Intelligent quick heating water eispenser

A rapid heating and water dispenser technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of not being able to effectively adjust whether the water is out, and the temperature of the water out, so as to avoid the loss of nutrients and avoid Repeated heating, not easy to scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

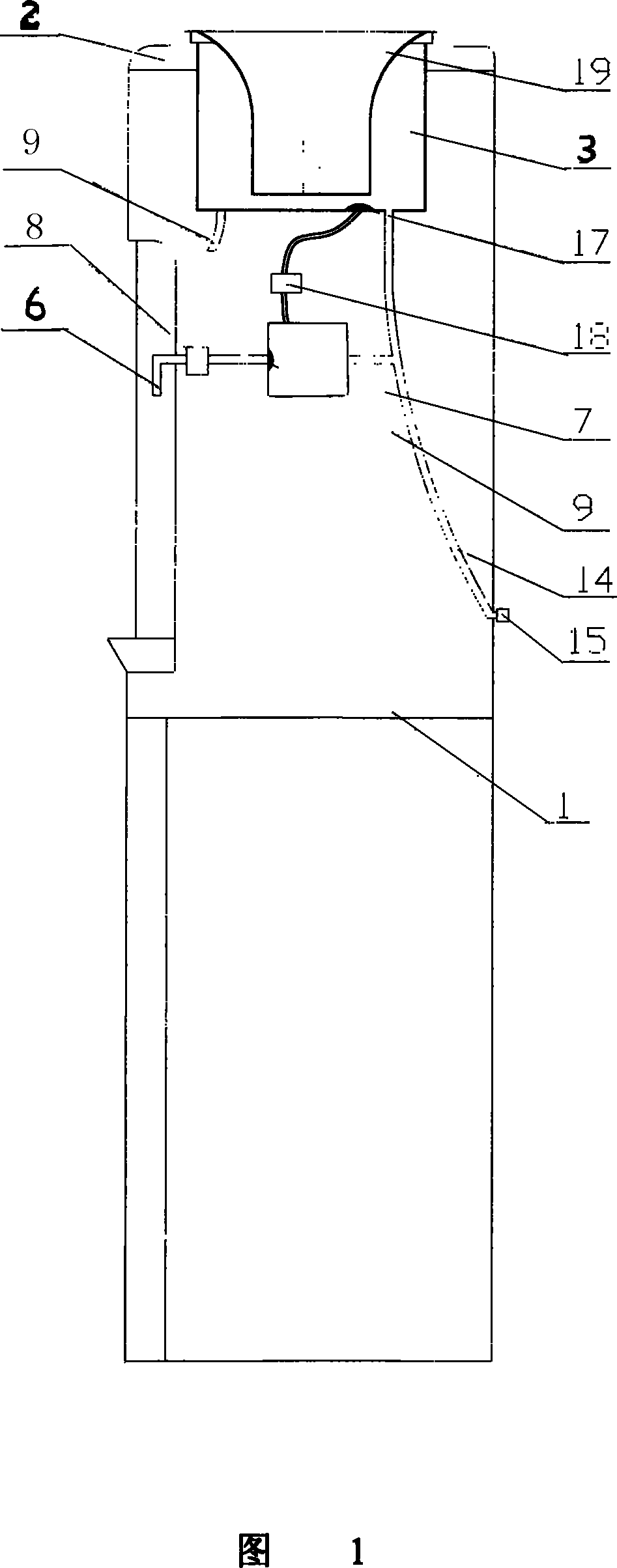

[0029] Referring to Fig. 1, Fig. 2, Fig. 5, Fig. 6 and Fig. 8, an intelligent fast heating water dispenser includes a housing 1, a bottle holder 2, a bucket 3 on the bottle holder 2, a power switch 4 and a cold water outlet 5 1. The hot water outlet 6 and the cold water outlet 5 are connected to the water bucket 3 through the cold water pipe. The water bucket 3 is provided with a smart core, and a cold water valve is installed on the cold water pipe. The fast heater 7 that needs temperature, the water inlet of the fast heater 7 communicates with the water bucket 6, the water outlet of the fast heater 7 communicates with the hot water outlet 6 through the hot water solenoid valve 8, and the electric heating tube of the fast heater 7 passes through the power supply The switch 4 is connected to an external power supply, and the power switch 4 is set on the hot water outlet 6; the fast heater 7 is an electrothermal film heater, and the electrothermal film heater includes an electro...

