Accumulator current sensor for automobile

一种电流传感器、蓄电池的技术,应用在只测电流、测量电流/电压、仪器等方向,能够解决不能完全避免机械应力、成本增加等问题,达到小热耦合、简单安装、避免机械应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

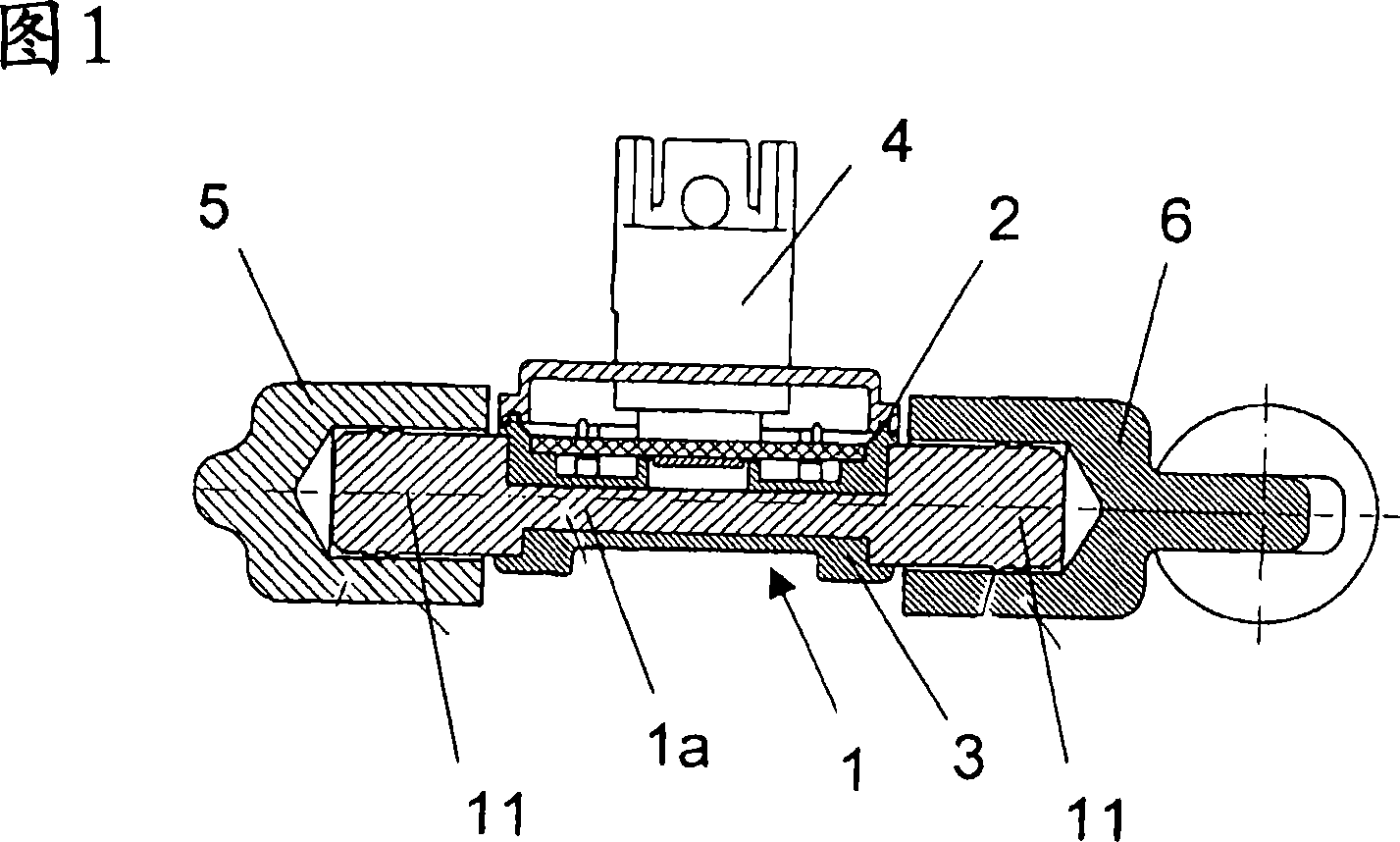

[0019] FIG. 1 shows a battery current sensor designed according to the invention in a sectional view. The battery current sensor has a measuring sensor 1 with a measuring resistor 1 a formed by a metal strip, which has a plastic encapsulation 3 in its central region, which forms part of the housing 2 . The housing 2 has a housing cover 9 as a further housing part, which has a plastic encapsulation 3 , preferably connected by laser welding, and which has a molded plug cage as part of the plug connector 4 .

