Anti-wedging type high speed mixer drum

A technology of high-speed mixing and stirring shafts, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as lowering product quality, improper crushing of stones, and harsh working conditions, so as to reduce power consumption and shorten Stirring time, the effect of avoiding wedge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

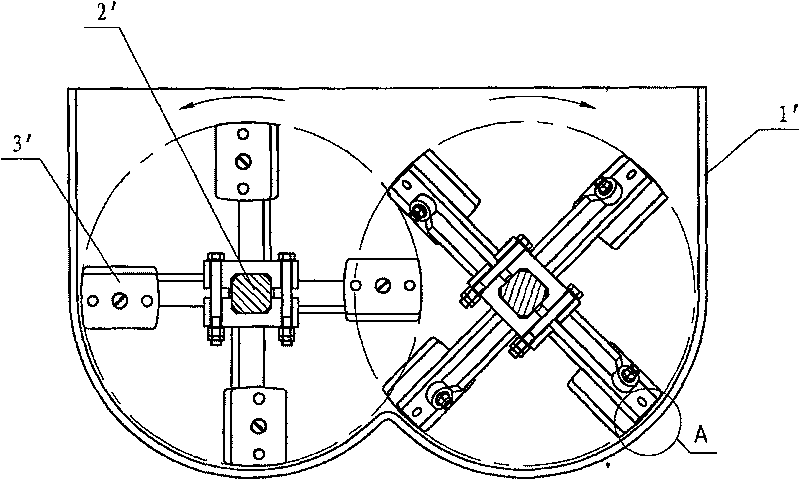

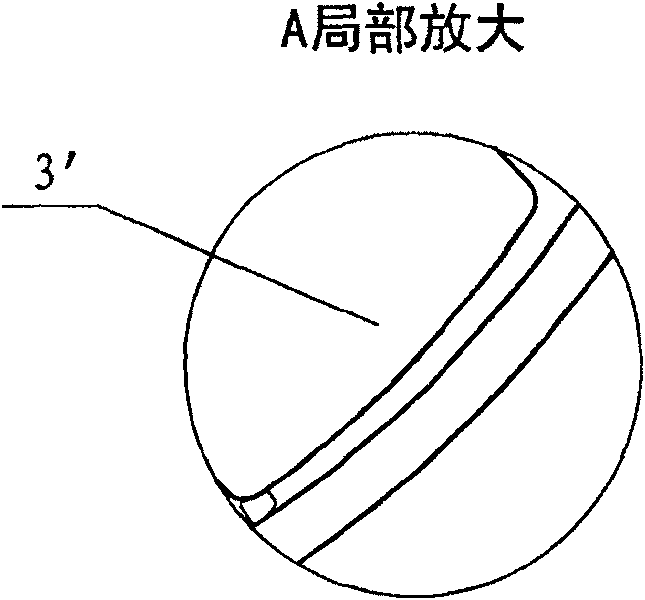

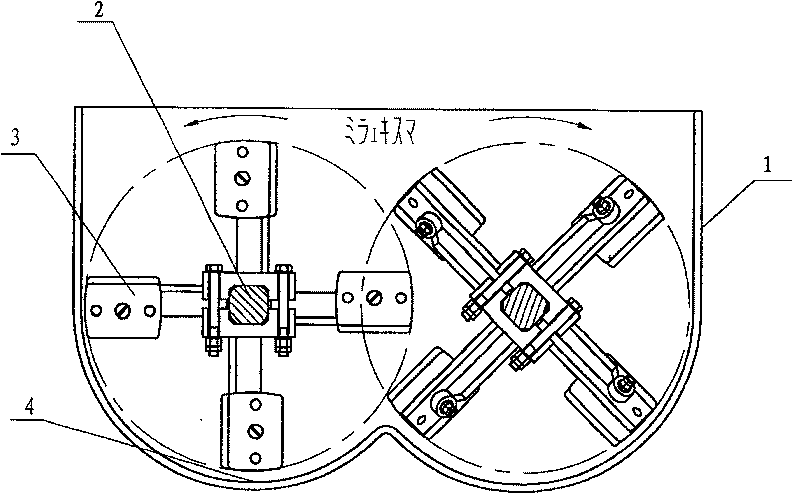

[0011] Such as image 3 , Figure 4 As shown, a stirring shaft 2 is installed in the cylinder body 1 of the anti-wedge extrusion high-speed mixing cylinder, and a paddle 3 is installed on the stirring shaft. Wear-resistant liners are distributed on the arc-shaped bottom surface 4 of the cylinder body, and the stirring shaft and the paddle There is an eccentric distance between the center of rotation of the blade and the center of the arc on the bottom surface of the cylinder, so that the distance between the running track of the end of the blade and the wear-resistant liner increases gradually in the direction of the blade. Such as Figure 4 As shown, the eccentric distance may include a lateral eccentricity x and a vertical eccentricity y.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com