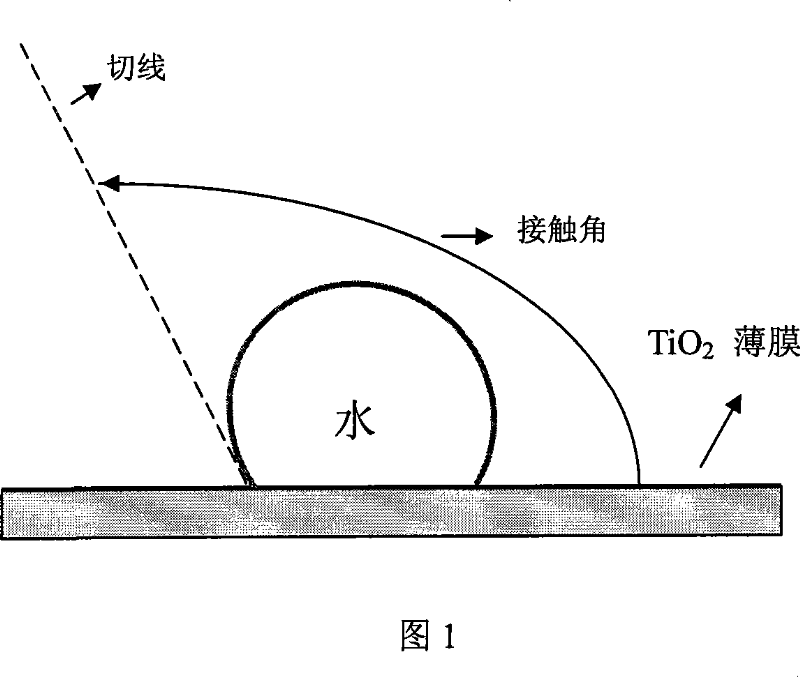

Self-cleaning oxidate film and preparation method and usage thereof

An oxide film, self-cleaning technology, applied in chemical instruments and methods, liquid chemical plating, other chemical processes, etc., can solve problems such as hindering the invention of self-cleaning oxide films, low conductivity, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

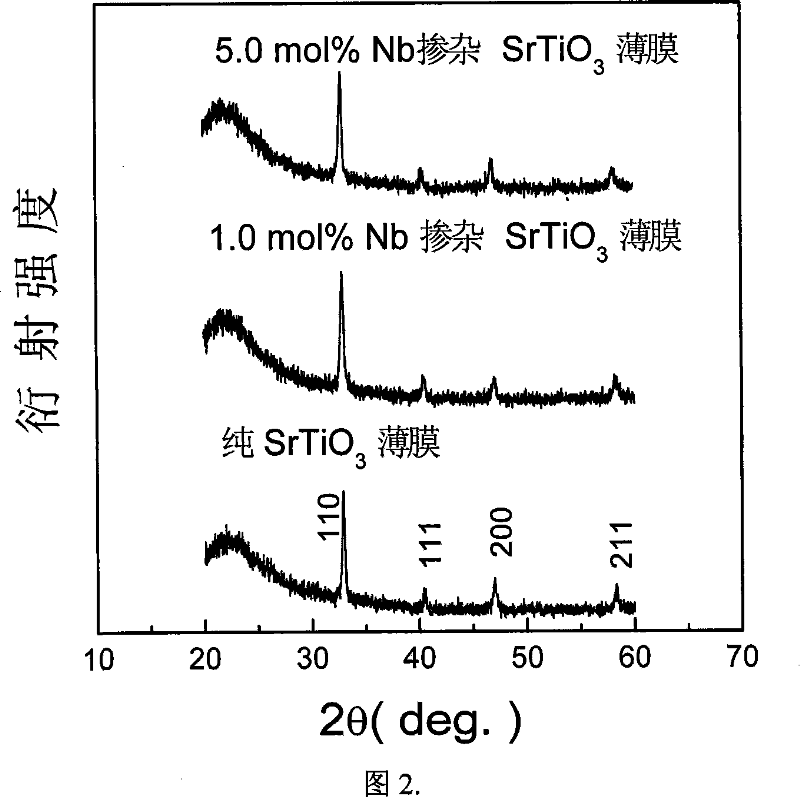

[0046] Embodiment 1. A kind of self-cleaning oxide thin film is characterized in that this thin film is made of metal ion Nb 5+ Doped SrTiO 3 , with the formula Nb:SrTiO 3 Said that its doping concentration is 1.0mol%; the thickness of the oxide film is 0.4 microns.

Embodiment 2

[0047] Embodiment 2. a kind of self-cleaning oxide film is characterized in that this film is made of metal ion Al 3+ Doped SrTiO 3 , with the formula Al:SrTiO 3 Said that its doping concentration is 1.0%; the thickness of the oxide film is 0.5 microns.

Embodiment 3

[0048] Embodiment 3. a kind of self-cleaning oxide film is characterized in that this film is made of metal ion Zn 2+ Doped SrTiO 3 , with the formula Zn:SrTiO 3 Said that its doping concentration is 1.0%; the thickness of the oxide film is 0.6 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com