Touch screen

A touch screen and touch technology, which is applied in the field of touch screen, can solve the problems of flickering display screen, long time occupation, and lower reliability, so as to achieve the effect of improving reliability, improving precision, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

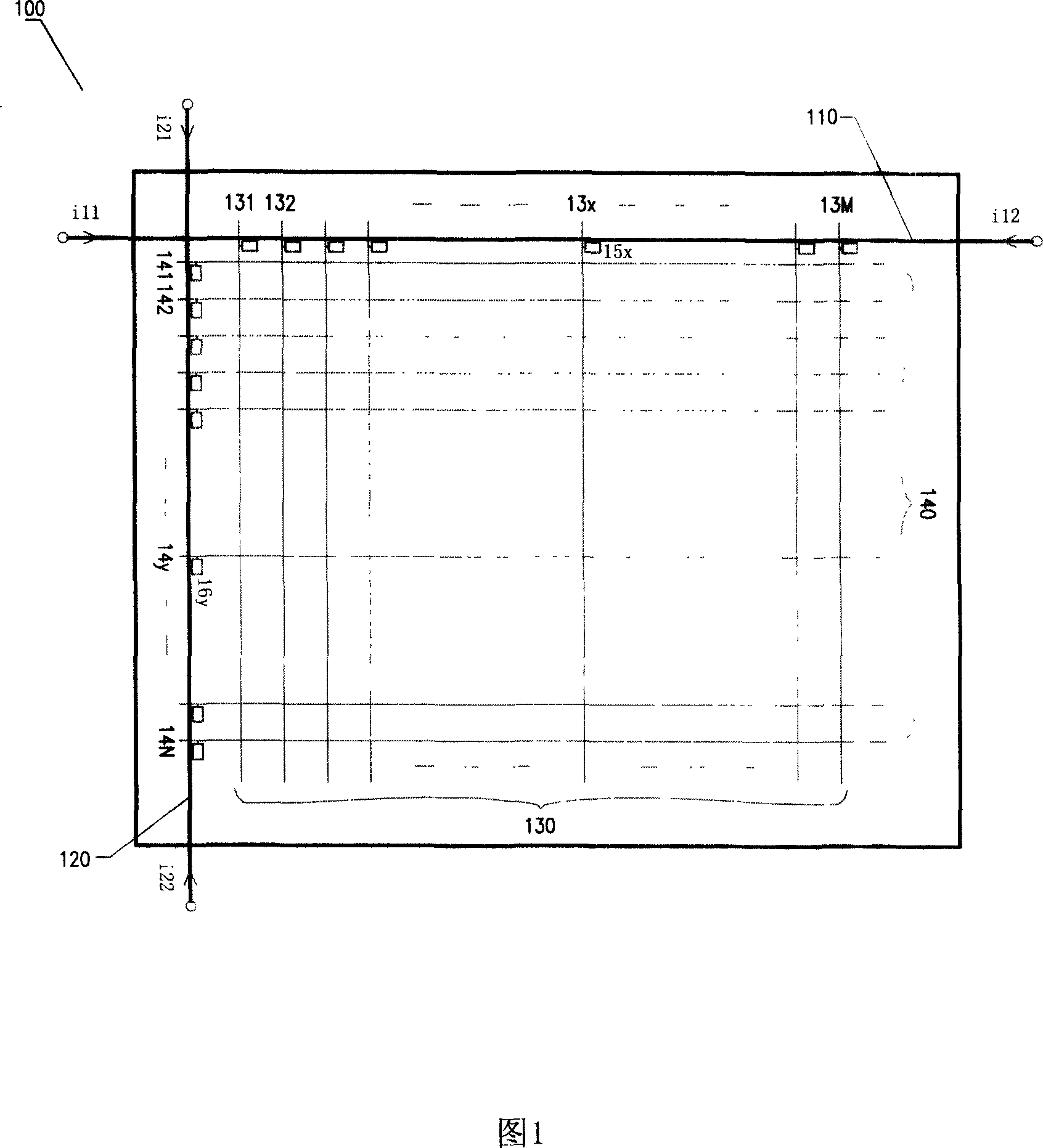

[0041] The touch screen 100 shown in FIG. 1 includes a first touch detection electrode line 110 and a second touch detection electrode line 120 with AC bulk resistance, and a first sensing electrode group 130 insulated from each other on different layers. and the second sensing electrode group 140 . The first sensing electrode group 130 includes M sensing electrode lines parallel to each other, which are sensing electrode lines 131, 132, . . . , 13x (2<x<M), . The sensing electrode group 140 includes N sensing electrode lines parallel to each other, which are sensing electrode lines 141, 142, . . . , 14y (2<y<N), . . . , 14N. The measuring electrode lines perpendicularly intersect the sensing electrode lines in the second sensing electrode group 140 respectively. The first touch detection electrode line 110 intersects with the first sensing electrode group 130, the second touch detection electrode line 120 intersects with the second sensing electrode group 140, and the touch ...

