Combustible treating device

A processing device and mechanical sealing device technology, applied in the field of combustibles processing devices, can solve the problems of large power, high maintenance and management costs, and a large amount of regular maintenance and replacement of crushing tools, and achieve the effect of reducing maintenance and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

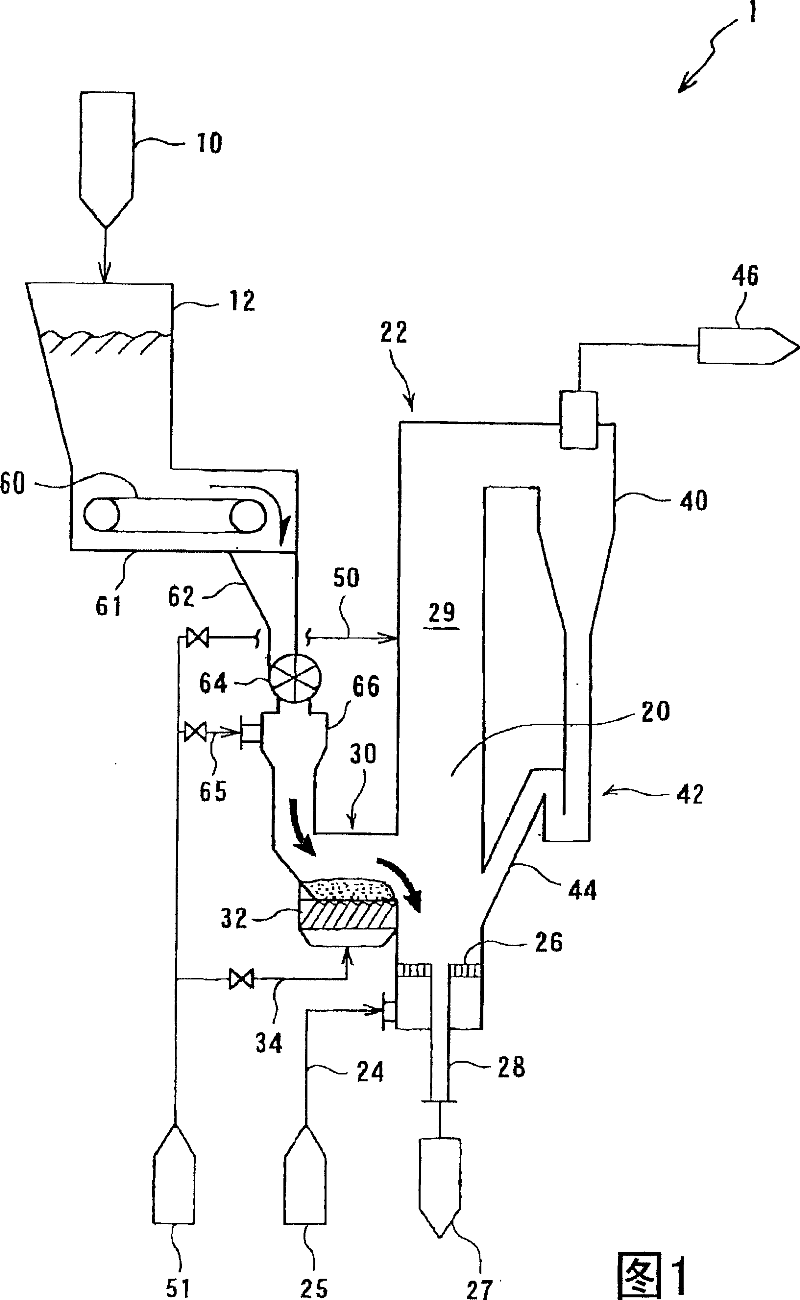

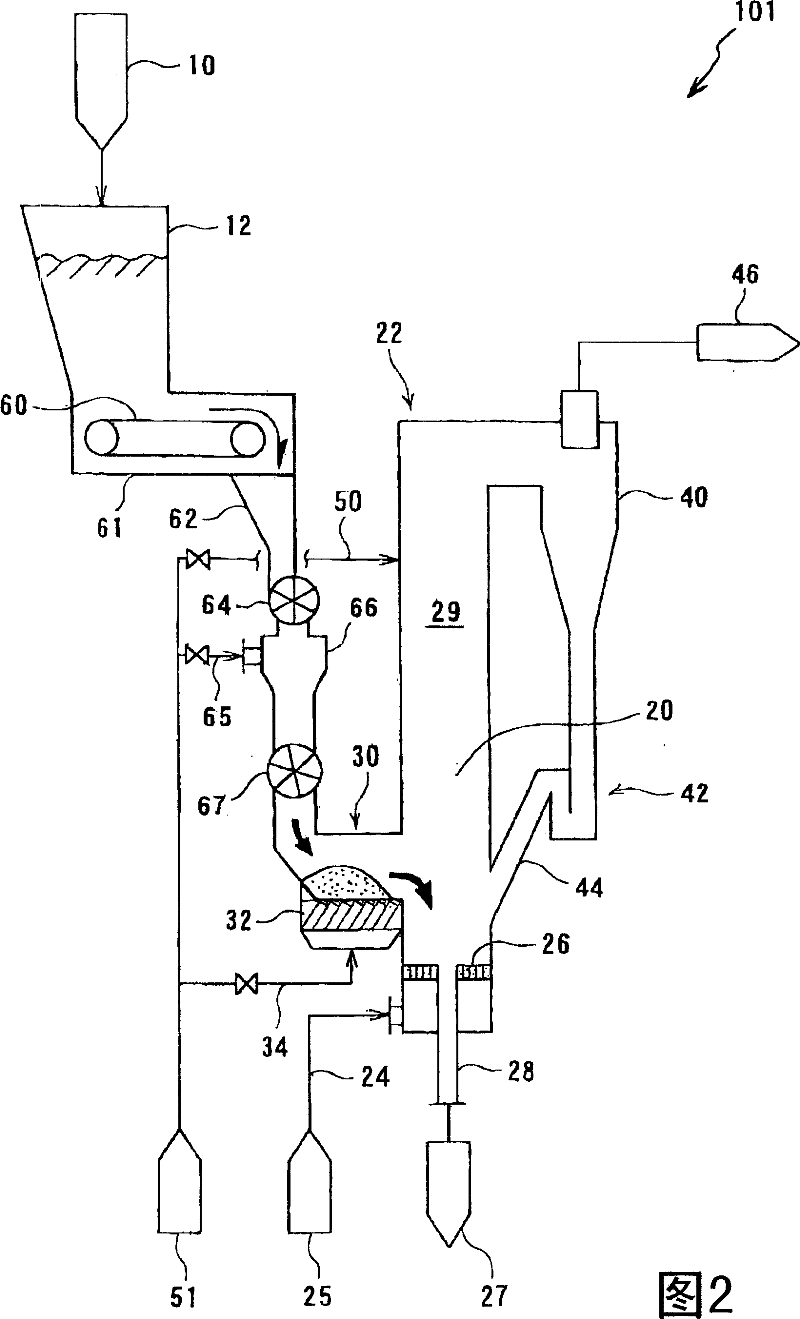

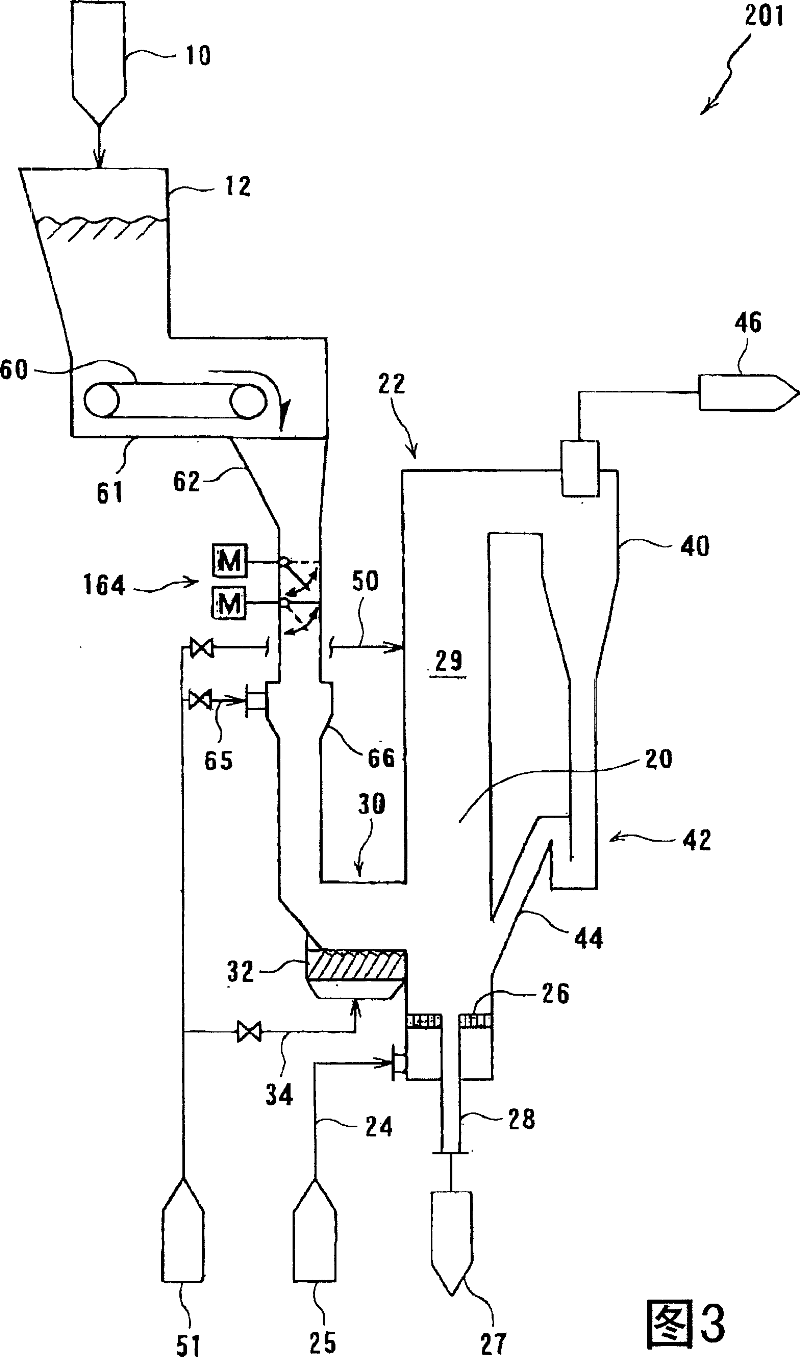

[0016] The implementation of the combustibles processing device of the present invention will be described in detail below with reference to FIGS. 1 to 5 . In addition, in FIGS. 1 to 5 , the same or corresponding components are given the same reference numerals to omit overlapping descriptions.

[0017] FIG. 1 shows a schematic view of a combustibles processing apparatus 1 constituting a first embodiment of the present invention. As shown in Figure 1, the combustible treatment device 1 has: a hopper 12 for dropping combustibles 10; a circulating fluidized bed boiler 22 with a combustion chamber 20 for burning combustibles; a thermal decomposition chamber 30 connected with the circulating fluidized bed boiler 22 ; The cyclone separator 40 that separates solids such as combustion ash or flow medium from the combustion gas generated in the combustion chamber 20 .

[0018] The hearth portion of the combustion chamber 20 is provided with a distribution plate 26, which is used to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com