Highpass digital filtering method of nutation frequency automatic tracking

A technology of nutation frequency and automatic tracking, applied in the direction of digital technology network, impedance network, electrical components, etc., can solve the problems of magnetic suspension bearing system impact, magnetic rotor nutation instability, cumbersome debugging process, etc., to achieve good filtering performance, The effect of simple debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

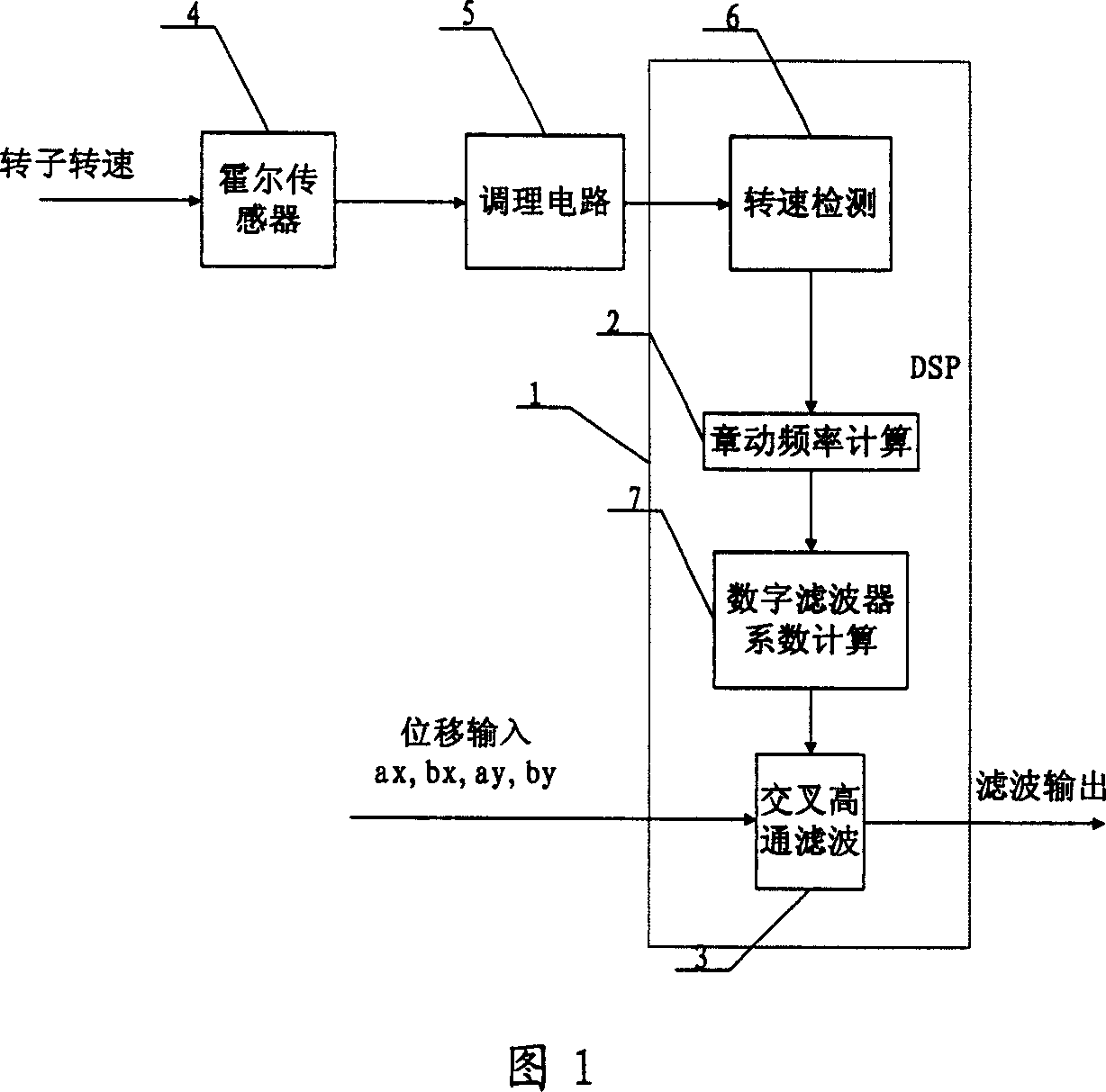

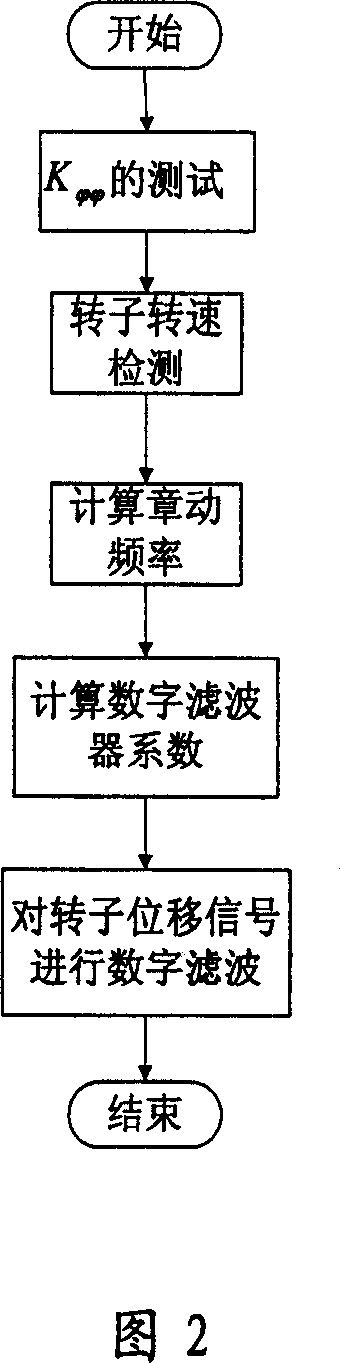

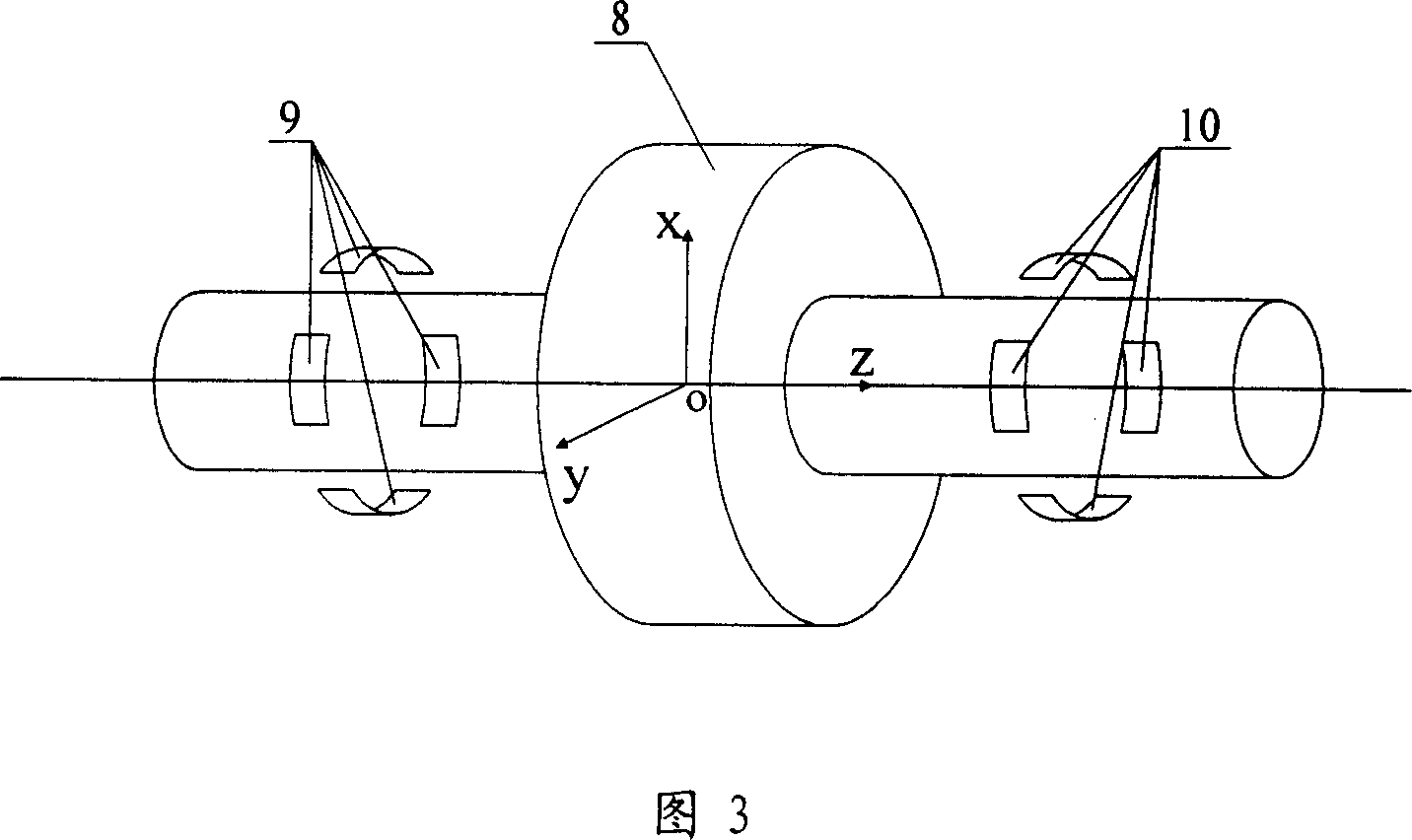

[0021] The present invention mainly comprises five steps: rotor speed detection, K Test, nutation frequency calculation, digital filter coefficient calculation, digital filtering. As shown in Figure 1, the hardware mainly includes three parts: Hall sensor 4, conditioning circuit 5, and DSP1. Rotational speed detection 6, nutation frequency calculation 2, digital filter coefficient calculation 7, and cross high-pass filter 3 are the internal parts of DSP1. algorithm. The rotational speed of the rotor is detected by the Hall sensor 4, and then sent to DSP1 after conditioning by the conditioning circuit 5, and the rotational speed Ω of the rotor is calculated by DSP1; the measured rotational speed Ω is substituted into the nutation frequency calculation formula (1) Online calculation of the nutation frequency f n , to realize automatic tracking of nutation frequency; with f n The coefficients of the digital filter are calculated for the cutoff frequency, and finally the onli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com