Device for limiting current of the resistive type with a strip-shaped high TC superconductor

A current-limiting device and superconductor technology, applied in superconducting devices, devices and circuits that can be switched between superconducting and normal conducting states, can solve problems such as buffer layer breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

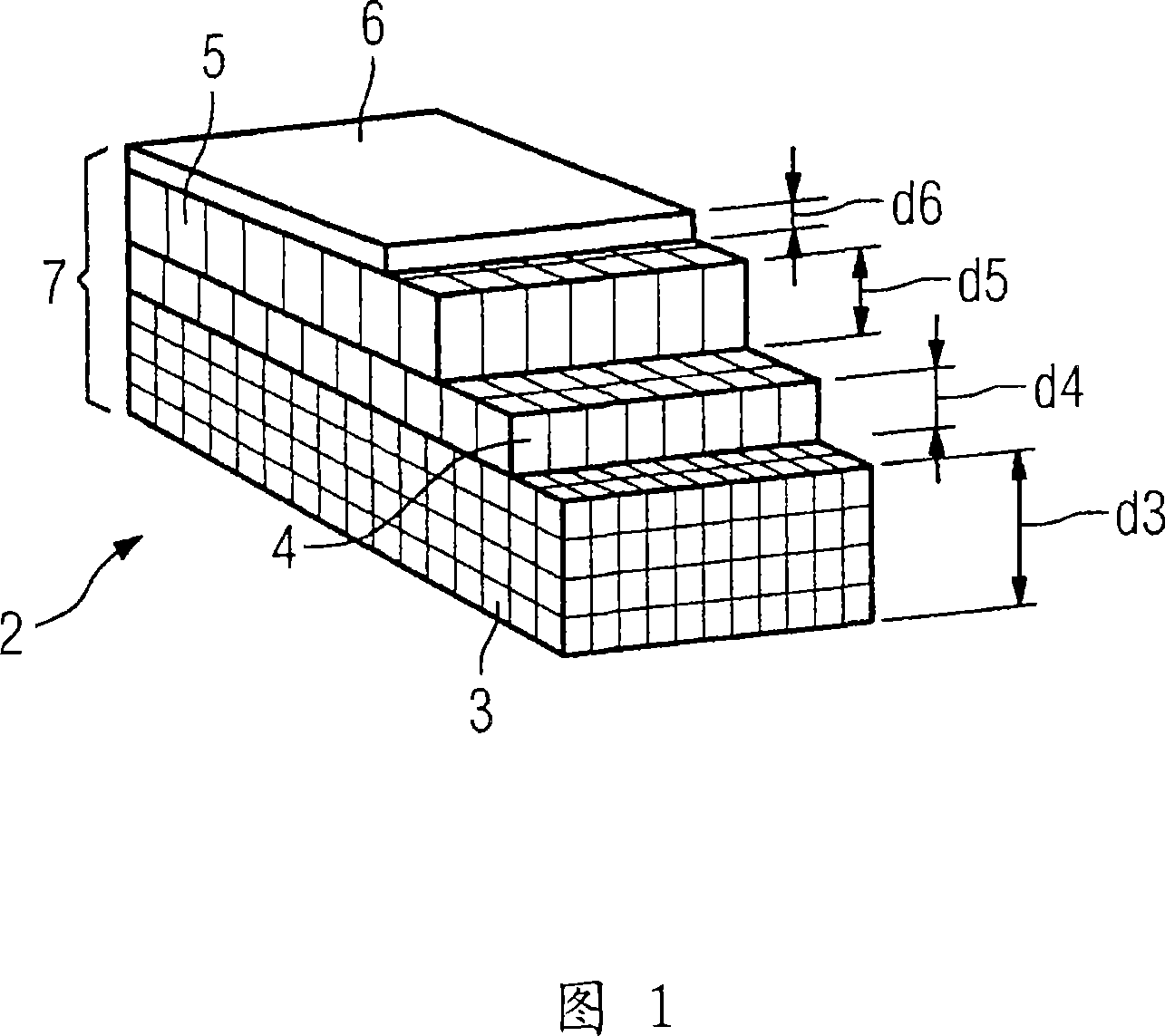

[0019] The strip conductors shown generally at 2 in FIG. 1 are based on the per se known embodiment of so-called YBCO strip conductors or “YBCO-coated conductors”. In this figure:

[0020] 3 denotes a substrate strip consisting of a normally conductive substrate metal of thickness d3,

[0021] 4 denotes at least one buffer layer of a special oxidized buffer material with a thickness d4 arranged on the substrate strip,

[0022] 5 represents the HTS layer composed of YBCO with a thickness of d5,

[0023] 6 denotes a protective layer consisting of a normally conductive protective layer metal of thickness d6, which serves as a protective or contact layer, and

[0024] 7 represents a conductor structure composed of the above four parts.

[0025] Here, the above parts can be built as follows:

[0026] - the metal substrate strip 3 is made of nickel, a nickel alloy or special steel, the thickness d3 of which is approximately 50 to 250 μm,

[0027] - at least one buffer layer or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com