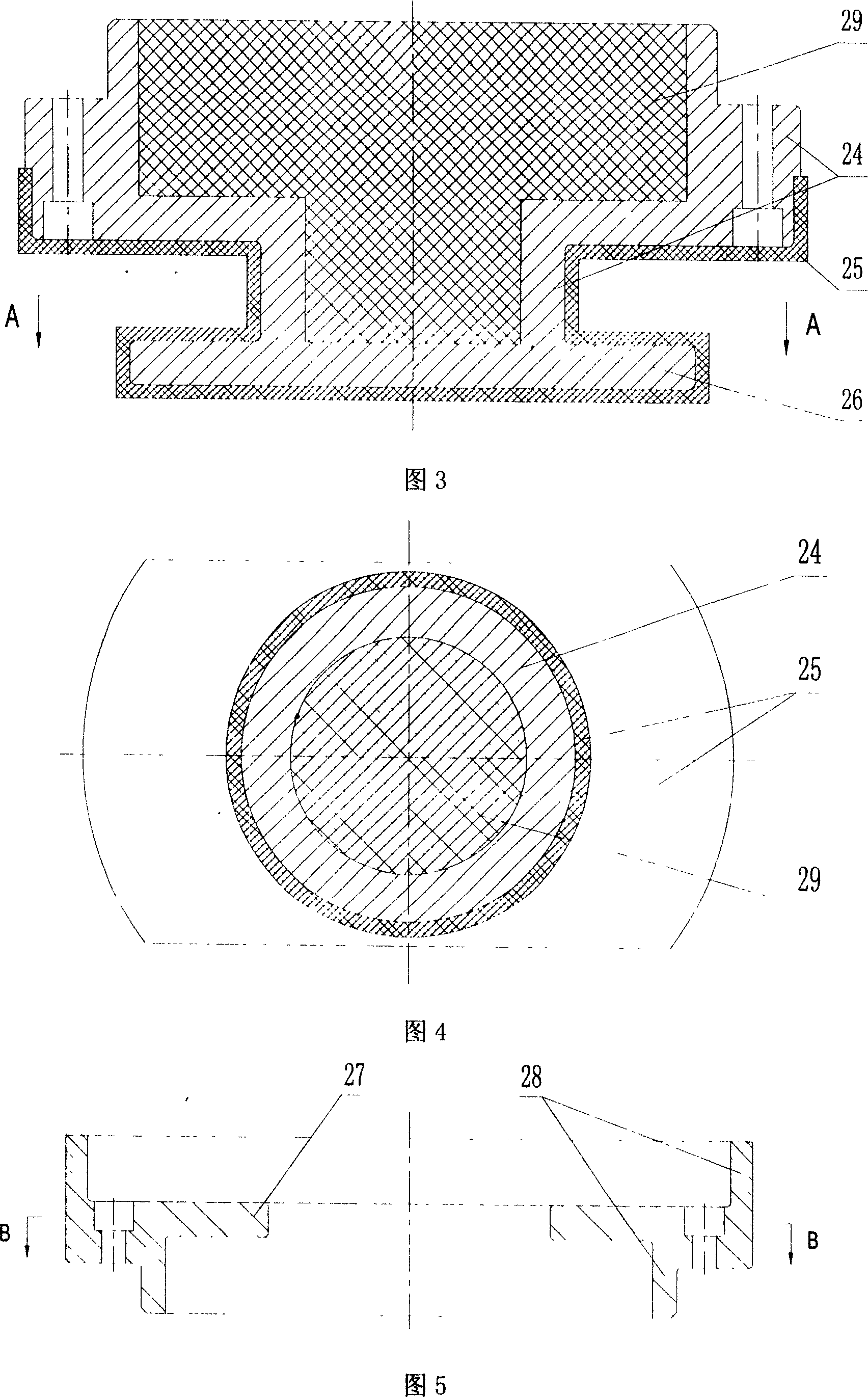

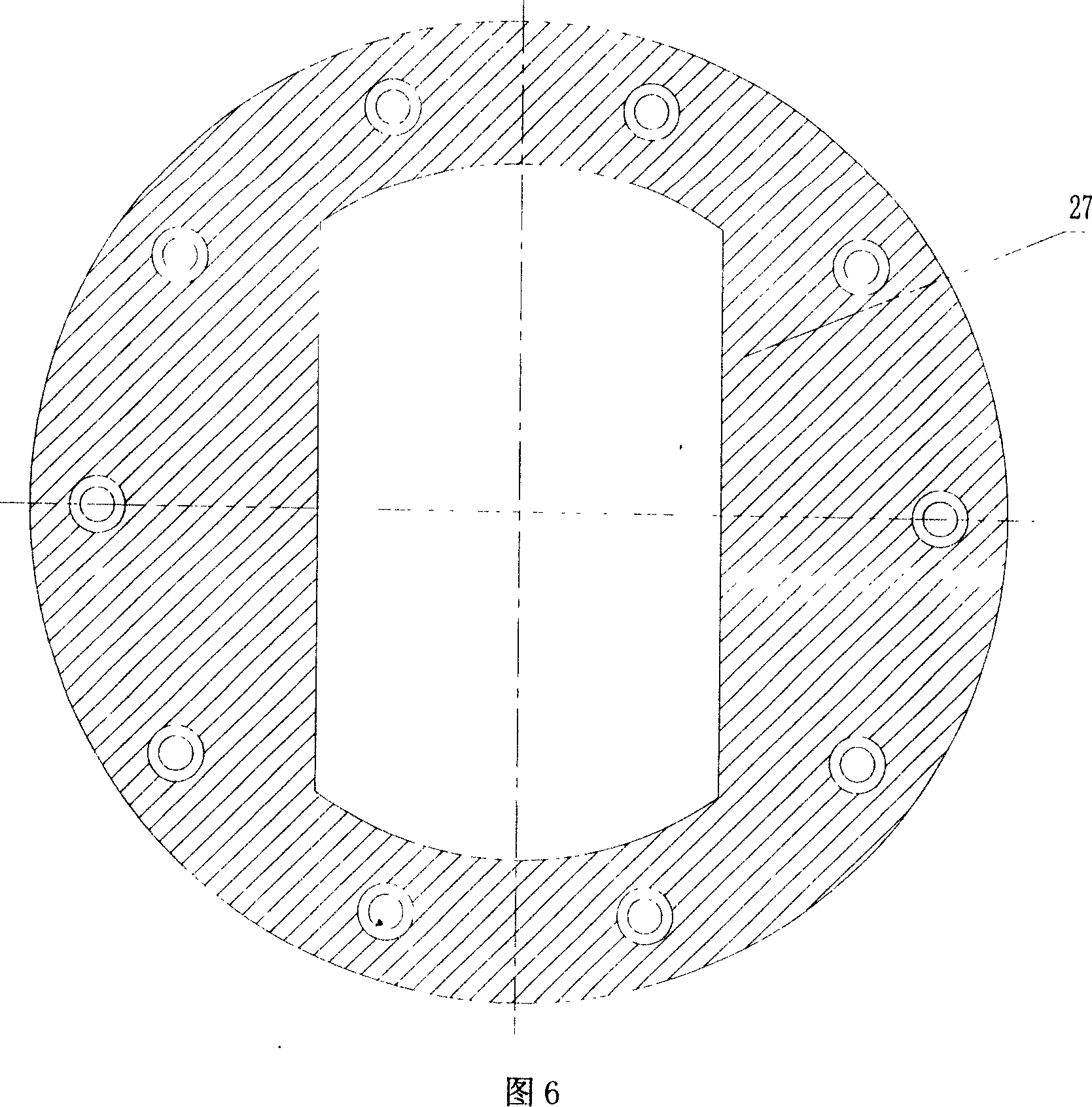

[0014] Referring to Figures 1 and 2, the present invention consists of five parts: a rubber capsule body 17, a disc flange 15, upper and lower cover plates 5, 18, high-performance sealing rings 9, 10, and upper and lower fillers 6, 4 in the rubber capsule body. .

[0015] The rubber capsule body 17 is vulcanized into an integral structure by the inner rubber layer 21, the outer rubber layer 19 and the cord skeleton layer 20. The skeleton layer is made of aramid fiber cord, and its strength is equivalent to that of steel wire, and about three times higher than that of nylon and polyester. Under the condition of the same structural size of the airbag, the rubber bladder body using aramid fiber cord is about three times higher than the rubber bladder body using ordinary nylon, polyester and other cords, and the bearing capacity is also about three times higher, so it can realize high pressure The large load ensures that the internal pressure of the strong vibration isolator reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com