Small size self-walking type vibration compaction roller

A vibratory compaction, self-propelled technology, applied in the protection of roads and soils, road repair, etc., can solve the problems of low compaction efficiency, high cost, high noise, etc., to achieve stable walking speed, high compaction efficiency, structural high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

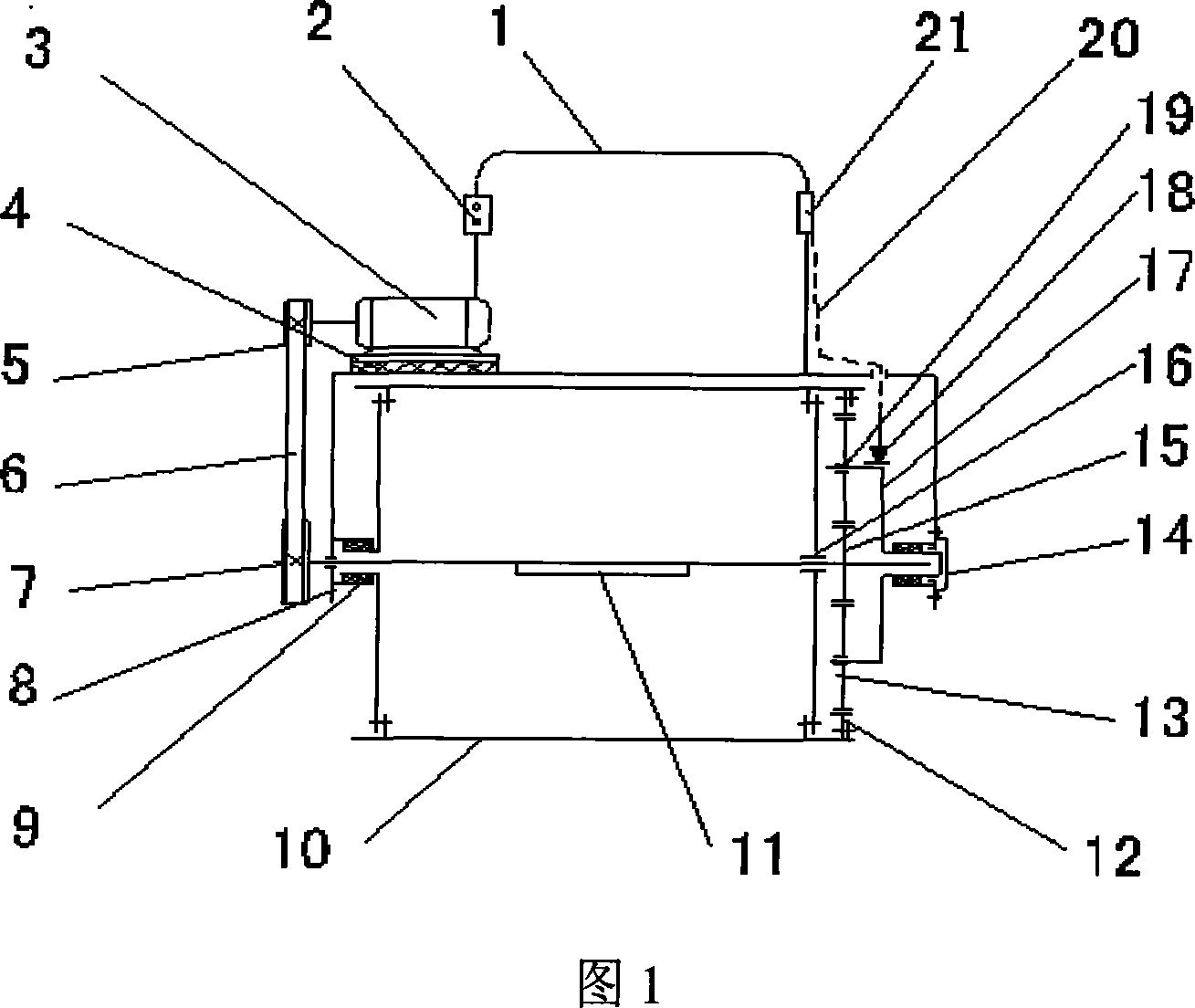

[0024] Embodiments of the present invention will be described below in conjunction with accompanying drawing 1 .