specific Embodiment approach 2

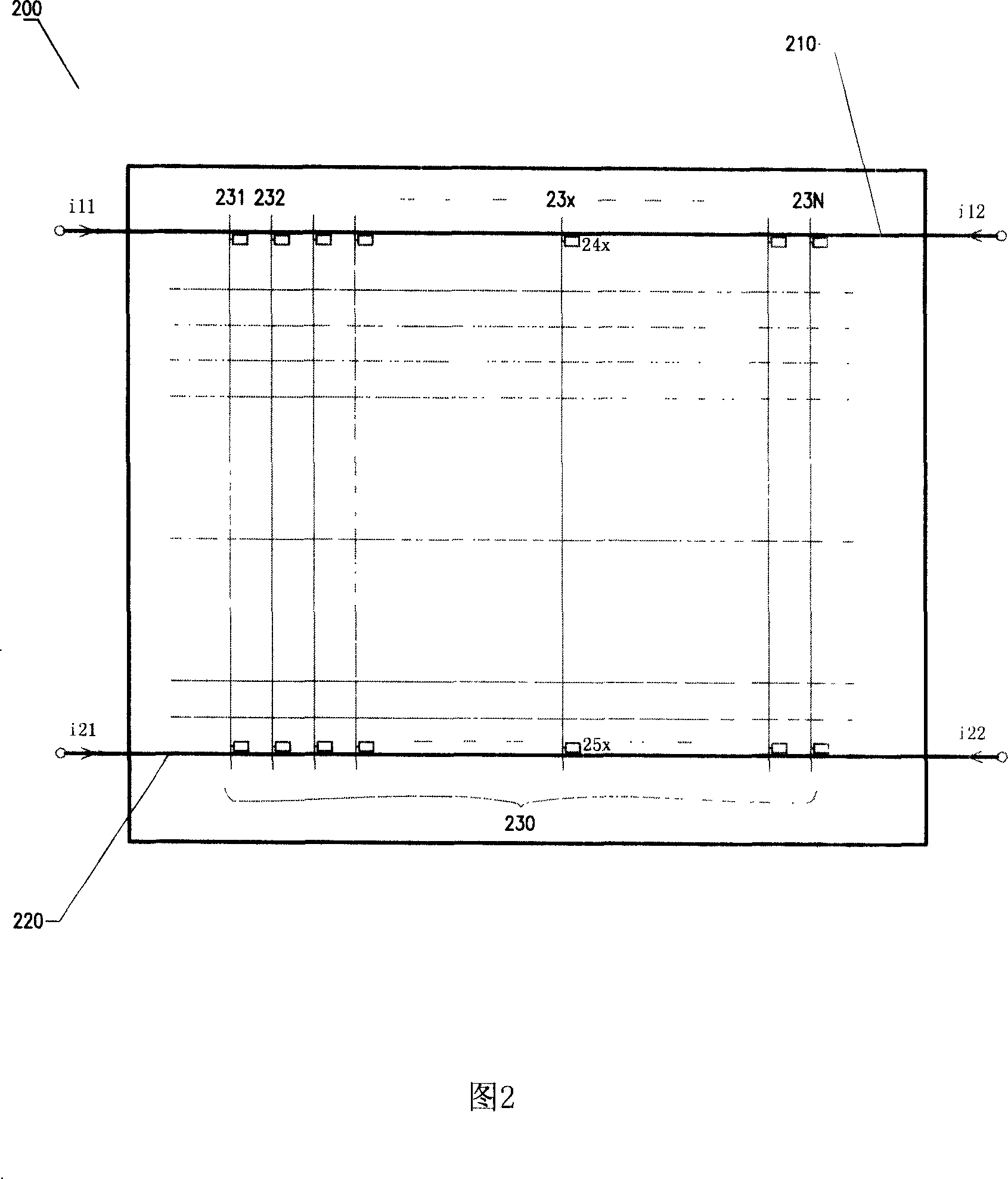

[0045] The touch screen 200 shown in FIG. 2 includes a first touch detection electrode line 210 and a second touch detection electrode line 220 with AC volume resistance, and a sensing electrode group 230 with AC volume resistance. The sensing electrode group 230 includes N sensing electrode lines, which are sensing electrode lines 231, 232, . . . , 23x (2<x<N), . The two touch detection electrode lines 220 intersect with the sensing electrode group 230, and the positions where the first touch detection electrode line 210 and the second touch detection electrode line 220 intersect with the sensing electrode group 230 are respectively biased toward the two sides of the sensing electrode group. end. The touch detection electrode lines and each sensing electrode line of the sensing electrode group are respectively coupled with at least one passive device or active device among capacitance, inductance, and resistance to transmit touch signals. The adjacent coupling points of the ...

