Liquid crystal display panel and method of manufacturing the same

A liquid crystal display panel, liquid crystal material technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven gap, light leakage, contrast reduction, etc., to increase the variation margin, no light leakage, high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

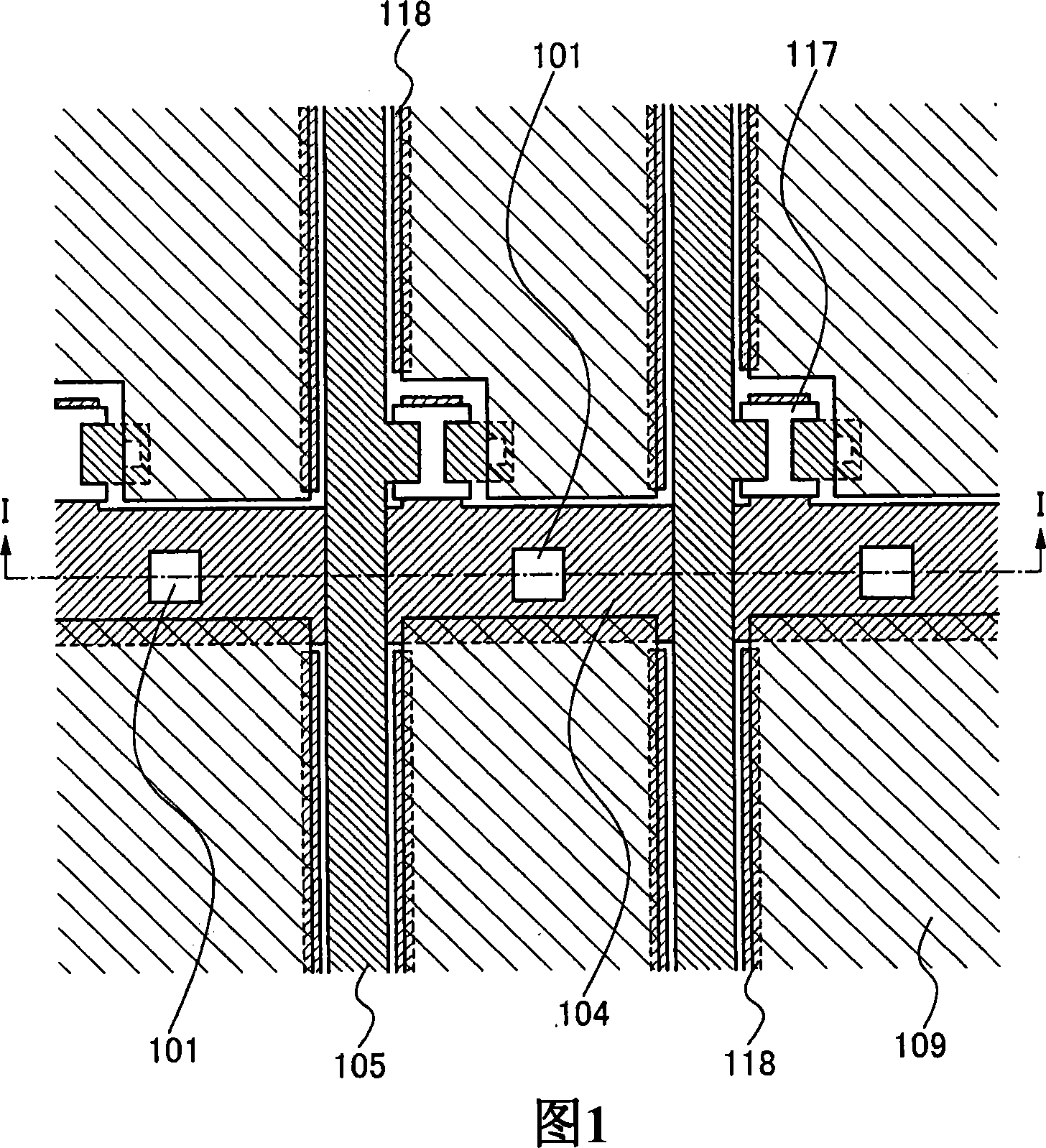

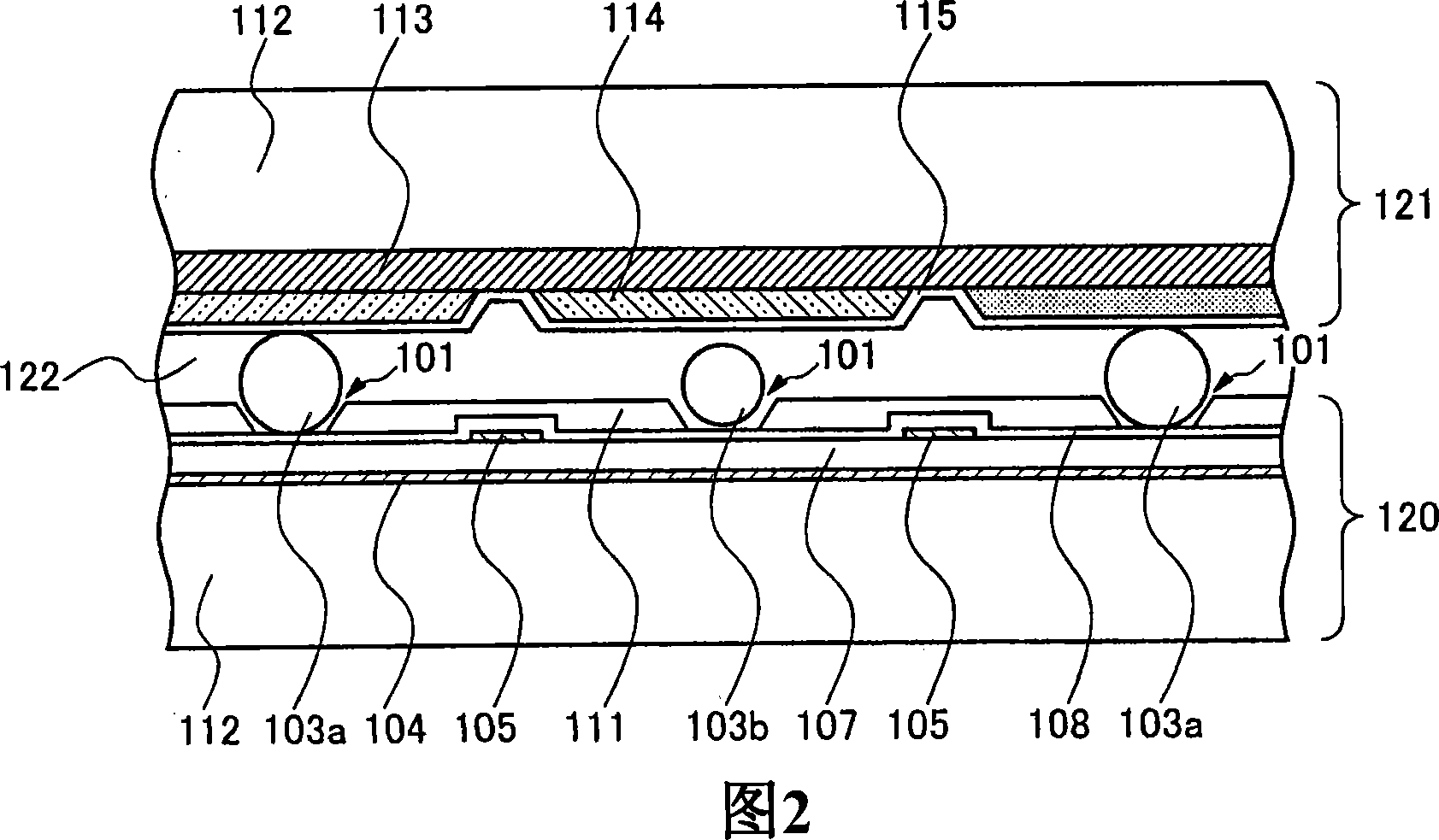

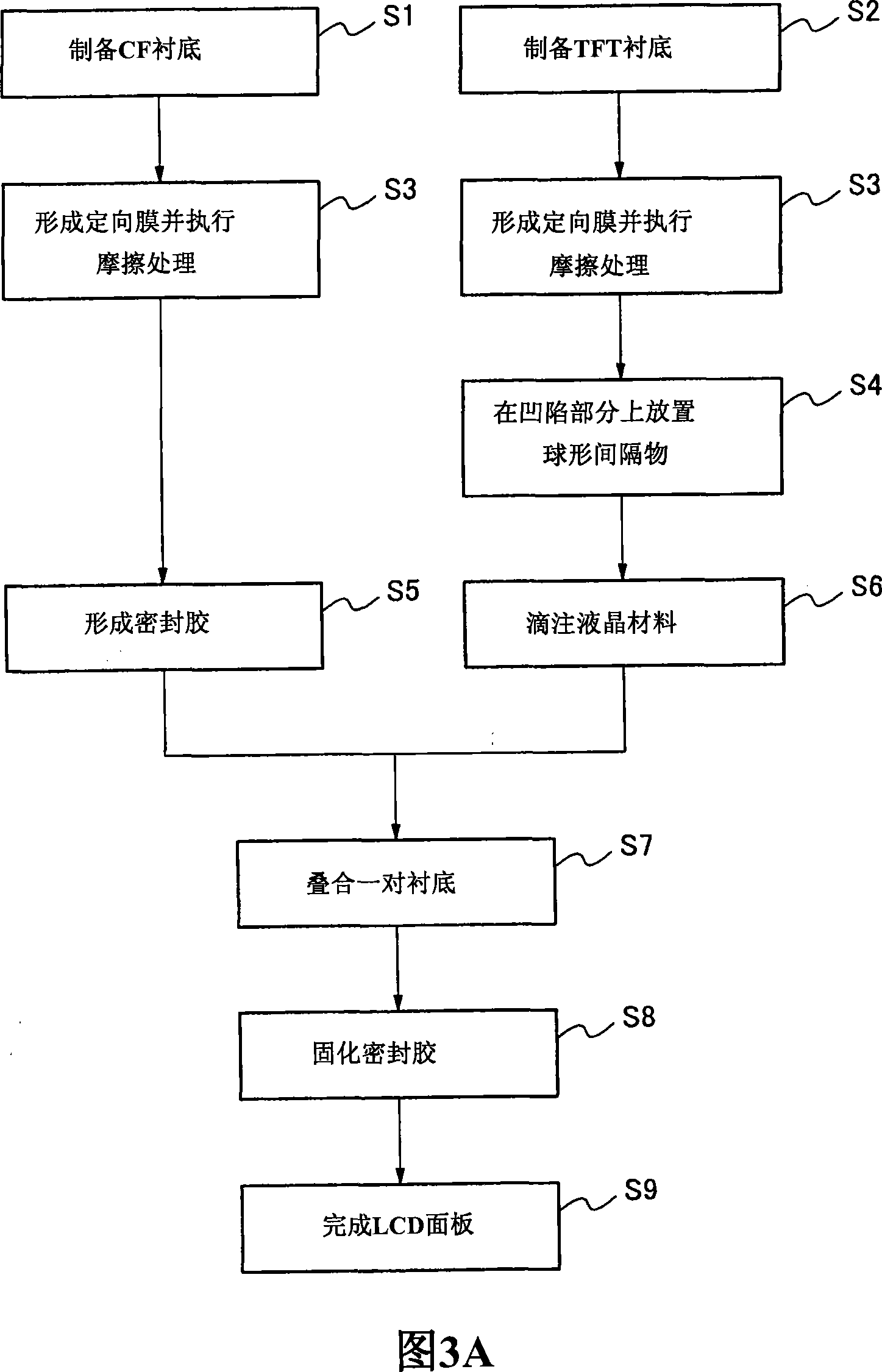

[0054] First, an LCD panel and a method of manufacturing the LCD panel according to a first exemplary embodiment of the present invention will be described with reference to FIGS. 1, 2, 3A, and 3B.

[0055] The LCD device device of the present embodiment includes an LCD panel, a backlight unit that illuminates the LCD panel, and the like. As shown in Figures 1 and 2, an LCD panel mainly includes an active matrix substrate, an opposite substrate facing the active matrix substrate, an approximately spherical The spherical spacer, and the liquid crystal material 122 sandwiched in the cell gap defined by the spherical spacer. On an active matrix substrate, switching elements such as TFTs are formed in a matrix. In this embodiment, an example of an active matrix substrate is explained using the TFT substrate 120 . An example of a counter substrate is explained using a color filter (CF) substrate 121 . An example of an approximately spherical spherical spacer is explained using t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com