Typeset apparatus and porous printing apparatus

A technology for printing cylinders and plates, applied in stencil printing equipment, printing, printing presses, etc., can solve the problems of unstable movement, winding, and it is difficult to completely eliminate winding, and achieve the effect of simple structure and cheap structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

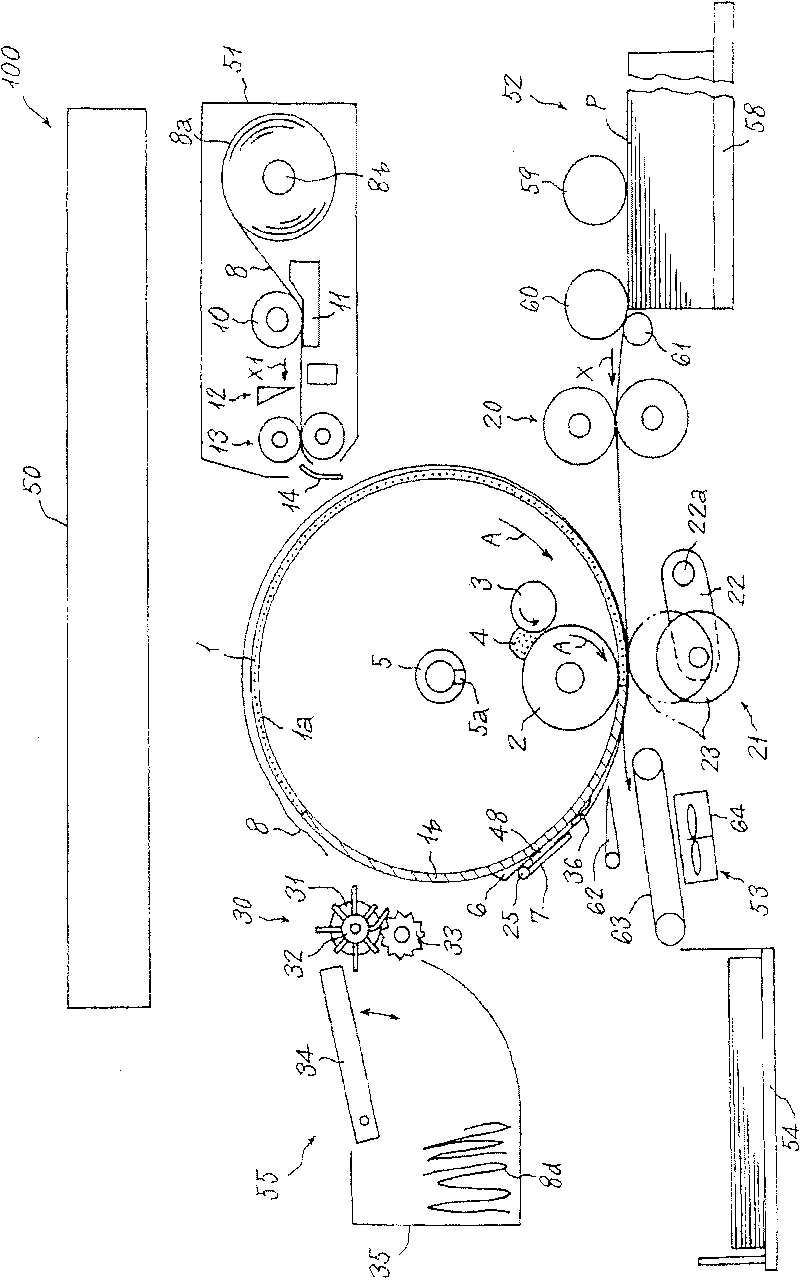

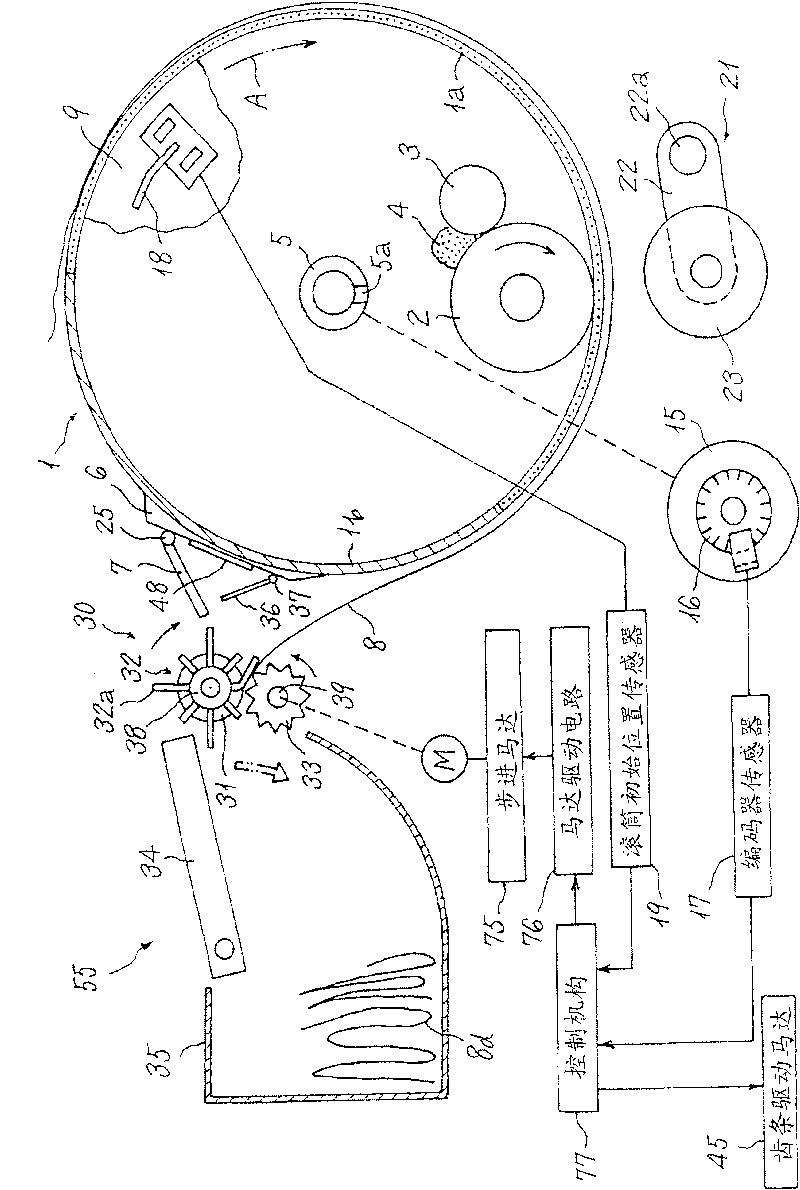

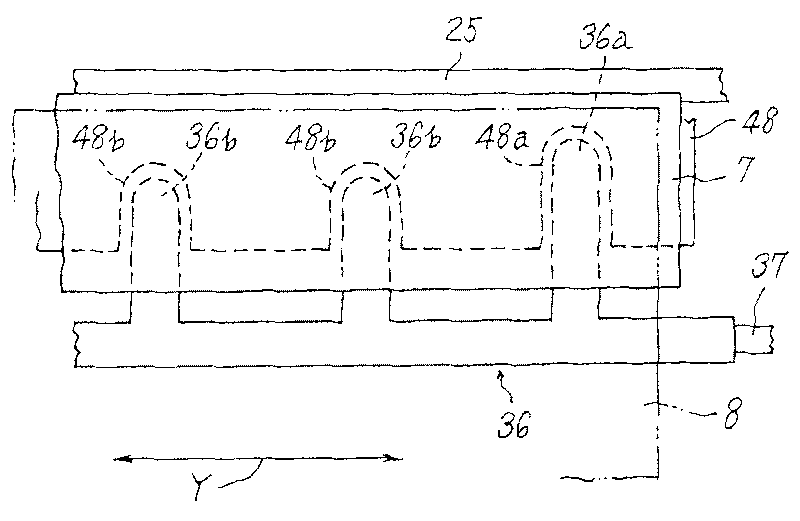

[0053] refer to Figure 1 to Figure 11 The first embodiment of the present invention will be described.

[0054] First, refer to figure 1 The configuration of the stencil printing apparatus 100 of this embodiment will be briefly described. The stencil printing device 100 includes an image reading device (scanning device) 50, a plate making device 51, a paper feeding device 52, a printing cylinder 1, a paper discharge transport device 53, a paper discharge tray 54 as a paper discharge table, a typesetting device 55, and the like. The image reading device (scanning device) 50 reads an image of an unillustrated document, and has a known configuration. The plate making device 51 makes a plate 8 and supplies plates based on image information read by the image reading device 50 or image information input from an externally connected device such as a personal computer (not shown). The paper feeding device 52 supplies printing paper P (hereinafter referred to as “paper P”) on a pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com