[0025] During specific construction, first transfer the compacting roller to the work site, the operator holds the handrail 1 with both hands, and then turns on the power switch 2, at this time the power on the motor 2 is transmitted through the belt transmission mechanism (5, 6, 7) To the eccentric shaft 11, the exciting force generated by the rotation of the eccentric shaft 11 is transmitted to the roller 10 through the slewing bearings 16 at both ends of the eccentric shaft 11 and the roller 10, so as to be loaded on the compacted medium. Simultaneously by manipulating the brake handle 21 to make the brake 18 brake the tie rod 17, then the intermediate gear 13 is equivalent to an idler wheel at this time, so the power is provided by the main gear 15, the intermediate gear 13 and the ring gear fixedly connected on the eccentric shaft 11. 12 is transmitted to the...

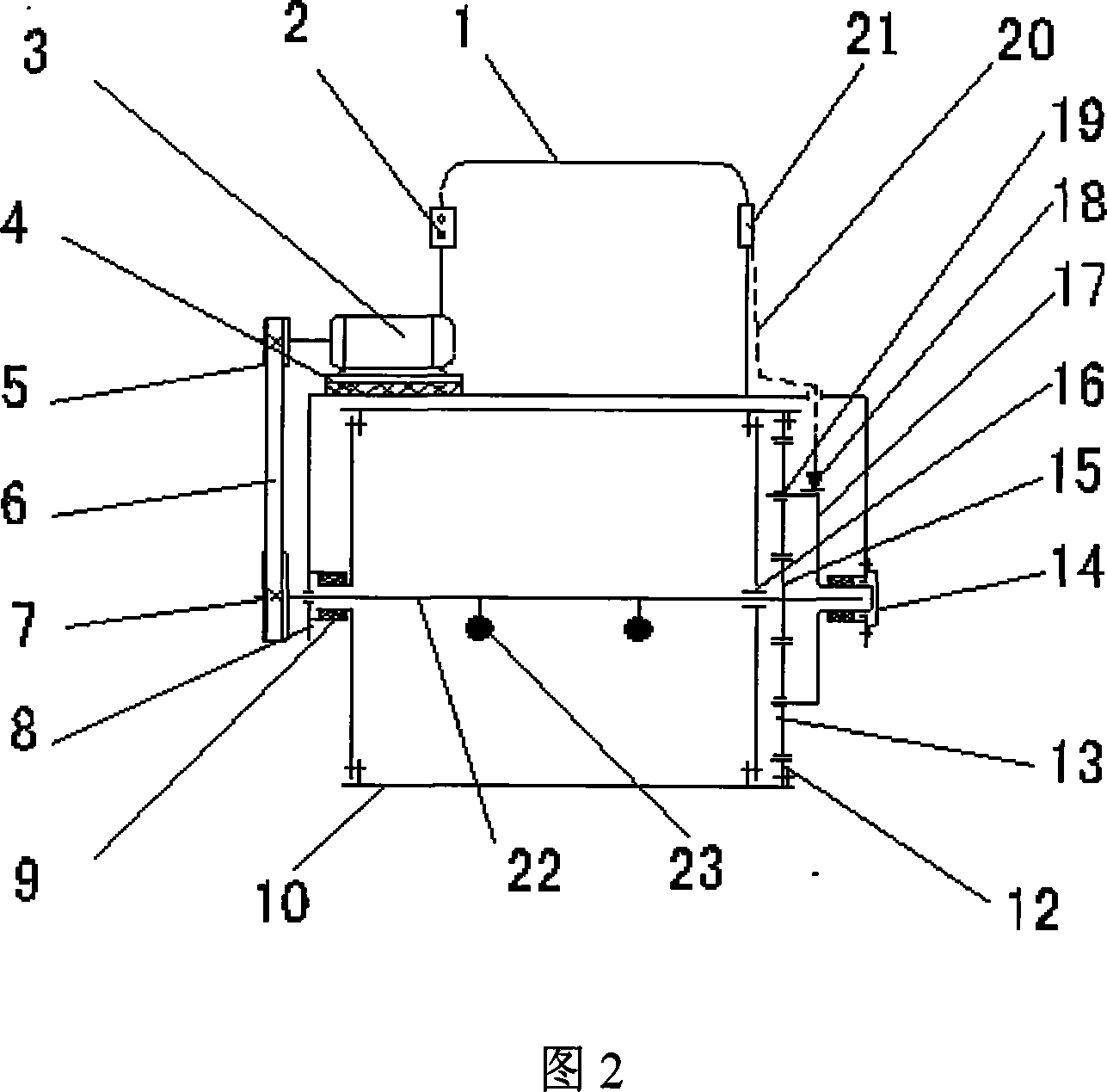

Embodiment 2

[0028] The working principle of embodiment 2 is basically the same as that of embodiment 1, except that the eccentric shaft 11 in embodiment 1 (see FIG. 1 ) is replaced by two eccentric blocks 23 (see FIG. 2 ) consolidated on a transmission shaft 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com