Full-automatic washing machine and laundry drier

A fully automatic washing machine, washing and drying machine technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems that clothes cannot fall naturally, have no drying function, lose design requirements, etc., and achieve low wear rate of clothes , Decontamination is clean and thorough, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

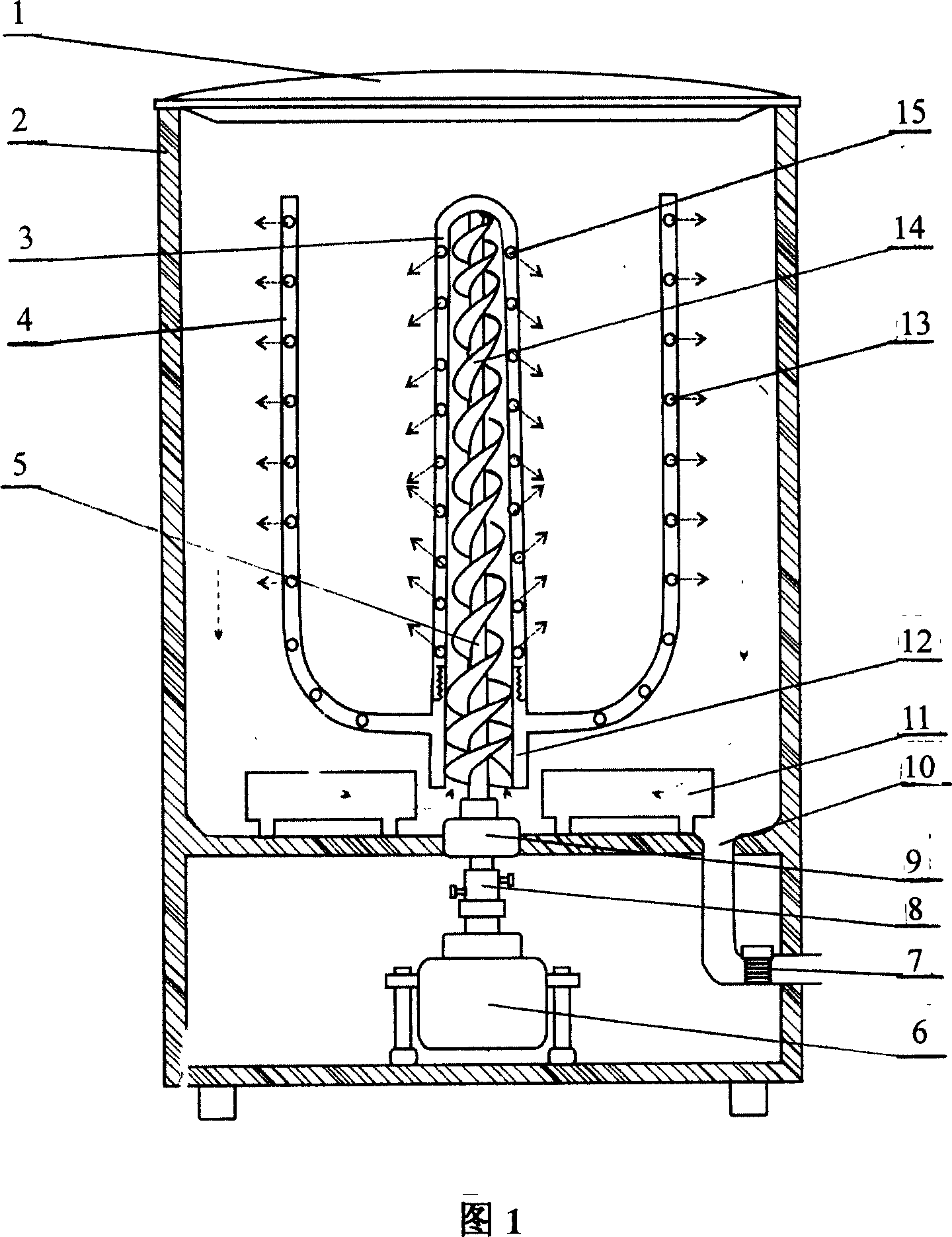

[0025] In the fully automatic washing machine of Fig. 1, the centrifugal barrel 4, the spray pipe 3, the spiral blade 14, the water seal 9, the connector 8 and the motor 6 in the casing 2 are all connected with the transmission shaft 5 as the center; Many spray holes 15 are arranged on the pipe wall of the spray pipe, the center line of the spray hole of the upper half of the spray pipe is obliquely downward, the center line of the spray hole of the lower half is obliquely upward, and the bottom of the spray pipe is the one without through holes in the pipe wall. Suction pipe 12; Many dehydration holes 13 are arranged on the centrifuge barrel barrel wall. A group of evenly distributed vortex-blocking sheet groups 11, drain pipes 10, and drain valves 7 are arranged below the centrifuge bucket;

