Automatization device of high-precision copper strap horizontal casting machine assembly

An automatic device, a technology of horizontal continuous casting, applied in the program control and electrical program control of the sequence/logic controller, etc., can solve the problems of difficult maintenance of industrial computer software, easy wear and tear of the carbon brush of the DC servo motor, and reduce the The effect of field wiring and maintenance workload, high reliability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

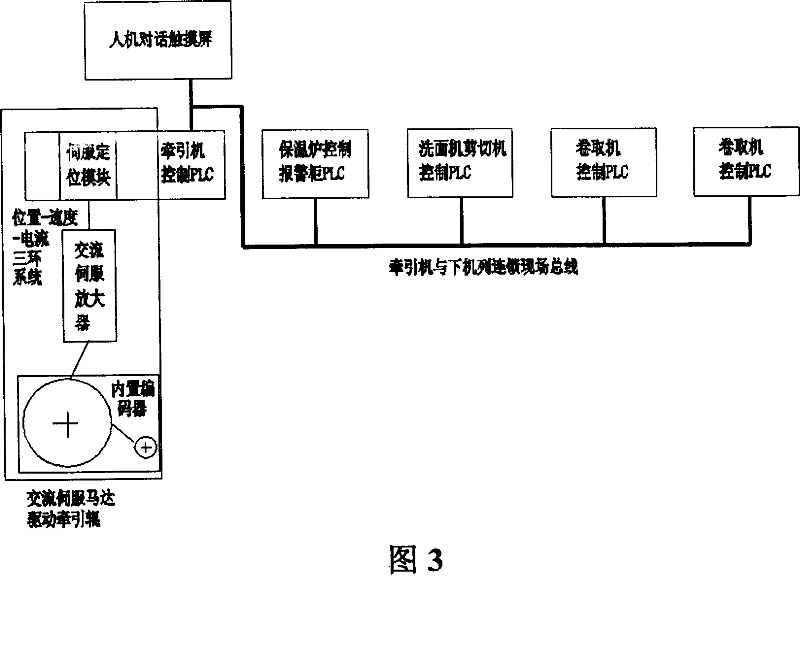

[0016] It can be seen from Fig. 3 that the device of the present invention includes: traction roller, face washing, shearing PLC, pre-rolling PLC, back-rolling PLC, traction PLC; also includes man-machine dialogue screen, AC servo amplifier, AC servo motor, holding furnace PLC; Described traction PLC links to each other with washing face, shearing PLC, front volume PLC, back volume PLC through field bus, and through the man-machine dialogue screen that links to each other with traction PLC, washes face, shears PLC, front volume PLC, back volume PLC The data is reflected on the man-machine dialogue screen; the traction PLC is also connected with the AC servo amplifier and the holding furnace PLC respectively, and the data of the AC servo amplifier and the holding furnace PLC are reflected on the man-machine through the man-machine dialogue screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com