Liquid-electricity welding method

A welding method and electro-hydraulic technology, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of large investment and unit cost, high cost, insufficient flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

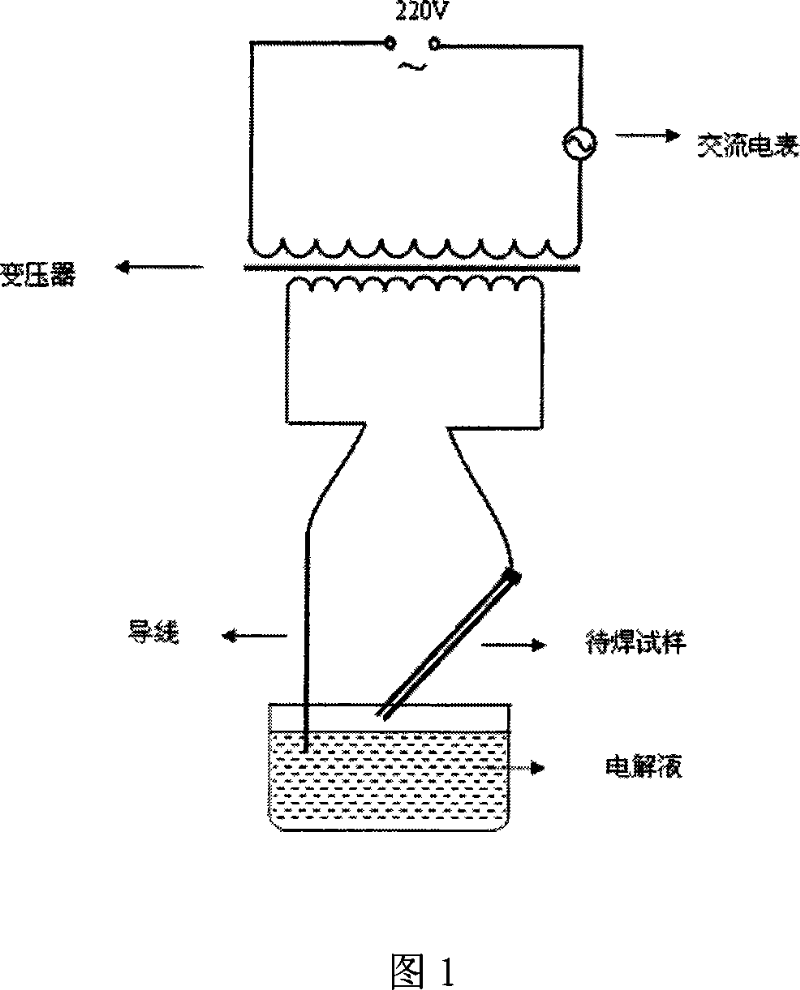

[0021] As shown in Figure 1, the entire welding system can be roughly regarded as composed of two parts according to its functions: (1) The power supply system including power supply, transformer, ammeter, etc. For the part of welding process parameters, according to the test, the required voltage for welding can be welded from 0V-380V; (2) The welding zone composed of the workpiece to be welded and the electrolyte is used by using a water-soluble salt solution , its components include water-soluble nitrates, nitrites, oxalates, carbonates, bicarbonates, phosphates, sulfates, sulfites and acetates, one or more of the above solution. If the content of each component is a single type of salt solution, the highest is the saturated solubility of the salt. For example, in a NaCl solution at 20°C, a maximum of 36 grams of NaCl can be dissolved in 100 grams of water; The percentage can be from 0% to 100%. A specific example: use NaCl saturated solution to form an electrolyte with g...

Embodiment 2

[0025] The setting of the welding circuit of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com