Fixture

A jig and hollow technology, applied in the jig field, can solve the problems of loss of flatness, uneven distribution, workpiece deformation, etc., to avoid deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

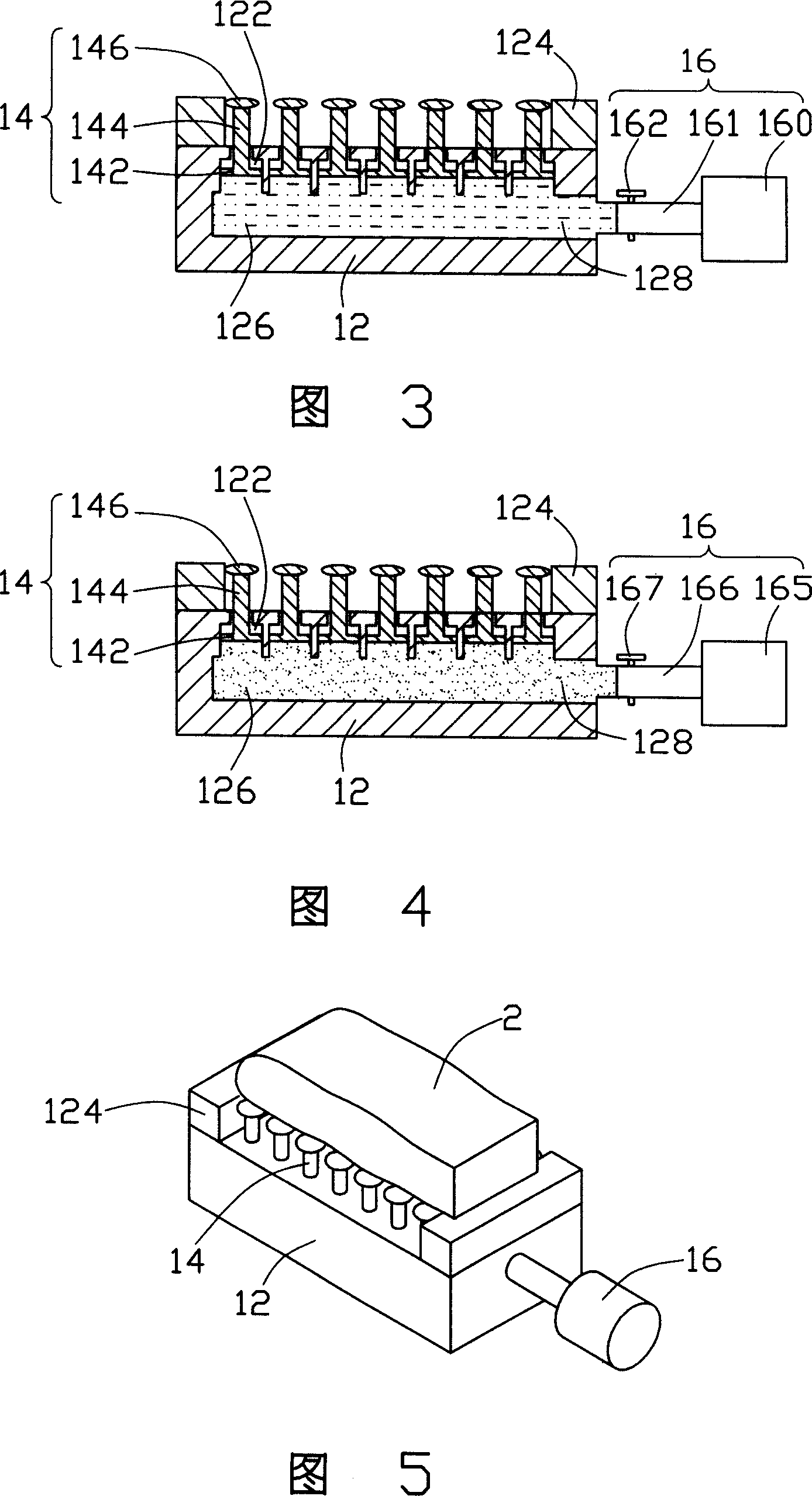

[0014] Referring to FIG. 2 , the jig 1 of the present invention includes a base plate 12 , a plurality of support rods 14 and a pressure control system 16 .

[0015] Please refer to Fig. 3 at the same time, the base plate 12 has a working surface 120 and a hollow cavity 126, two opposite edges on the working surface 120 are respectively provided with two bearing blocks 124, and the working surface 120 is provided with multiple Through holes 122 communicate with the hollow cavity 126. A channel 128 is defined on one side of the substrate 12, and the channel 128 is connected to the hollow cavity 126, so that the hollow cavity 126 can communicate with the outside world. Wherein, the hollow cavity 126 is filled with a flow medium, which can be gas or liquid.

[0016] The support rod 14 includes a piston body 142, a load bearing rod 144 and an arc contact 146. The piston body 142 is accommodated in the through hole 122 and seals the through hole 122; the load bearing rod 144 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com