Crosscutting shear collecting and sampling knife changing combined unit

A combined device and cross-cutting shear technology, applied in the field of cross-cutting shears, can solve the problems of difficulty in realizing mechanized sampling operations, many auxiliary equipment of cross-cutting shearing units, and high labor intensity of manual work, so as to realize automatic standardized operations and improve The degree of mechanization and convenience, the effect of labor-saving, fast and safe sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

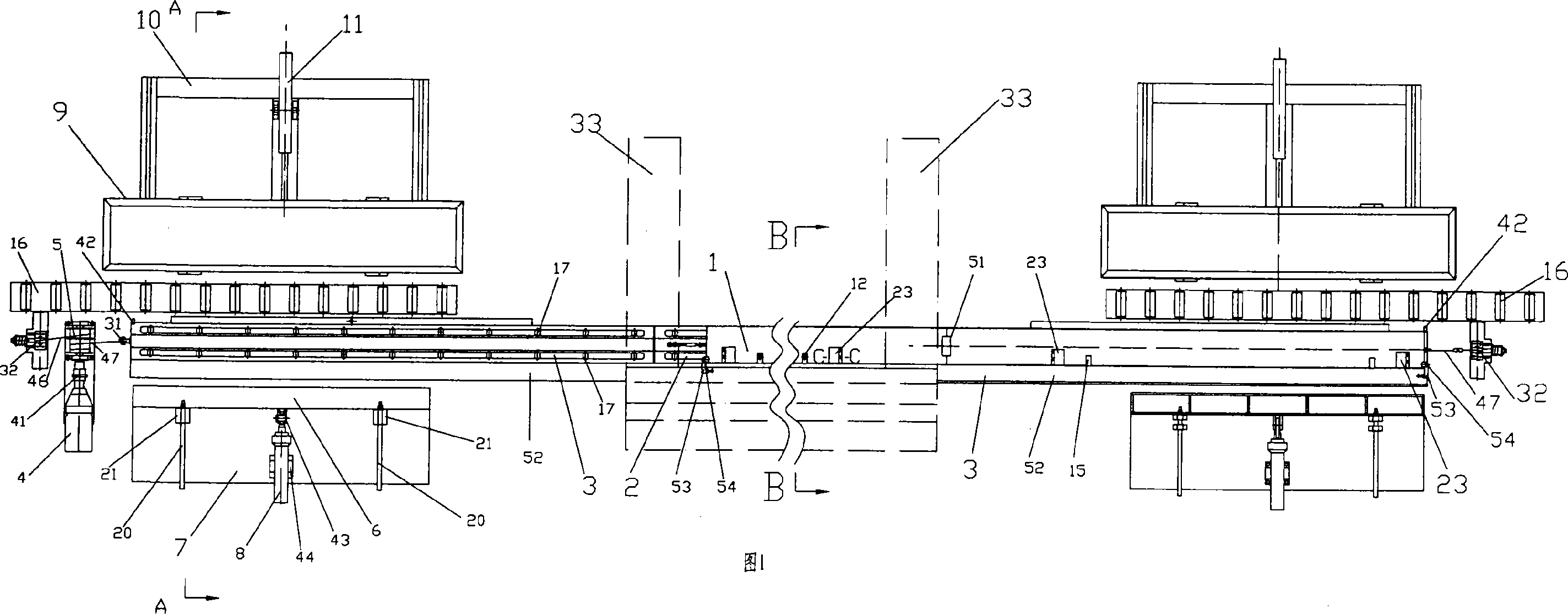

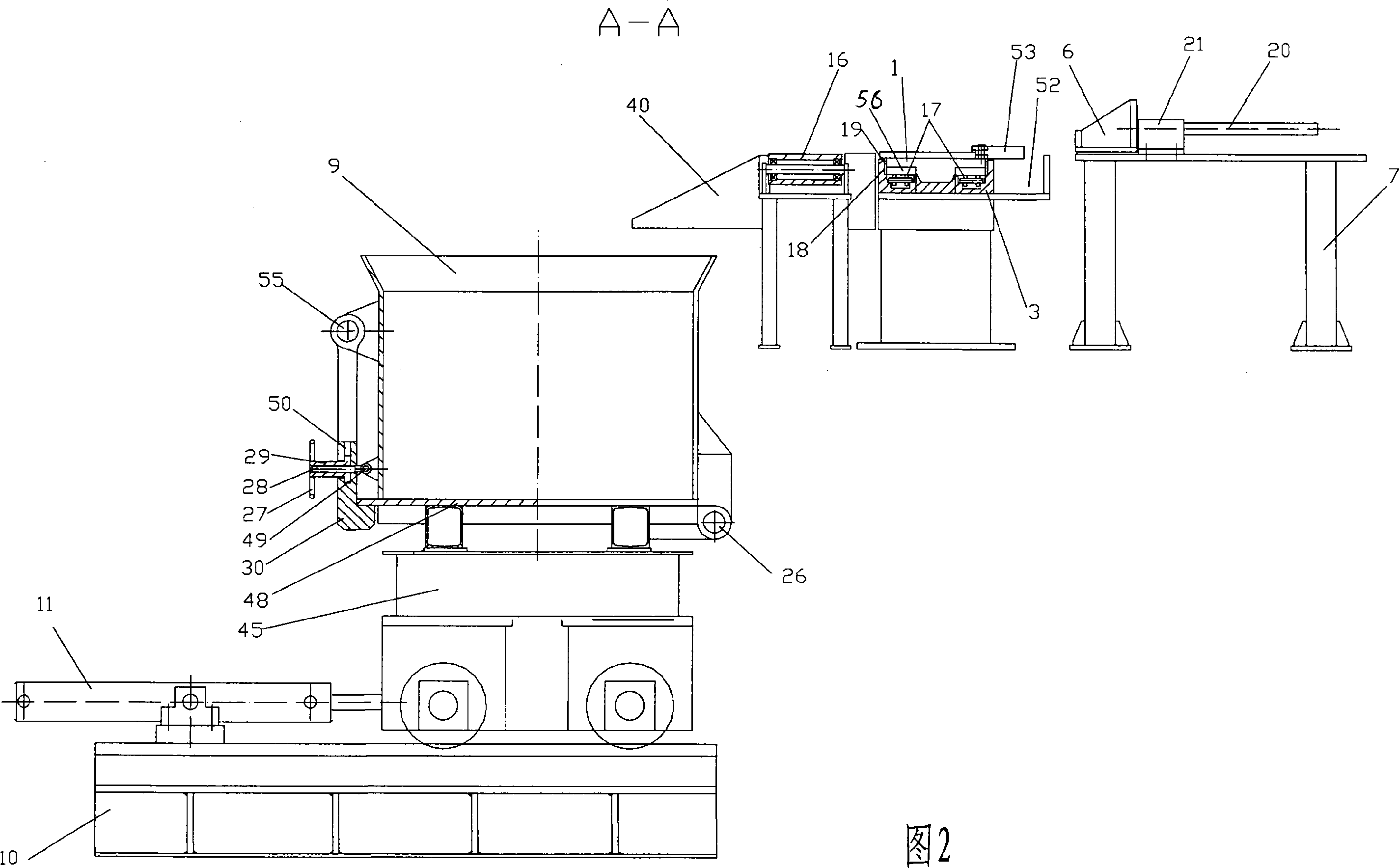

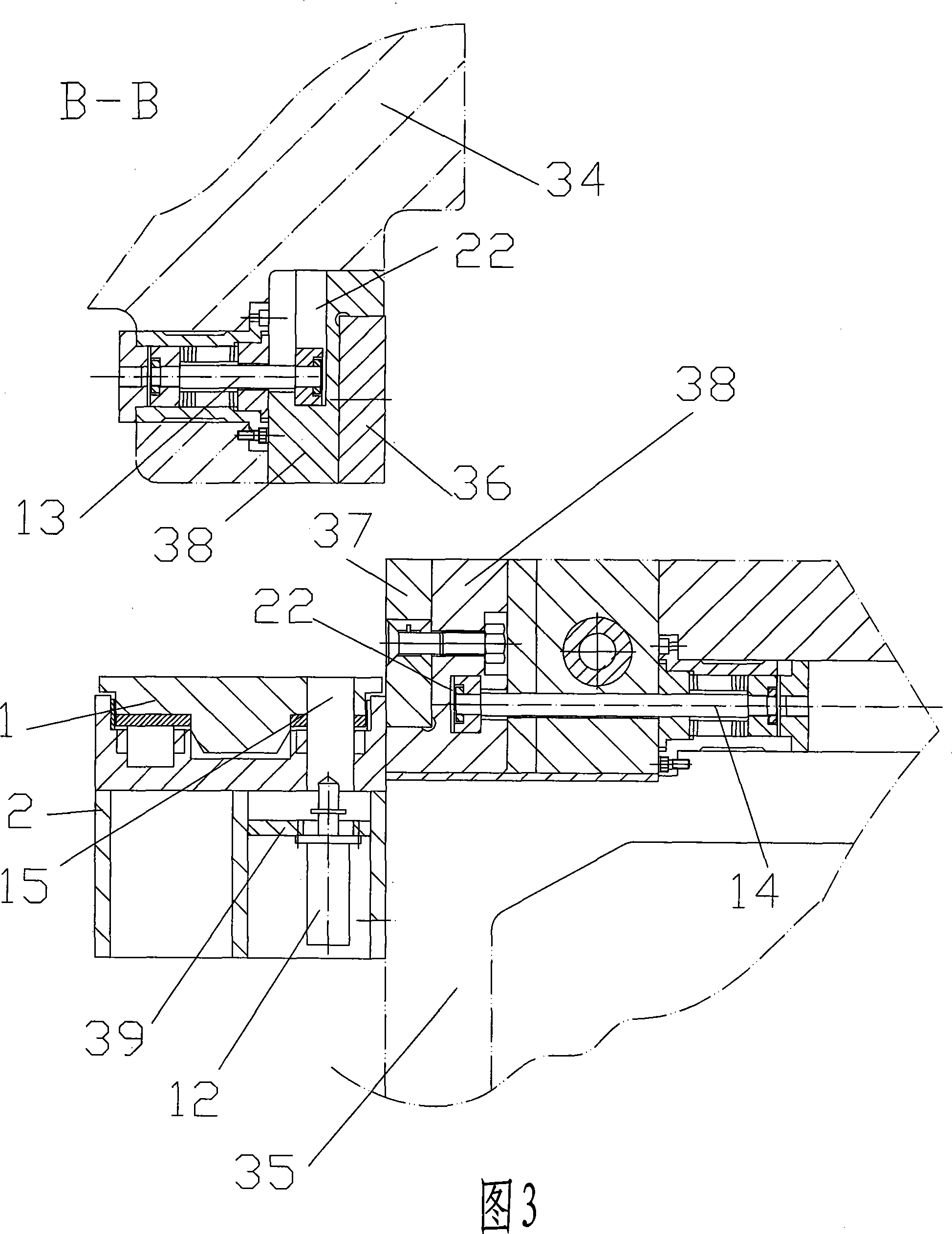

[0033] Refer to Figure 1. The inner pedestal 2 in the walking platform part is installed between the left and right frames 33 of the cross-cutting shears, and the two outer pedestals 3 are fixed on the foundations at both ends of the inner pedestal 2 and are butted with the inner pedestal 2 in the middle to form an integral pedestal. When the motor 4 drives the drum 5 to rotate forward and backward, the walking platform 1 slides to the left and right along the track on the integral platform under the traction of the wire rope. The walking table 1 is close to the lower knife rest 35 in the cross-cutting shears, and the table surface corresponds to the upper scissors 36.

[0034] Still refer to Figures 1 and 2. The pusher seat 7 and the basket car seat 10 in the sampling part are symmetrically fixed on both sides of the left or right outer seat 3. The pusher 6 is a rectangular frame plate, the top surface is an inclined surface, and the moving surface faces the overall seat, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com