Square double mode self-calibration sensor and image rebuilding method based on sensor thereof

A sensor and self-calibration technology, which is applied in image enhancement, image data processing, image data processing, etc., can solve the problem that the simultaneous measurement of virtual and real part information cannot be realized, the sensor does not have calculable uniformly distributed measured values, and does not have self-calibration, etc. Problems, to achieve the effect of expanding the measurement range and measurement accuracy and response speed, widening the measurement range, designing and realizing simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The dual-mode electrical imaging system sensor and the image reconstruction method based on the sensor of the present invention will be described with reference to the drawings and embodiments.

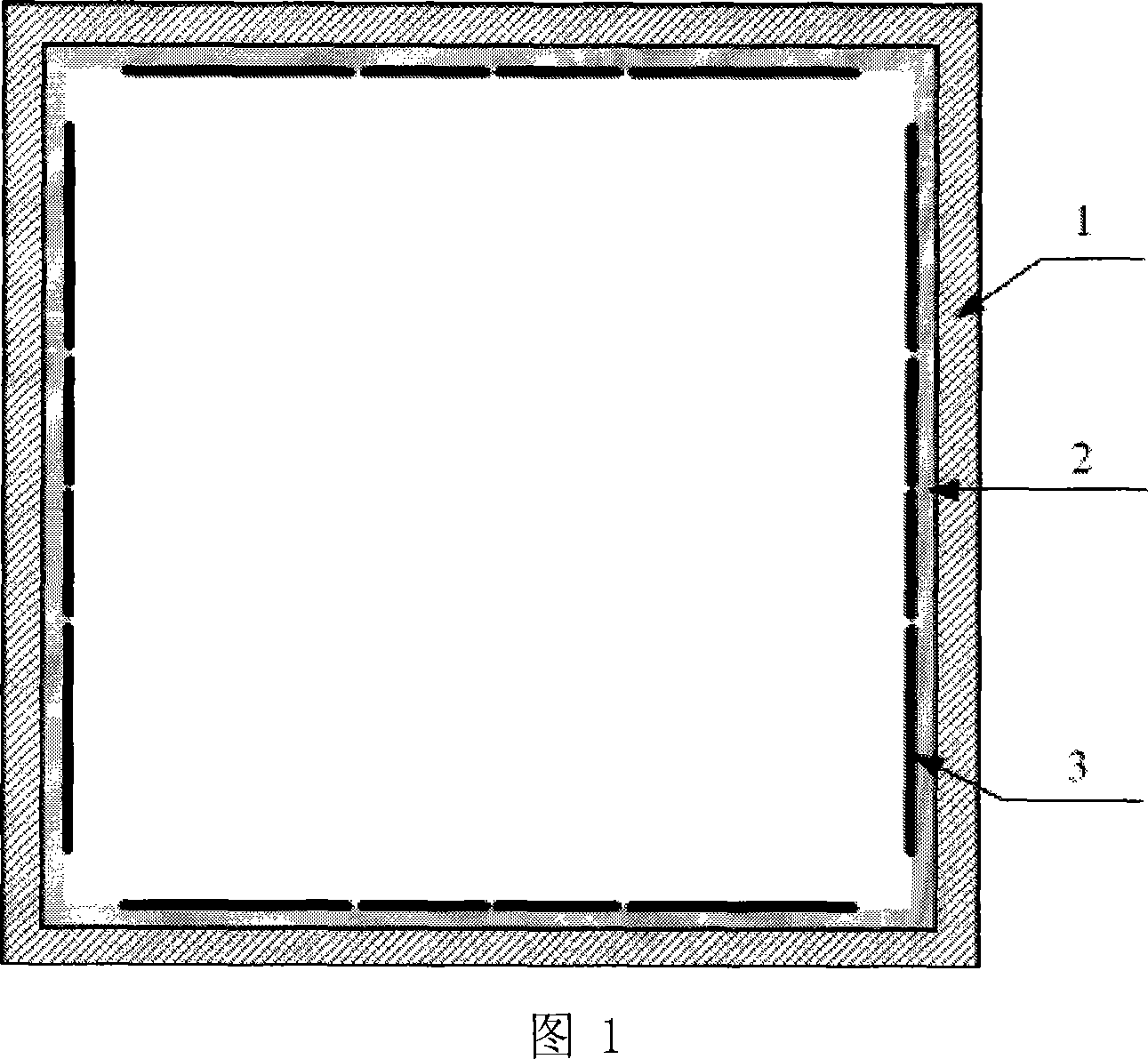