Embodiment 2

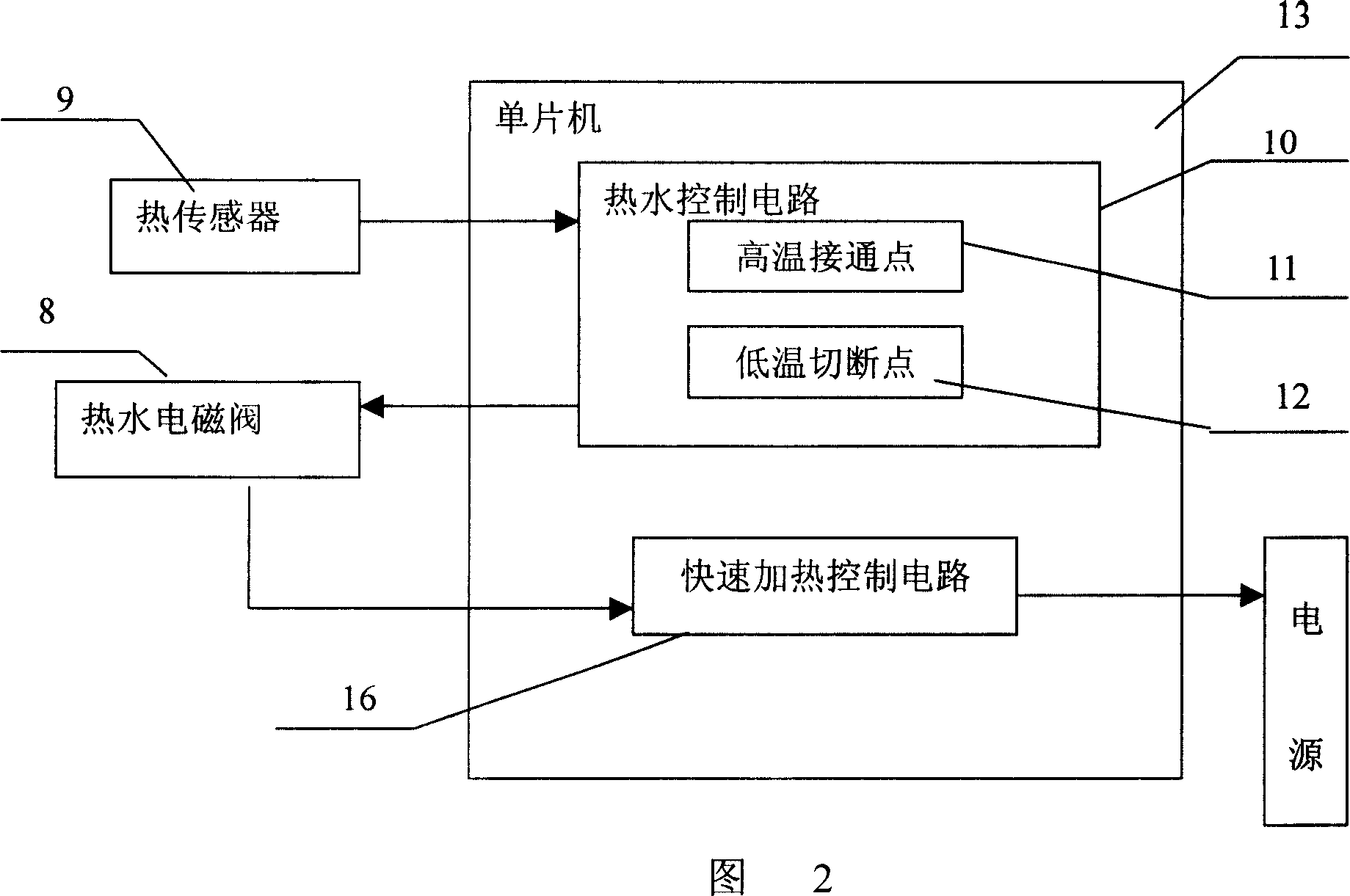

[0033] With reference to Fig. 1, Fig. 2, Fig. 5, Fig. 6, Fig. 8, the external power supply described in this embodiment is a power supply with adjustable power; the casing 1 also includes a maximum power of the electric heating tube ( 2000w) operation, when the hot water electromagnetic valve is turned on, the rapid heating control circuit 16 operates according to the preset power (1500w). The input end of the rapid heating control circuit 16 is electrically connected to the electromagnetic valve 8, and the rapid heating control circuit 16 The output end is connected with the power supply. The fast heating control circuit 16 is also integrated on the single-chip microcomputer 13 .

[0034] Turn on the power switch 1, the electric heating tube runs at the maximum power (2000w), and quickly heats the cold water. When the temperature reaches the required temperature (95°C), the high temperature connection point 11 of the hot water control circuit sends a signal to the hot water sol...

