Substrate integrated waveguide small-sized prism type horn antenna

A substrate-integrated waveguide and horn antenna technology, applied to waveguide horns, antennas, electrical components, etc., can solve problems such as designing horn antennas, and achieve the effects of low return loss, high gain, and easy camouflage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

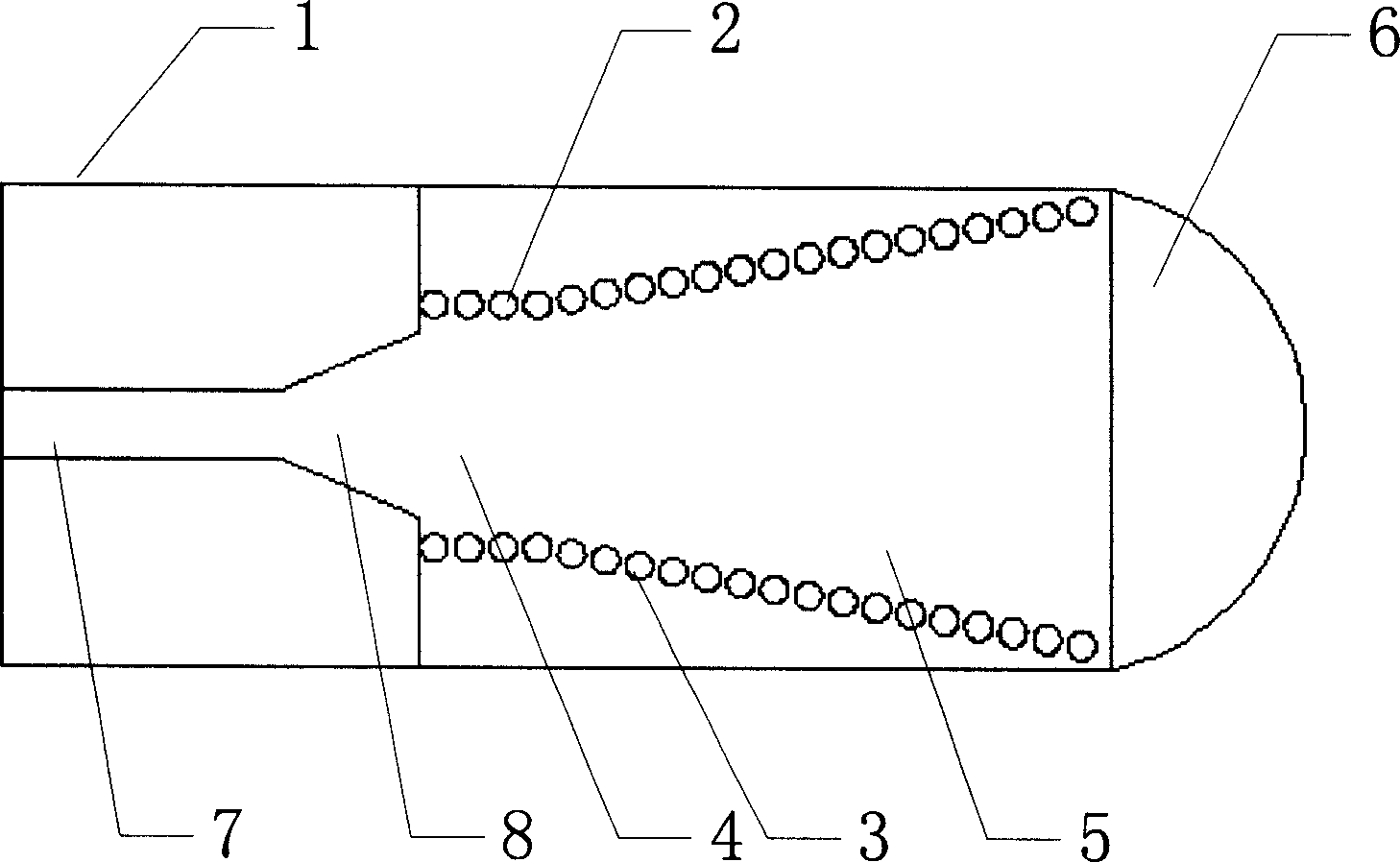

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] In conjunction with the accompanying drawings, the substrate integrated waveguide prism horn antenna of the present invention includes a dielectric substrate 1, the thickness of the dielectric substrate 1 is 2mm, the thickness of the dielectric substrate 1 can be 0.32λ~0.49λ, and the dielectric constant is 10.2. The range of dielectric constant of the dielectric substrate 1 may be 2-15. Two rows of metal pillars 2, 3 are arranged on the dielectric substrate 1, and the two rows of metal pillars 2, 3 respectively form the interconnected substrate-integrated rectangular waveguide 4 and the H-plane horn section 5, and the two rows of metal pillars 2, 3 form a H On the two walls of the opening of the horn section 5, the radius of the metal pillars of the two rows of metal pillars 2 and 3 is 0.4mm, and the distance between two adjacent metal pillars is 1mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com