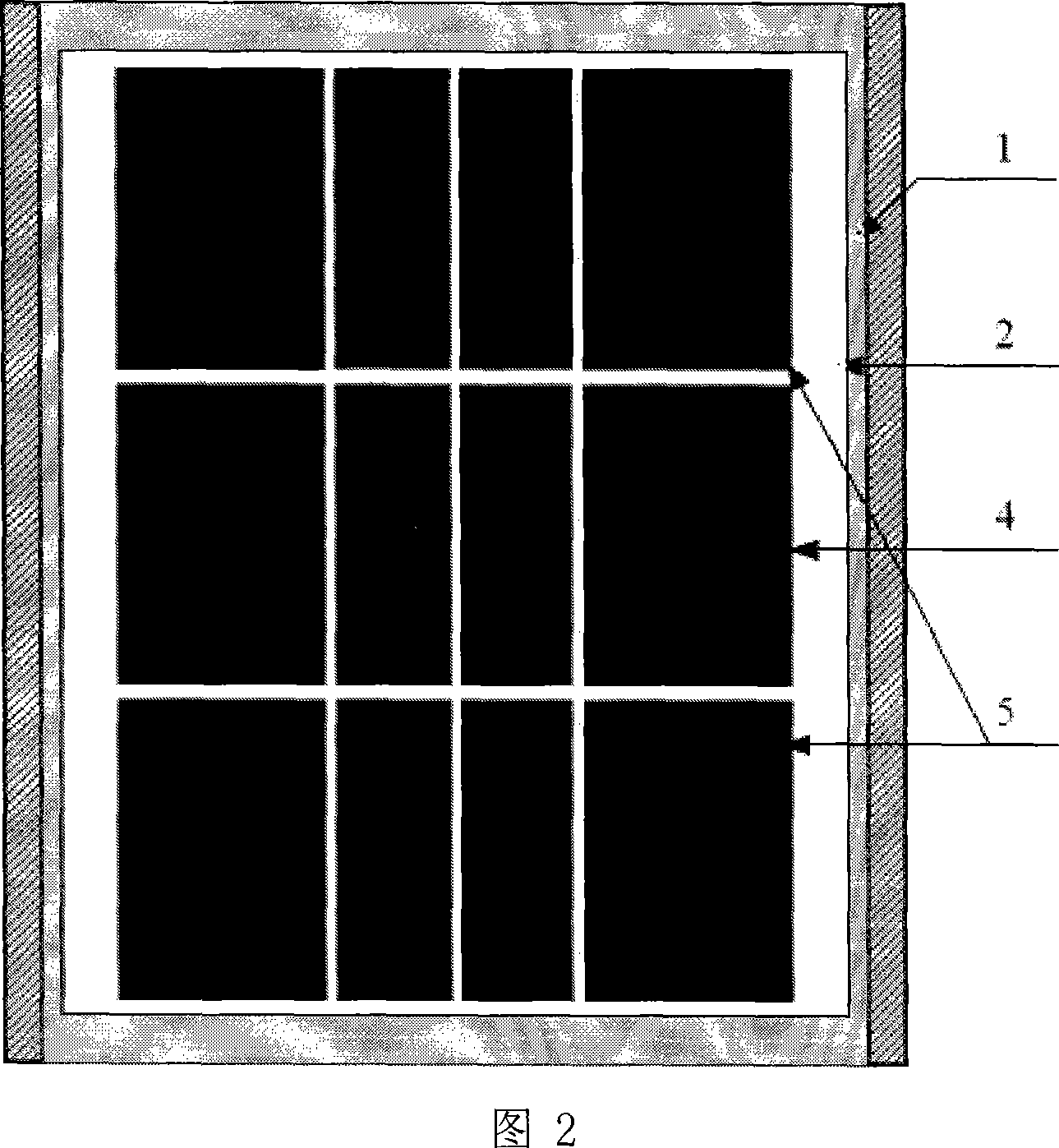

[0025] As shown in Figures 1 and 2, in the cross-section of the dual-mode electrical imaging system sensor, its structure is composed of three layers, the outer layer structure is a metal tube layer 1, which plays the role of structural fixation and shielding, and the middle layer structure is a thin insulating layer. Material layer 2, whose thickness is less than 3% of the electrode size, and ensures that the electric field strength between the electrode and the metal tube layer 1 is smaller than the breakdown strength of the insulating material layer 2, and the inner layer structure layer 3 is a multilayer attached to the insulating layer 2. The electrodes are distributed on the same section according to a certain rule, the position and size of the electrodes are obtained by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com