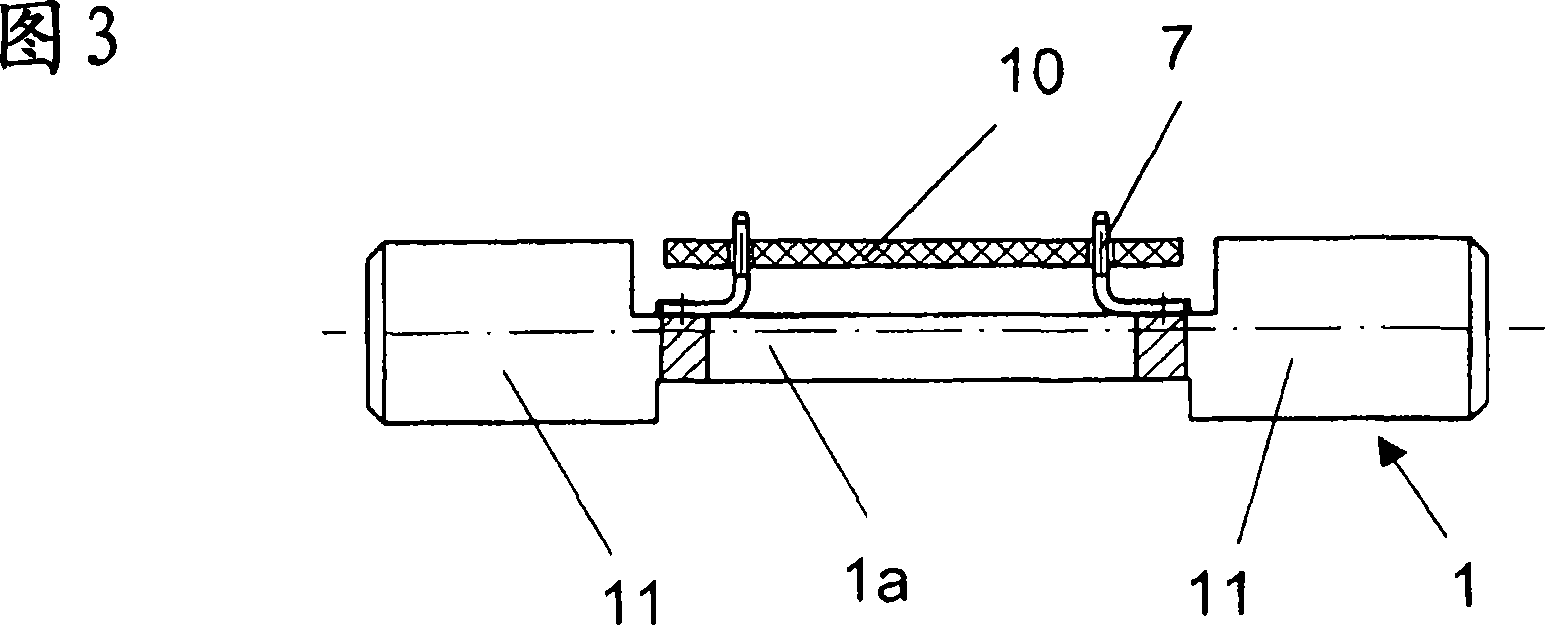

[0020] Measuring resistor 1 a has a simple cylindrical shaped part 11 on its end section, and connecting elements 5 , 6 are arranged rotatably about their central axis. After the relative position of the connecting elements 5 , 6 is fixed relative to the measuring sensor, their position is locked by co-pressing of the connecting points.