specific Embodiment approach 3

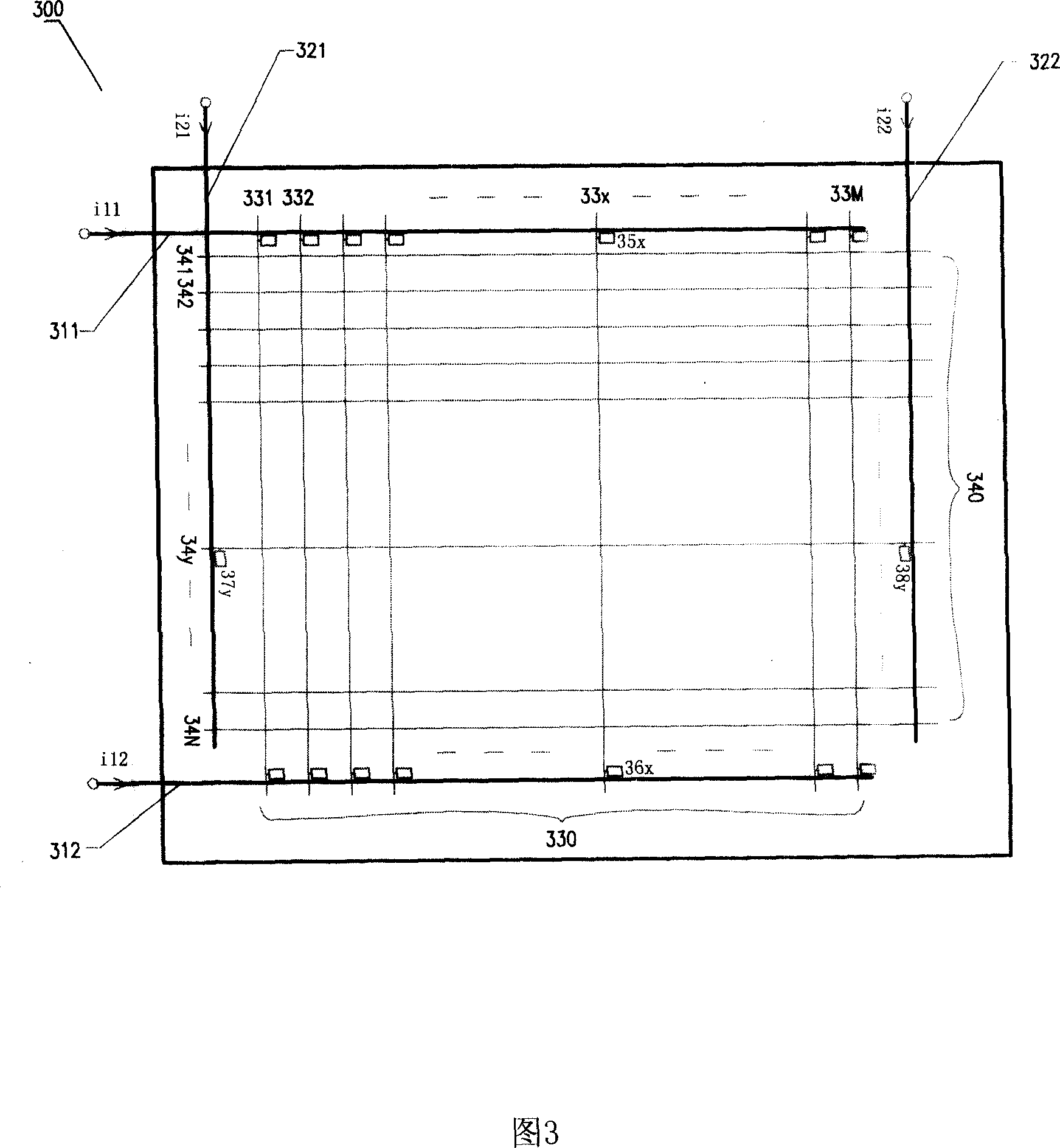

[0049] The touch screen 300 shown in FIG. 3 includes a first touch detection electrode group on different layers, a second touch detection electrode group, and a first sensor on different layers that are insulated from each other and have an AC bulk resistance. The measuring electrode set 330 and the second sensing electrode set 340. The first touch detection electrode group includes a first touch detection electrode line 311, a second touch detection electrode line 312, and the second touch detection electrode group includes a third touch detection electrode line 321, a fourth touch detection electrode line control detection electrode lines 322, the first sensing electrode group 330 has M sensing electrode lines 331, 332, ..., 33x (2<x<M), ..., 33M, and the second sensing electrode group 340 has N Electrode lines 341, 342, . . . , 34y (2<y<N), . . . , 34N. The first touch detection electrode line 311, the second touch detection electrode line 312 intersect with the first sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com