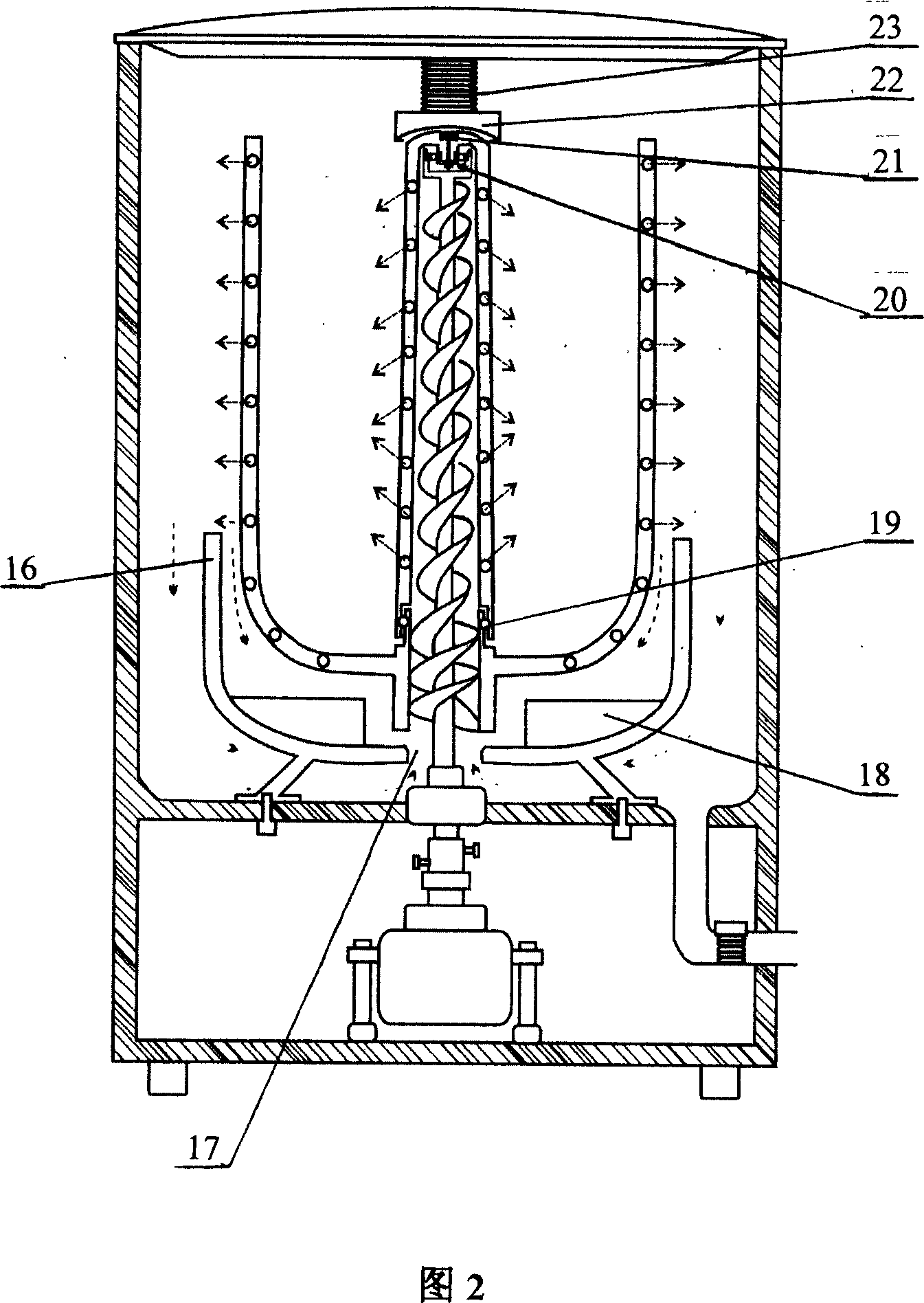

[0026] In the fully automatic washing machine shown in Fig. 2, the upper end of the spray pipe is connected to the transmission shaft with a ball bearing 20, and the water suction pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com