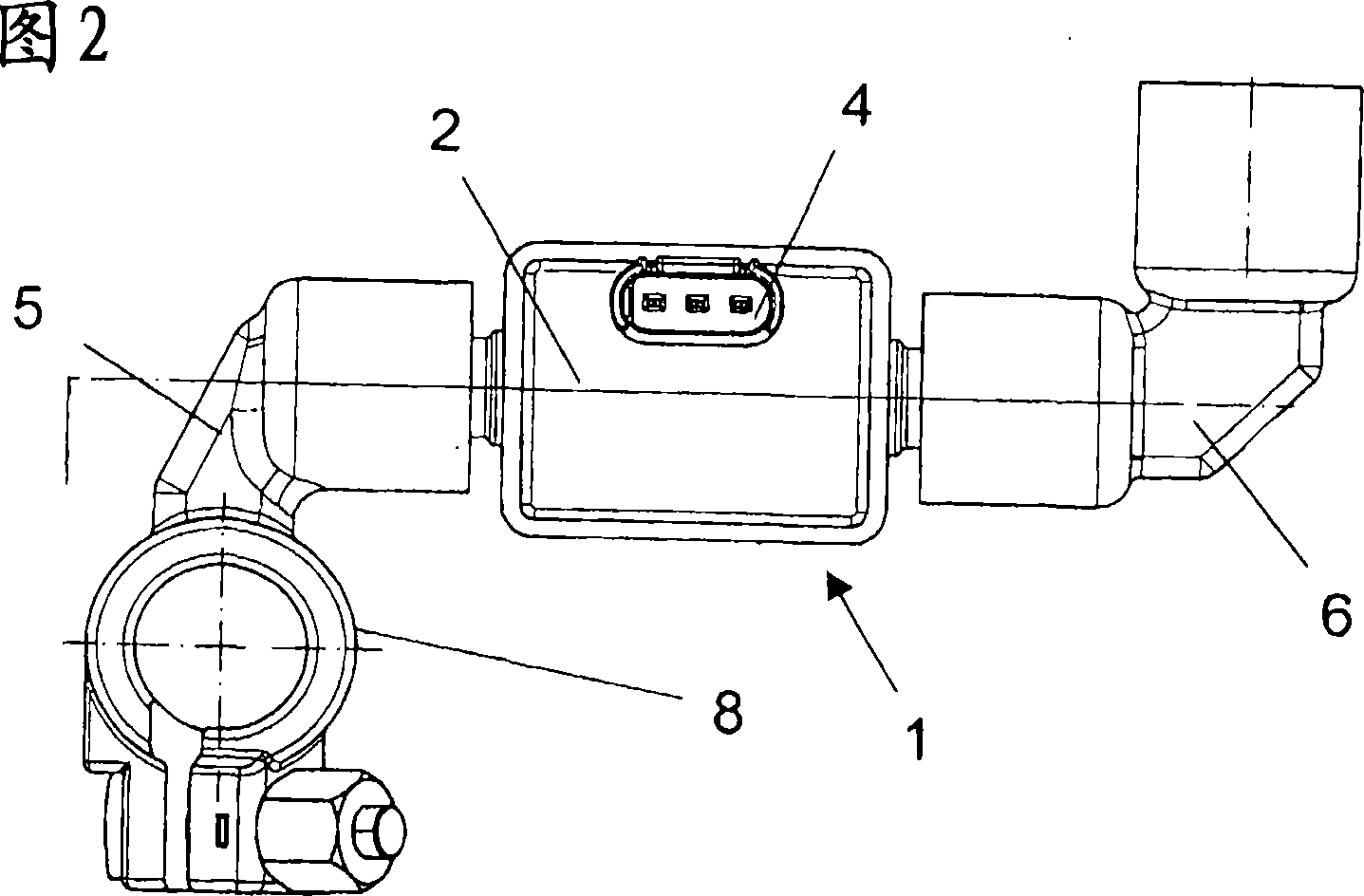

[0021] As shown in FIG. 2 , the first electrical connection element 5 is designed as a battery pole terminal 8 with a ring-shaped termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com