Treating device for sludge self-return aerobic bios

A technology of aerobic biology and treatment equipment, which is applied in the direction of aerobic process treatment, sustainable biological treatment, biological water/sewage treatment, etc., and can solve the problems of sludge not returning in time, sludge floating phenomenon, sludge accumulation, etc. Achieve the effect of saving sludge return equipment and power costs, preventing sludge swelling, and reducing sludge flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

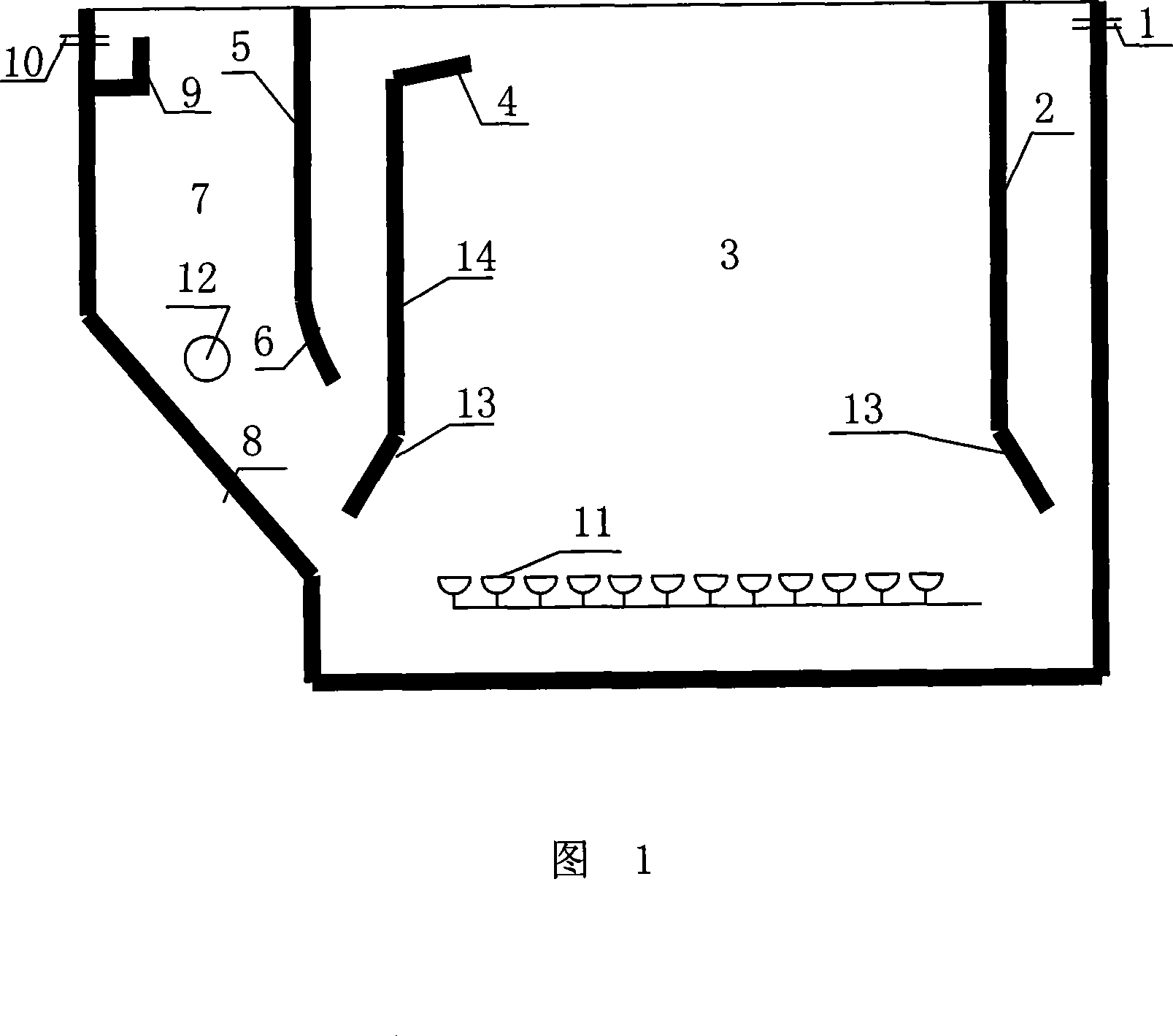

[0016] As shown in Figure 1, a sludge self-reflux aerobic biological treatment device includes a tank body 14, the two ends of the tank body 14 are respectively provided with a water inlet 1 and a water outlet 10, and the tank body 14 is provided with a The diversion area 15, the aeration area 3 and the sludge sedimentation area 7 are separated by the plate 2 and the partition 14 but communicated at the bottom. The diversion swash plate 13 with an angle of 135 degrees, the ratio of the length of the sludge diversion buffer slant plate 4 to the width of the diversion area 15 is 1:0.8-1.2, which forms an angle of 15-30 degrees with the horizontal plane.

[0017] The lower end of the water inlet deflector 2 is provided with a deflector inclined plate 13 that forms an angle of 45-60 degrees with the horizontal plane.

[0018] An aeration device 11 is provided at the bottom of the aeration zone 3 .

[0019] The bottom of the sludge settling area 7 is provided with an inwardly incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com