Microwave drying and screening integrated machine

A microwave drying and all-in-one machine technology, which is applied in the direction of drying solid materials, progressive dryers, heating to dry solid materials, etc., can solve the problems of easy plugging of wet materials, low product quality, low screening efficiency, etc., to achieve durability Good abrasiveness, uniform heating, good microwave attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

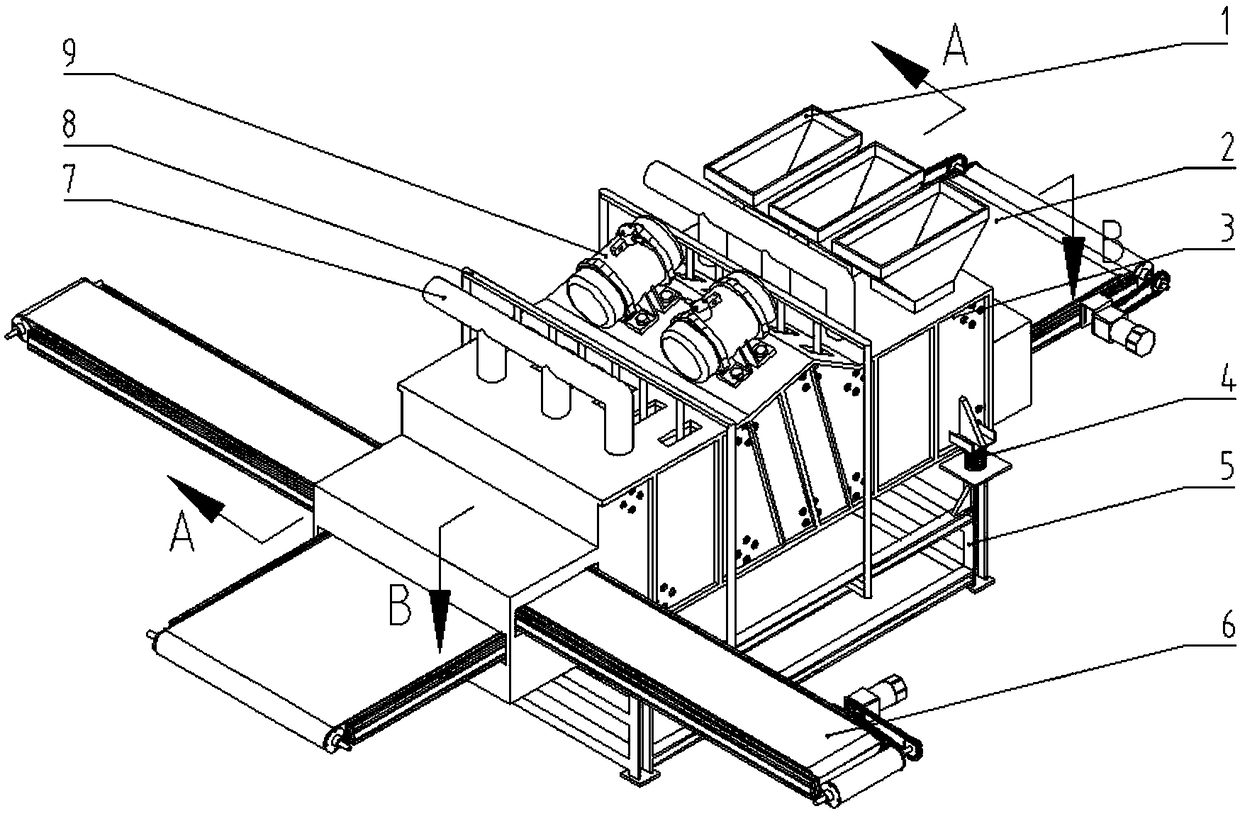

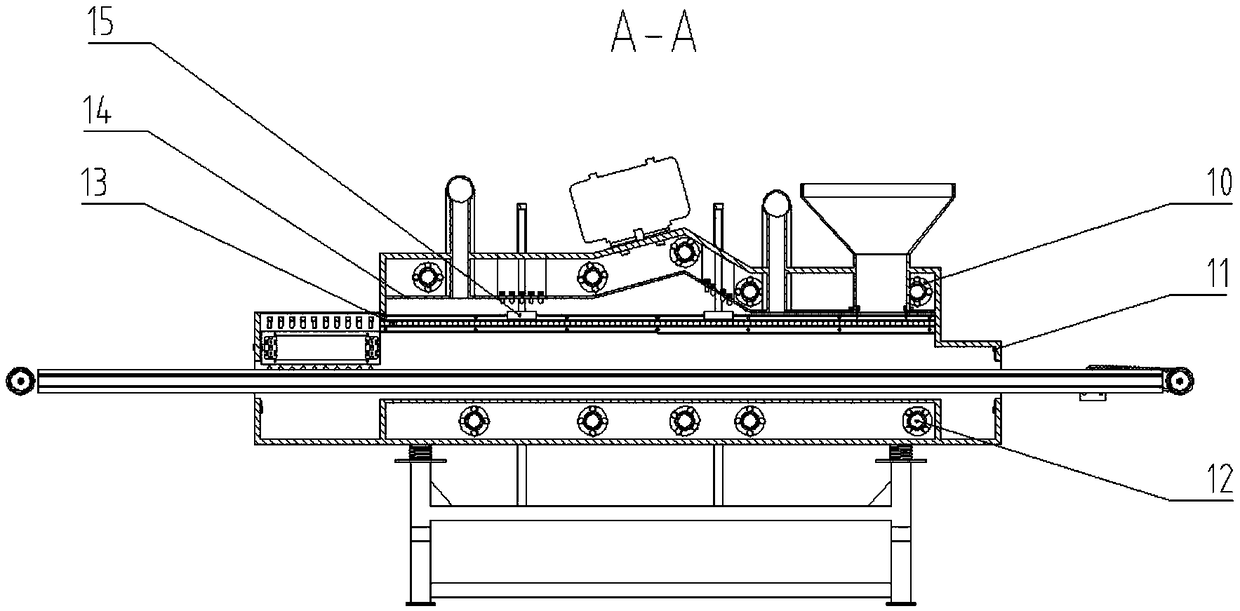

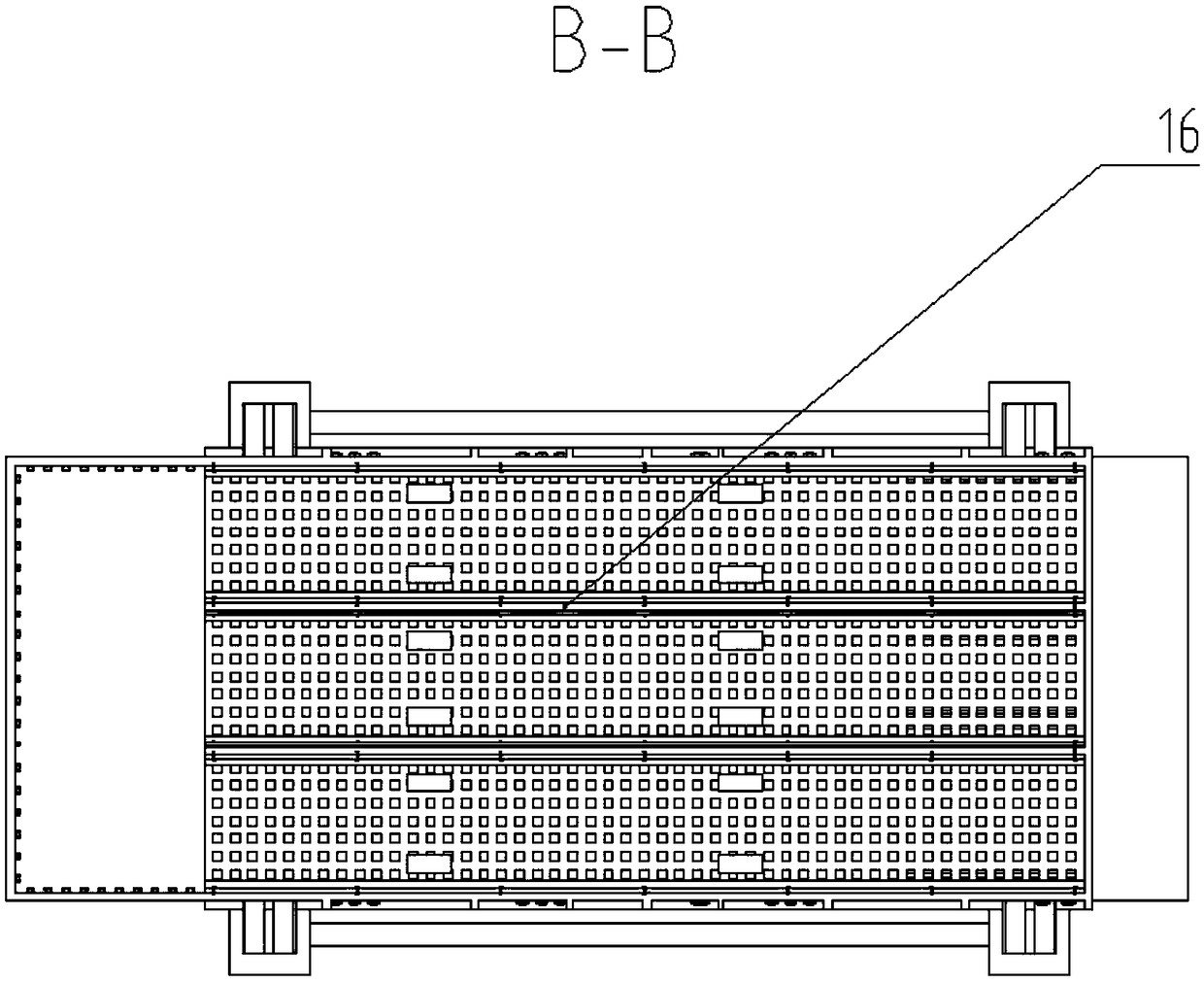

[0022] Such as Figure 1-3 As shown, the integrated microwave drying and screening machine of the present invention includes a sieve box 3, a base 5, an undersize conveyor belt 2, an oversize conveyor belt 6, a microwave radiator support rod 8, a vibration motor 9, a fixing flange 10, Microwave suppressor 11, beam 12, sieve plate 13, microwave radiator 15, the bottom of the sieve box 3 is arranged on the base 5 through an elastic body, the top of the sieve box 3 is provided with a feed port 1, and the tops of both sides of the sieve box 3 An exhaust pipe 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com