Automatic analyzer

An automatic analysis device and colorimetric analysis technology, applied in the direction of analyzing materials, analyzing materials by chemical reaction, and analyzing materials by observing the influence on chemical indicators, which can solve the problem of increased reagent costs and colorimetric analysis. Reduce processing capacity and other issues to achieve the effect of improving processing capacity and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, embodiments of the present invention will be described using the drawings.

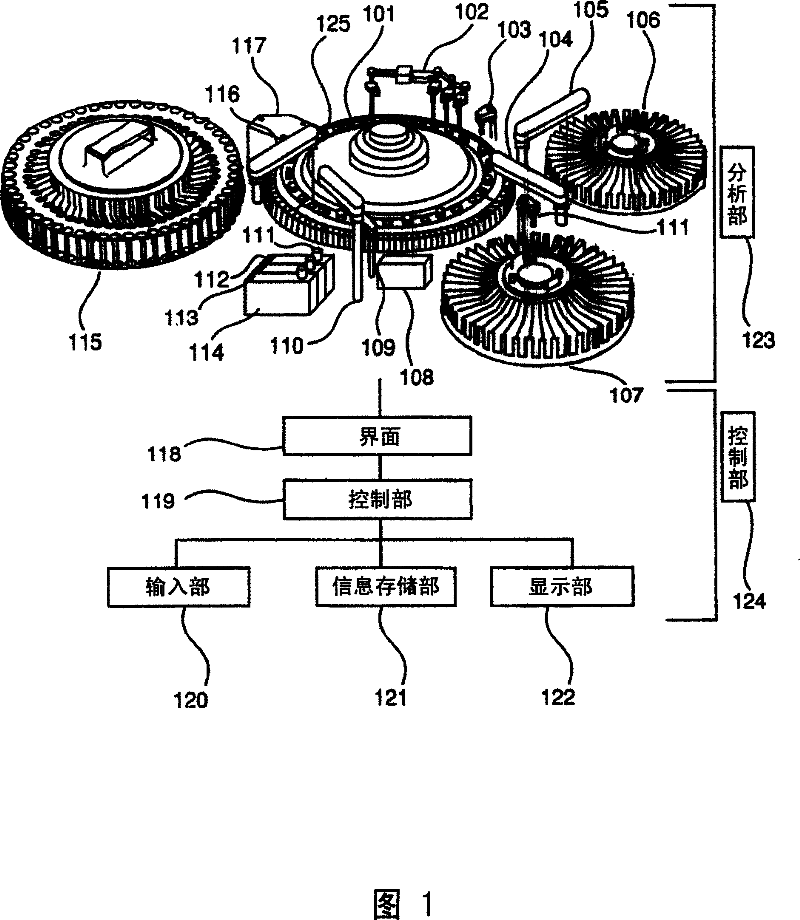

[0014] Fig. 1 shows an example of an automatic analyzer to which the present invention is applied. First, the entire automatic analysis device is composed of the analysis unit 123 and the control unit 124 . The colorimetric analysis unit is equipped with the following components: a sample disk 115 as a sample moving device that holds a plurality of sample containers and moves each sample container to a position where the sample is sucked; Reagent disks 106, 107 of a reagent moving device that move each reagent container to a position where the reagent is sucked; a reaction container 101 for reacting a sample and a reagent; a plurality of reaction containers 101 are arranged in Ring-shaped, reaction disk 125 functioning as a reaction line; a sample pipetting mechanism 116 for dispensing a sample into the reaction vessel 101; a reagent pipetting mechanism for dispensing a reagent in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com