Dynamic piezoelectric or electrostrictive ceramic drive power supply

A stretchable and piezoelectric technology, applied in the field of drive power circuits, can solve the problems of insufficient peak power of the drive, low frequency response of the drive, and high power dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

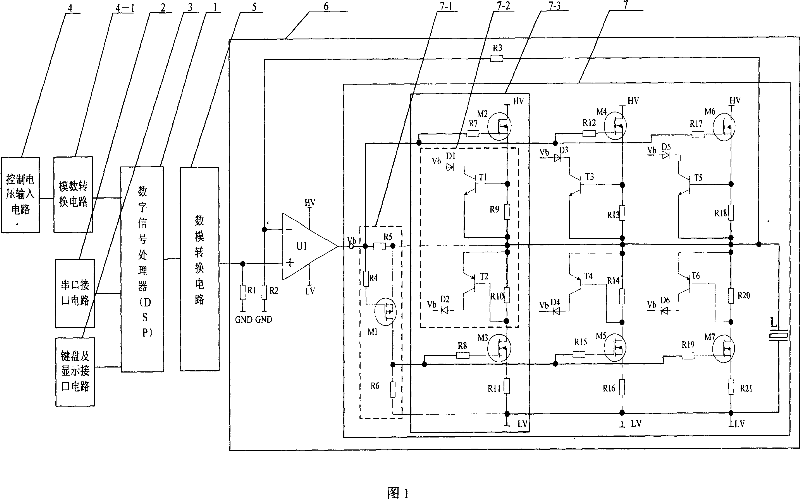

[0012] Embodiment 1: As shown in Figure 1: the piezoelectric ceramic driving power supply circuit includes a digital signal processor 1, an RS232 interface circuit 2, a keyboard and a display interface circuit 3, a control voltage input circuit 4, an analog-to-digital conversion circuit 4-1, a digital Analog conversion circuit 5, high voltage amplifying circuit 6. The specific connection method is as follows: the output terminal of computer and RS232 interface circuit 2 is connected to the input terminal of digital signal processor 1, the output terminal of keyboard and display interface circuit 3 is connected to the input terminal of digital signal processor 1, and the output of external analog input signal 4 is connected The terminal is connected to the input terminal of the analog-to-digital conversion circuit 4-1, the output terminal of the digital-to-analog conversion circuit 4-1 is connected to the input terminal of the digital signal processor 1, and the output terminal ...

Embodiment 2

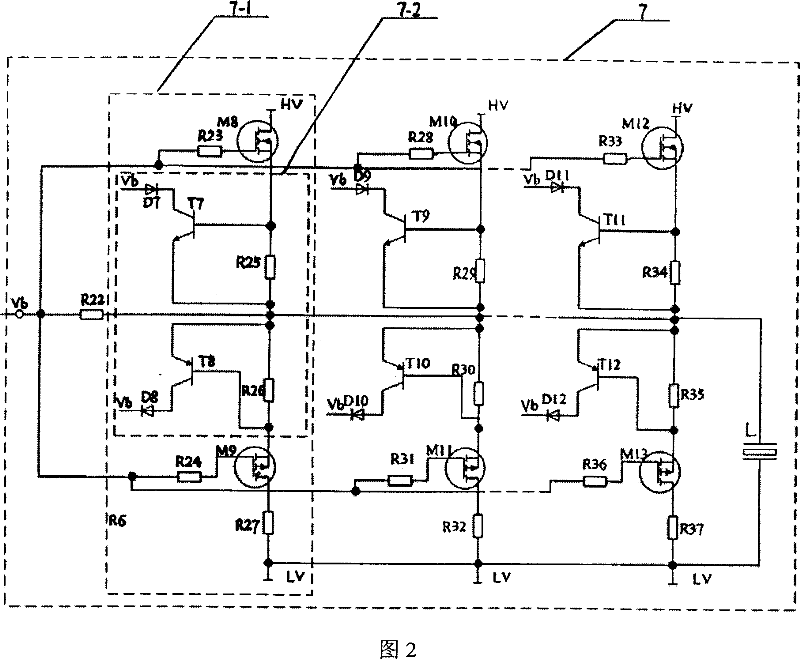

[0018] Embodiment 2: The difference between Example 2 and Example 1 is that the driving circuit is different. The driving circuit of Embodiment 2 is shown in FIG. , M9, R23, R25, R26, R27, R24, the specific connection relationship is that the gate of M8 is connected to one end of R23, the other end of R23 is connected to the output end of the high-voltage operational amplifier U1, the drain of M8 is connected to the high-voltage terminal HV, and M8 The source of R25 is connected to the common point of one end of resistor R25 and the base of T7, the other end of R25 is connected to one end of R26, and one end of R22 is connected at the same time, the other end of R26 is connected to the source of M9, and the gate of M9 is connected to one end of R24. The other end of R24 is connected to the output end of the high voltage operational amplifier U1, the drain of M3 is connected to one end of the resistor R27, and the other end of R27 is connected to the low voltage end LV. The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com