Member for online cleaning and removing scale of heat exchange tube

A technology for heat exchange tubes and components, applied in the field of on-line cleaning and descaling of heat exchange tubes, can solve problems such as unsatisfactory cleaning and descaling effects, difficult wet diameter and specific gravity of rubber balls, and large flow resistance, etc. The effect of controllable and stable density and low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

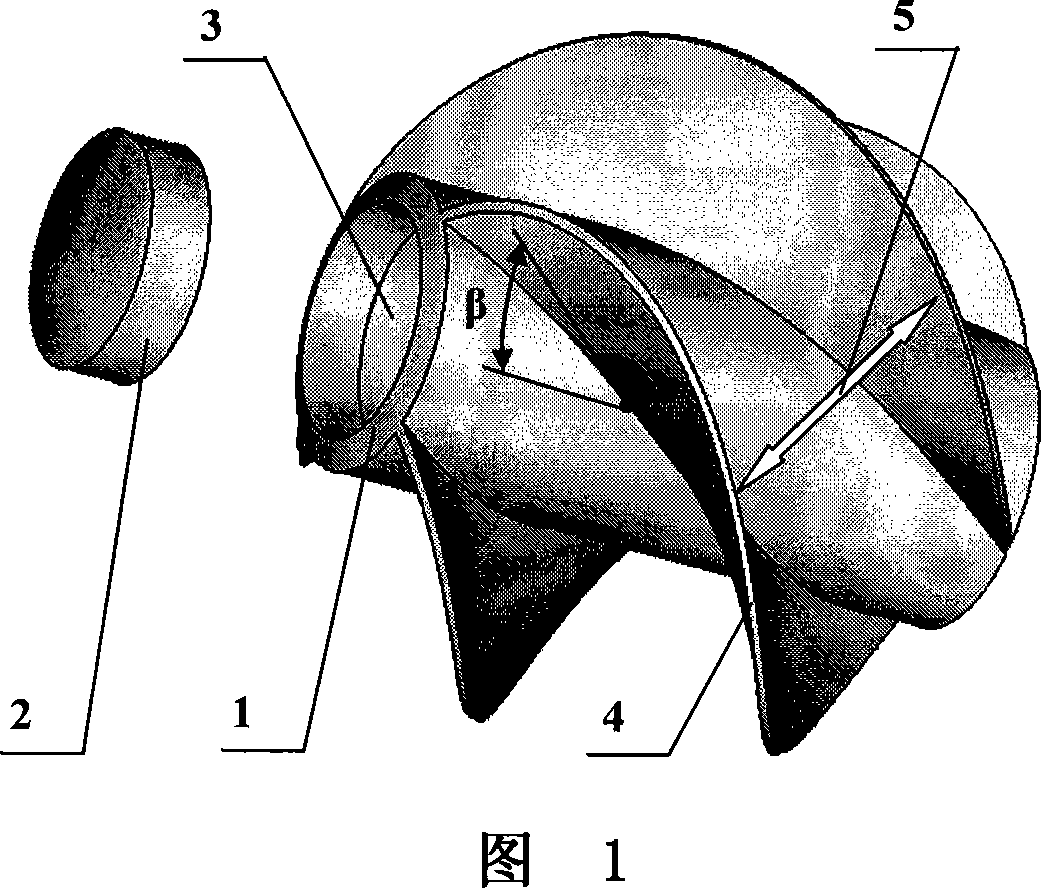

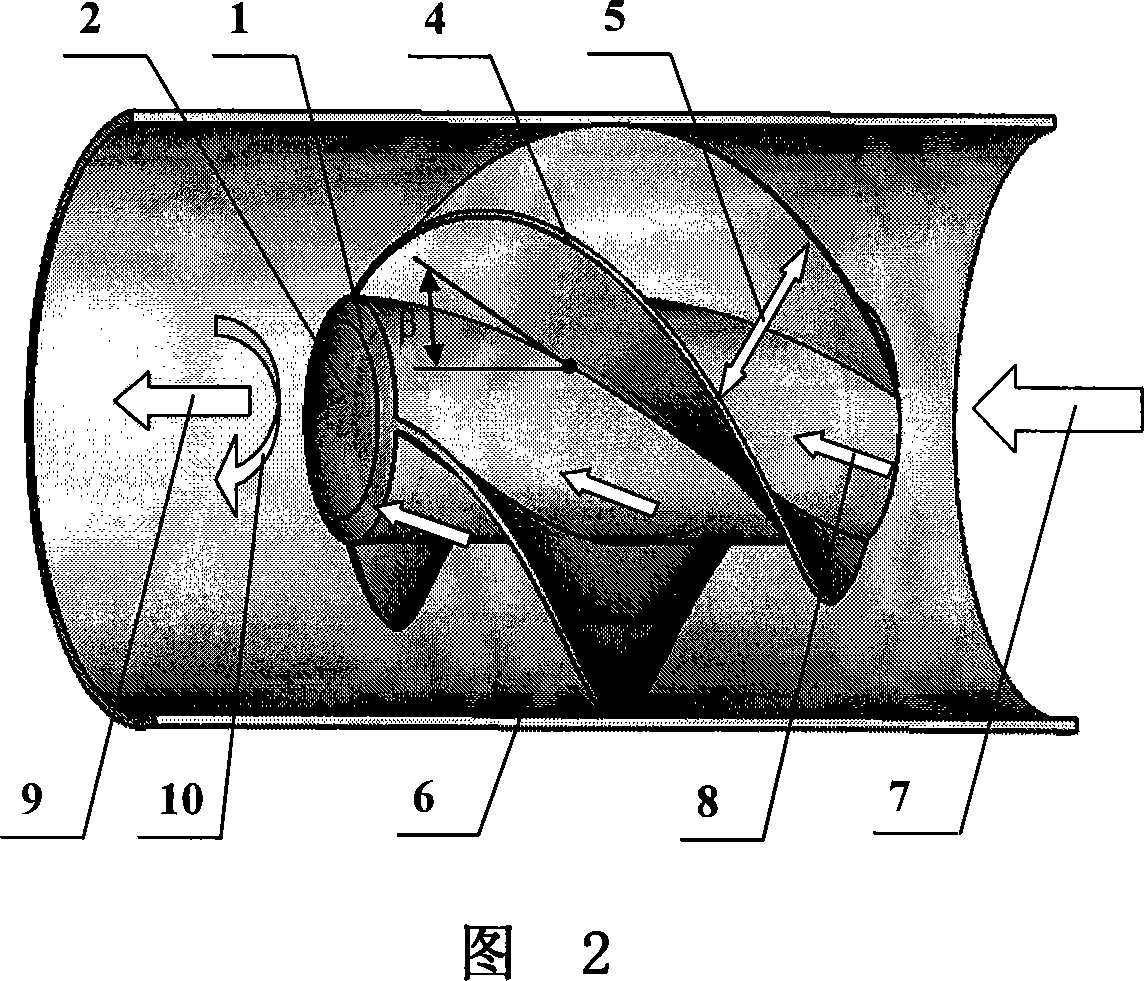

[0036] As shown in Figure 1, the present invention includes a hollow cylindrical density adjustment cavity 1, one end of the adjustment cavity 1 is closed, and the other end is sealed and connected to an end cover 2, and the connection between the end cover 2 and the adjustment cavity 1 can adopt an interference fit , can also be glued, and can also be connected by a barb connection or the like. An adjustment medium 3 is arranged in the cavity of the adjustment cavity 1, and four helical blades 4 are evenly arranged on the outer circumference of the adjustment cavity 1 with the axis of the adjustment cavity 1 as the axis of rotation. The helix angle of the helical blades 4 is β, four Each helical blade 4 and the largest outer contour of the regulating cavity 1 jointly form an approximately spherical spherical element, and the space between each helical blade 4 forms four helical flow channels 5 .

[0037] In this embodiment, the material for the helical blade 4 and the regulat...

Embodiment 2

