Method for adjusting the rotational angle position of the camshaft of a reciprocating internal combustion engine in relation to the crankshaft

A technology for adjusting pistons and camshafts, applied in valve devices, mechanical equipment, engine components, etc., can solve problems such as non-existence, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

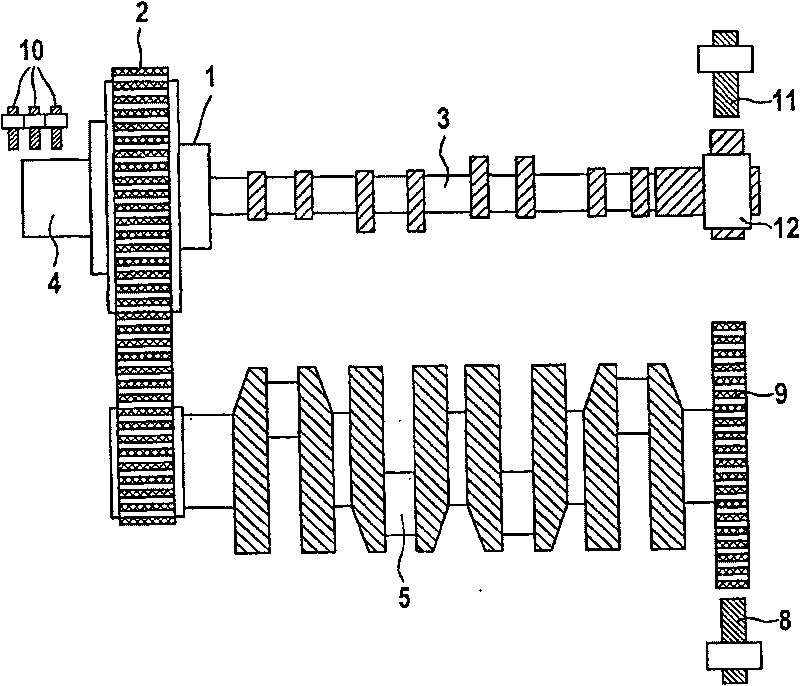

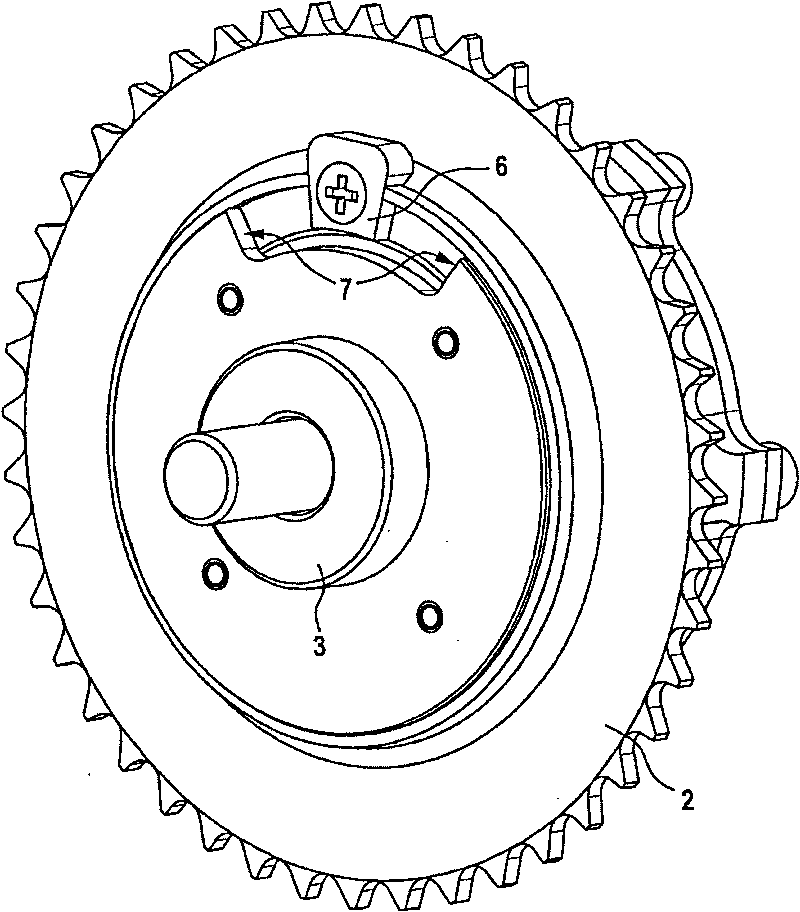

[0035] refer to figure 1 , the adjusting device of the piston internal combustion engine relative to the camshaft 3 of the crankshaft 5 includes a speed change transmission mechanism 1, which is constituted as a three-shaft transmission, has a transmission shaft fixed with the crankshaft, and a driven shaft fixed with the camshaft and an adjustment shaft. The variable gear can be a planetary gear, for example an epicyclic gear and / or a swash plate gear.

[0036] The transmission shaft is connected in a rotationally fixed manner to the camshaft gear 2 , which forms a drive connection in a known manner via a chain or toothed belt to a rotationally fixed crankshaft gear on the crankshaft 5 of the internal combustion engine. The driven shaft and the camshaft 3 are connected in a torque-proof manner. The rotor of the adjustment shaft and the motor 4 is connected in a torque-proof manner. The transmission 1 is integrated in the sleeve of the camshaft gear 2 .

[0037] In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com