Embodiment 3

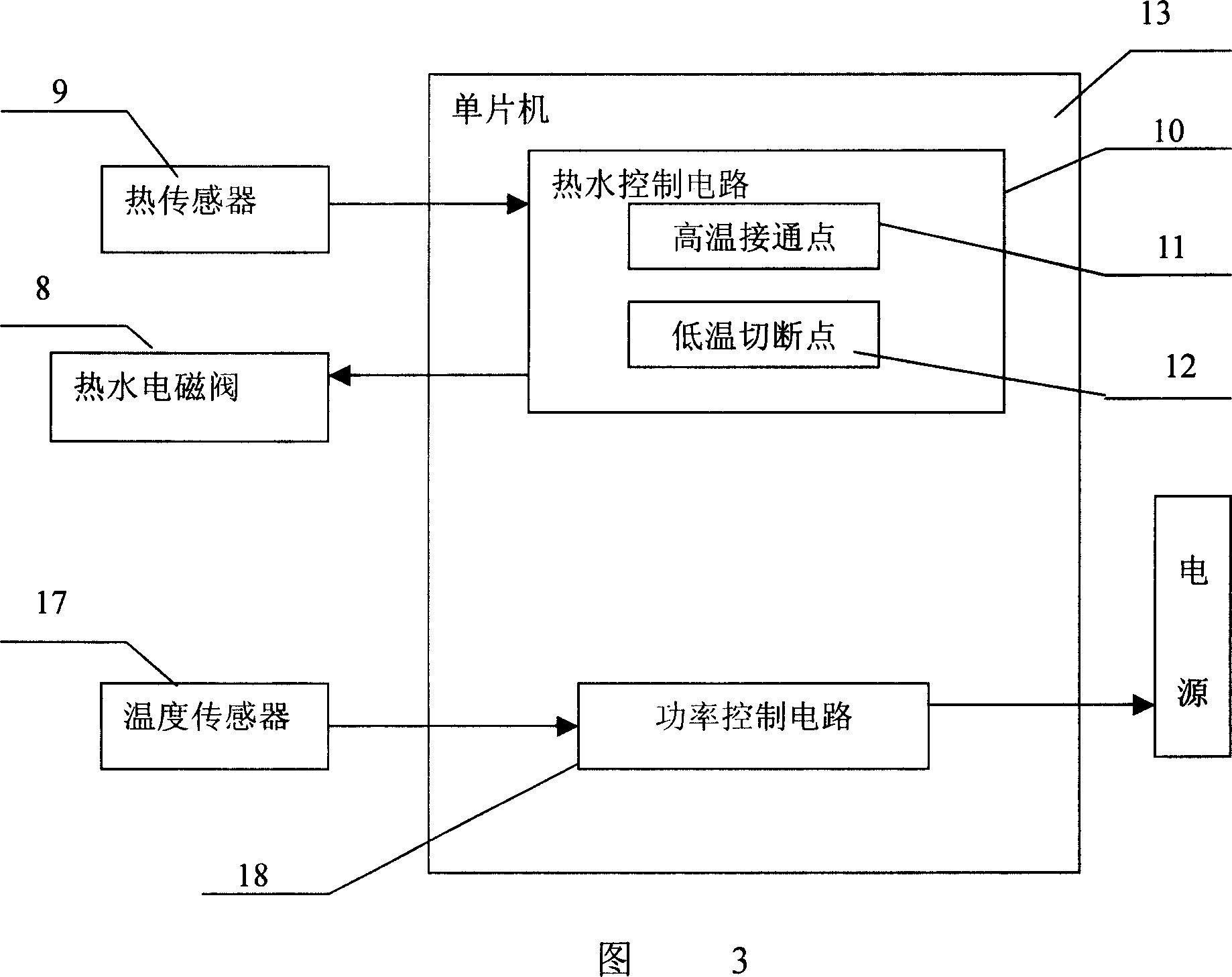

[0037] Referring to Fig. 1, Fig. 3, Fig. 5, Fig. 7 and Fig. 8, a temperature sensor 17 is provided on the bucket 3 of the present embodiment, and the external power supply is a power supply with adjustable power; The power control circuit 18 that controls the preset power of the electric heating tube according to the temperature of the temperature sensor, the temperature sensor 17 is electrically connected to the input end of the power control circuit 18; the output end of the power control circuit 19 is connected to the power supply. The power control circuit 18 is also integrated on the single chip microcomputer 13 .

[0038] serial number

Bucket water temperature (℃)

Electric heating tube preset power (W)

1

5~9

1800

2

10~14

1700

3

15~19

1600

4

20~24

1500

5

25~29

1400

6

30~34

1300

7

over 35

1200

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com