[0045] As shown in Figure 9, the difference between this embodiment and Embodiment 1 is: the axis of rotation is a solid cylinder 17, that is, the axis of the solid cylinder 17 is the axis of rotation of the spherical cleaning and descaling element, and in the solid cylinder 17 Four helical blades 18 are uniformly arranged in the circumferential direction of the helical blade 18, and the helix angle β of the helical blades 18 is 60°, and the maximum outer contour of the four helical blades and the solid cylinder 17 is a spherical spherical element; four helical blades are formed between the four helical blades. A helical space is a helical fluid channel, and when the fluid flows through the helical channel, the spherical element of the present invention will be rotated rapidly. The main body material of this embodiment is non-foam rubber—butadiene rubber+styrene butadiene rubber. In order to improve or change the properties of rubber products (such as strength, density, wear r...

Embodiment 3

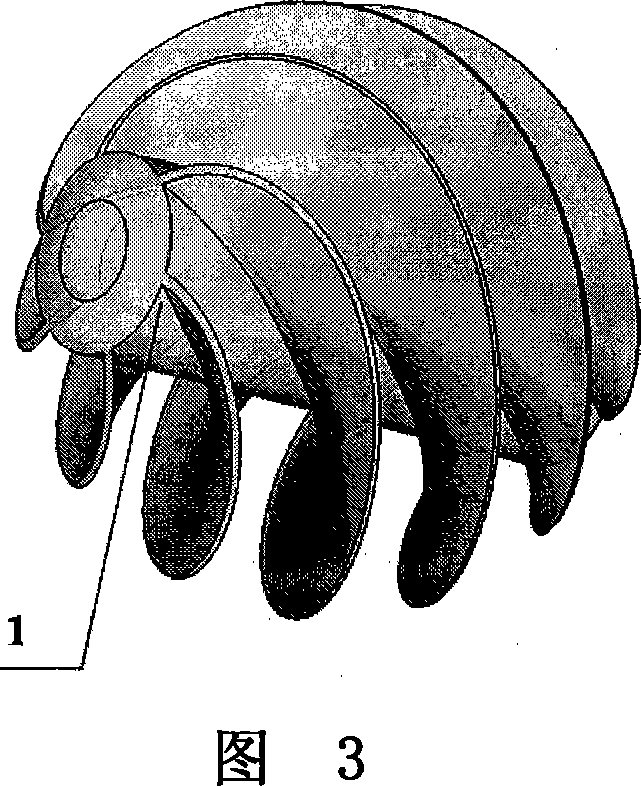

[0047] As shown in Figure 10, the present invention is formed by connecting four helical blades 19, and its connection mode is one-time molding or bonding, and the helix angle β of the helical blades is 45 °, and the maximum outer profile that four helical blades 19 form is Spherical spherical element, four helical blades 19 are evenly arranged in the circumferential direction. In this embodiment, the rotational axis of the spherical element is the symmetrical centerline of the four helical blades, and four helical spaces, namely the helical fluid, are formed between the four helical blades 19. channel, when the fluid flows through the spiral flow channel, the spherical cleaning and descaling element will be rotated rapidly. In this embodiment, no density adjustment cavity is provided, and its density is determined by the density of the material. Appropriate materials can be selected to ensure that its density is relatively close to the density of the transported fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com