Fuel cell system and method

A fuel cell system, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, transportation fuel cell technology, etc., can solve the problem of catalyst activity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

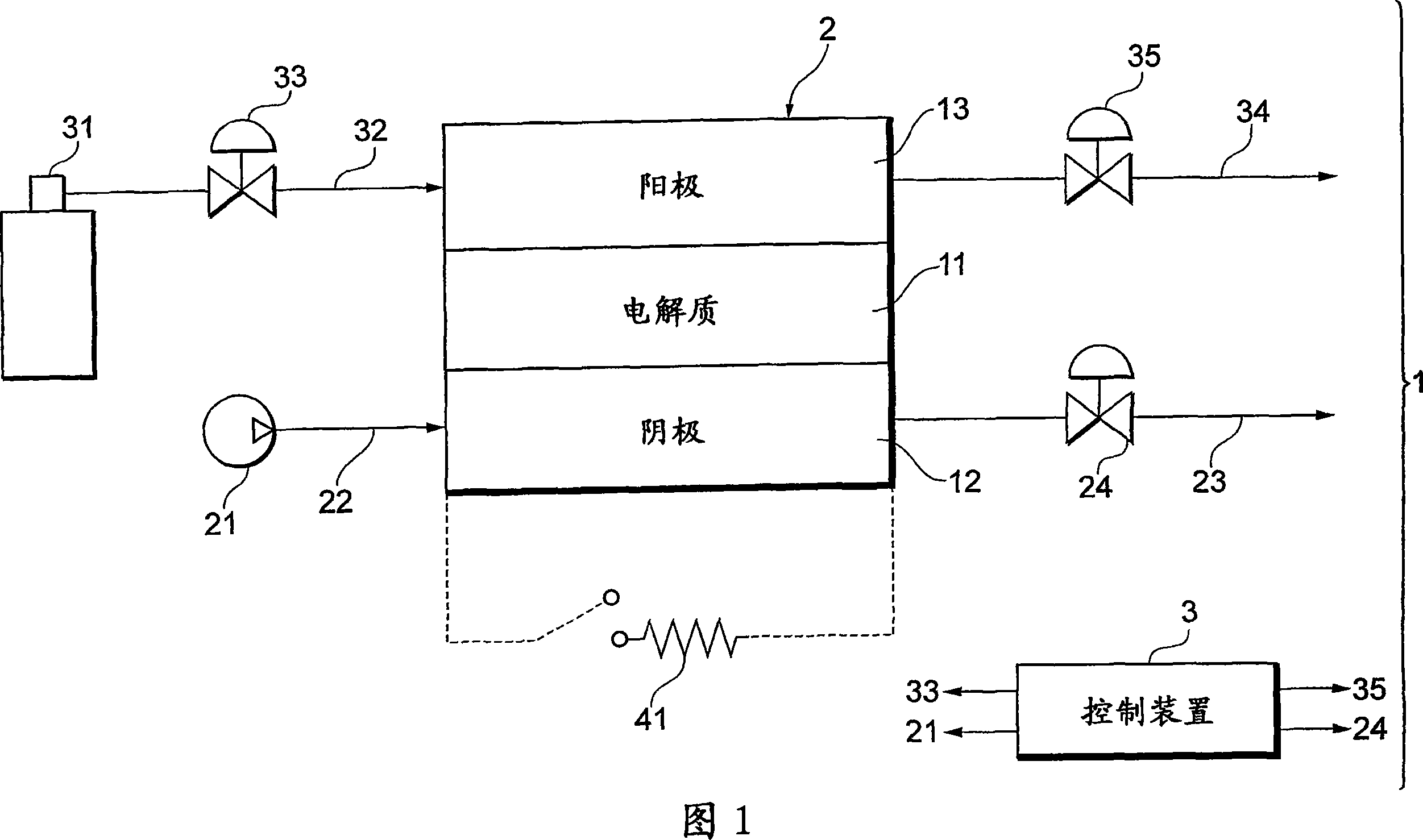

[0050] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0051] As shown in FIG. 1 , for example, a fuel cell system 1 mounted on a fuel cell vehicle includes a solid polymer electrolyte type fuel cell 2 suitable for vehicle use and a control device 3 that controls the entire system in an integrated manner. The fuel cell 2 has a stack structure in which a plurality of single-cell cells are stacked, receives supply of oxygen (air) as an oxidizing gas and hydrogen as a fuel gas, and generates electric power. In addition, when the fuel cell 2 is a stationary type, it is preferably a solid polymer electrolyte type or a phosphoric acid type. Even a stationary fuel cell system has the same fuel cell 2 and the same control device 3 .

[0052] A single cell of the fuel cell 2 is configured by arranging a cathode 12 (air electrode) and an anode 13 (fuel electrode) on both sides of an electrolyte membrane 11 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com