High-temperature and high-pressure wheeled continuous feeding airlock system

A high-temperature, high-pressure, wheel-type technology, used in rotary conveyors, engine seals, conveyors, etc., can solve problems such as low efficiency, and achieve high work efficiency, less steam leakage, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

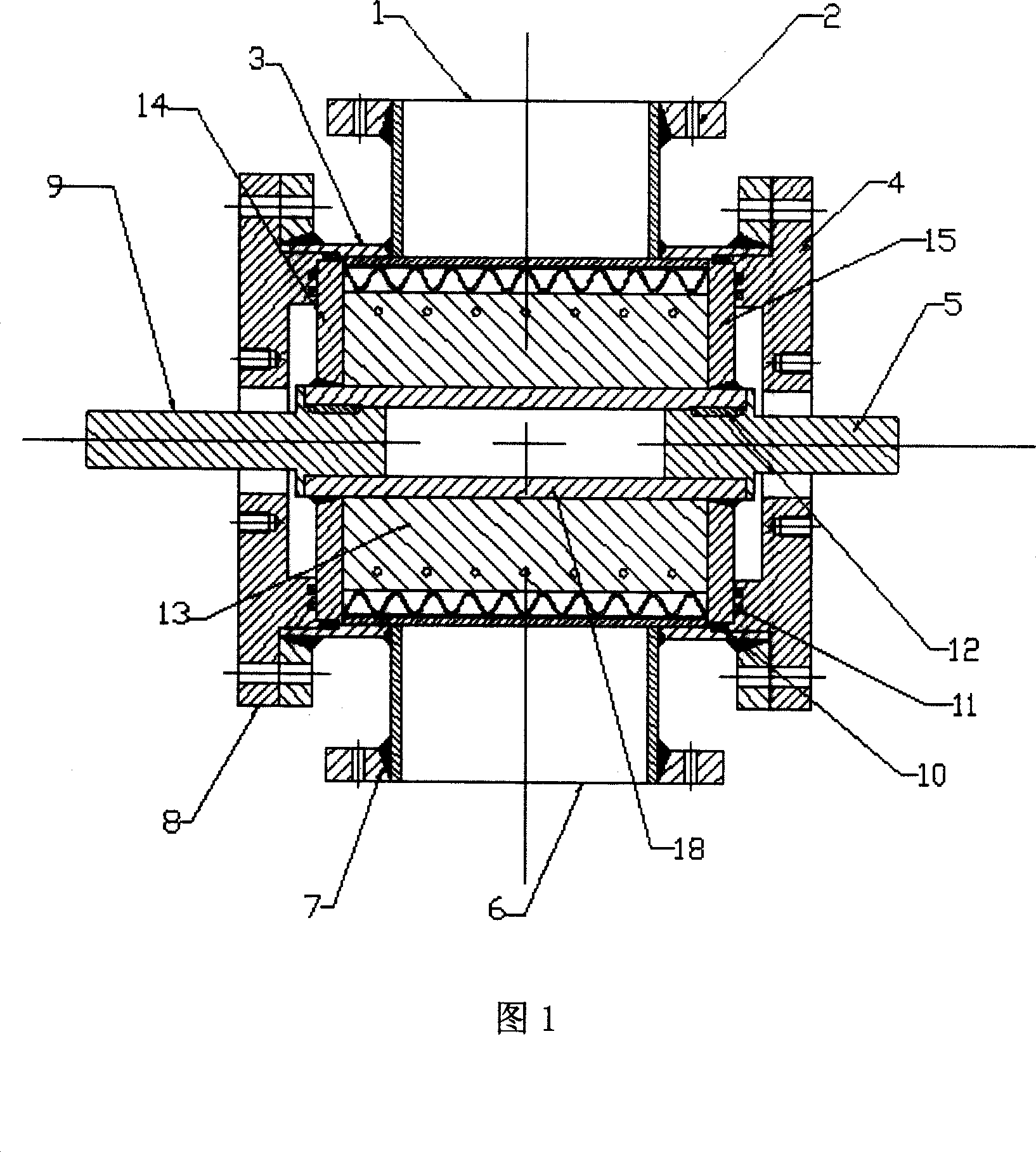

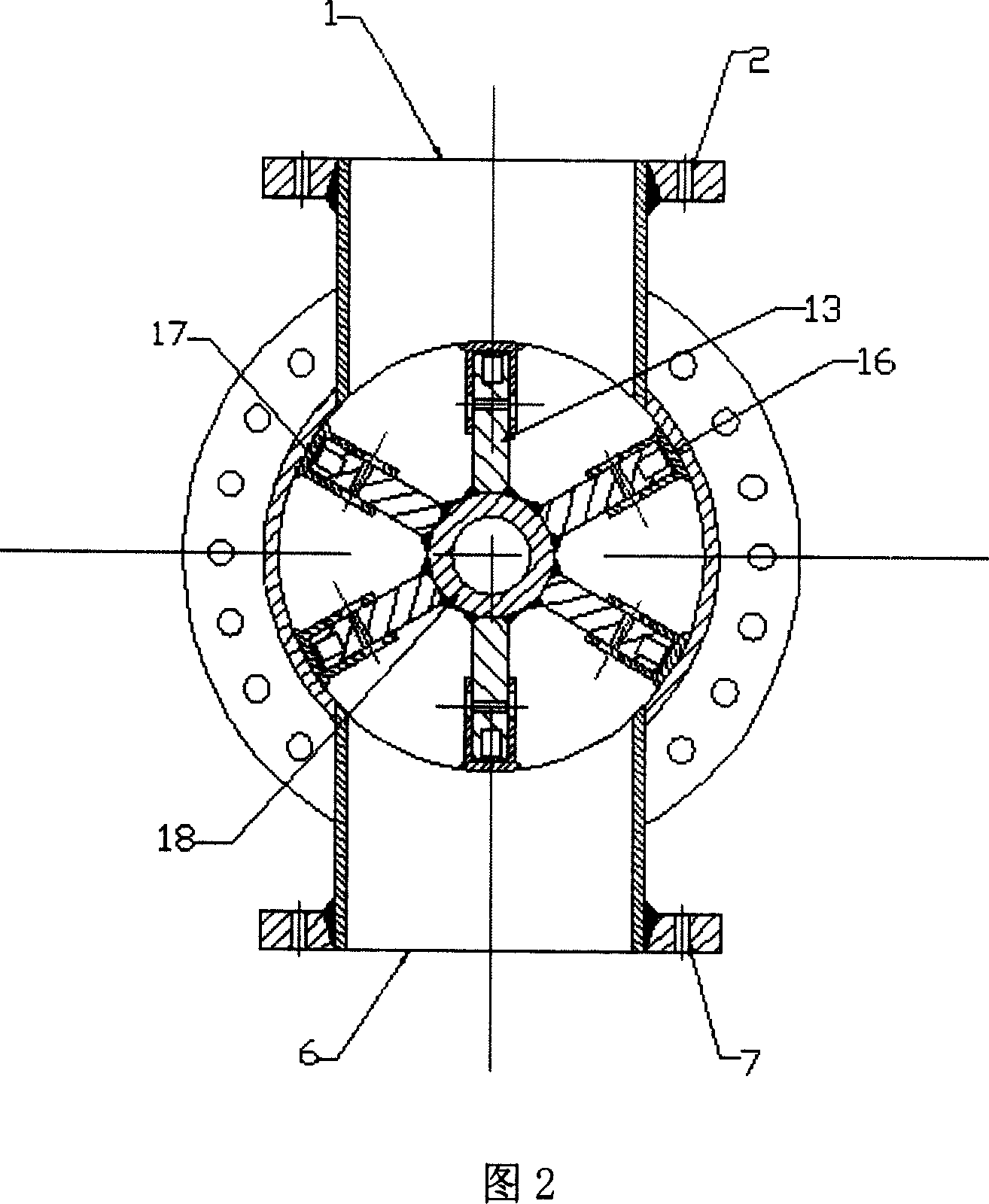

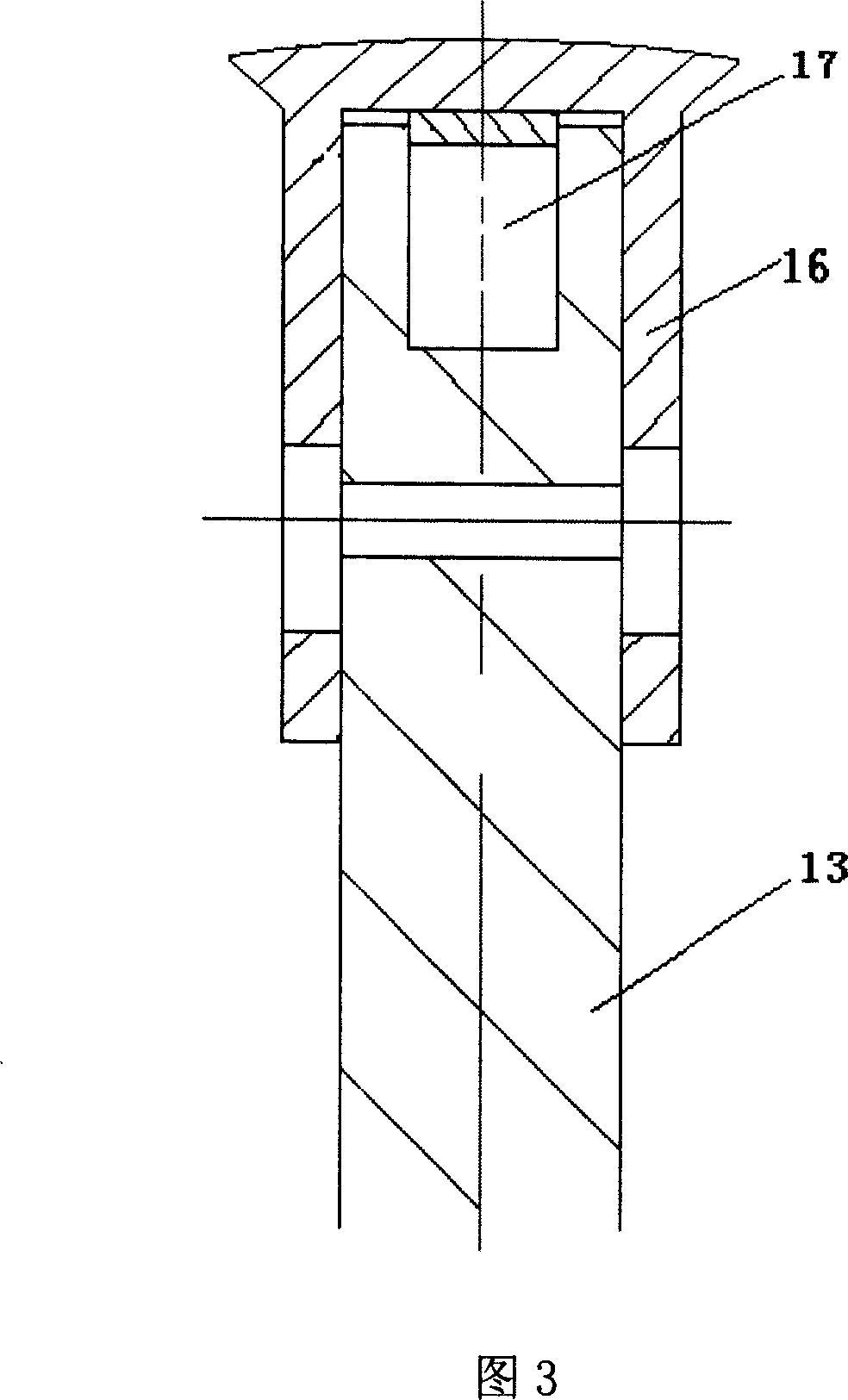

[0015] Referring to the accompanying drawings, the rotary high-temperature and high-pressure continuous feeding airlock system of the present invention includes a casing, which is formed by connecting a cylinder body 3 and two end covers 4, 8 via bolt flanges. The upper part of the cylinder body 3 is provided with a material inlet 1, and the lower part is provided with a material outlet 6, and the material inlet flange 2 and the material outlet flange 7 are respectively welded. A runner is installed in the casing, and the runner is welded on the rotating shaft 18 by the evenly distributed runner 13 and the baffle rings 14, 15 on both sides. The top of the runner 13 is connected with a wide-body friction plate 16, and the rotating shaft 18 The two ends of are provided with bearing head 5,9, and the bearing head 5,9 at rotating shaft 18 two ends links to each other with rotating shaft 18 by key 12.

[0016] The following inventors give the working process of the rotary high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com