Enclosed oil pump assembly for motorcycle

A closed, motorcycle technology, applied in engine components, liquid fuel feeders, machines/engines, etc., can solve problems such as the size limitation of the built-in oil pump, inconvenient installation, etc., to achieve constant temperature, convenient installation, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

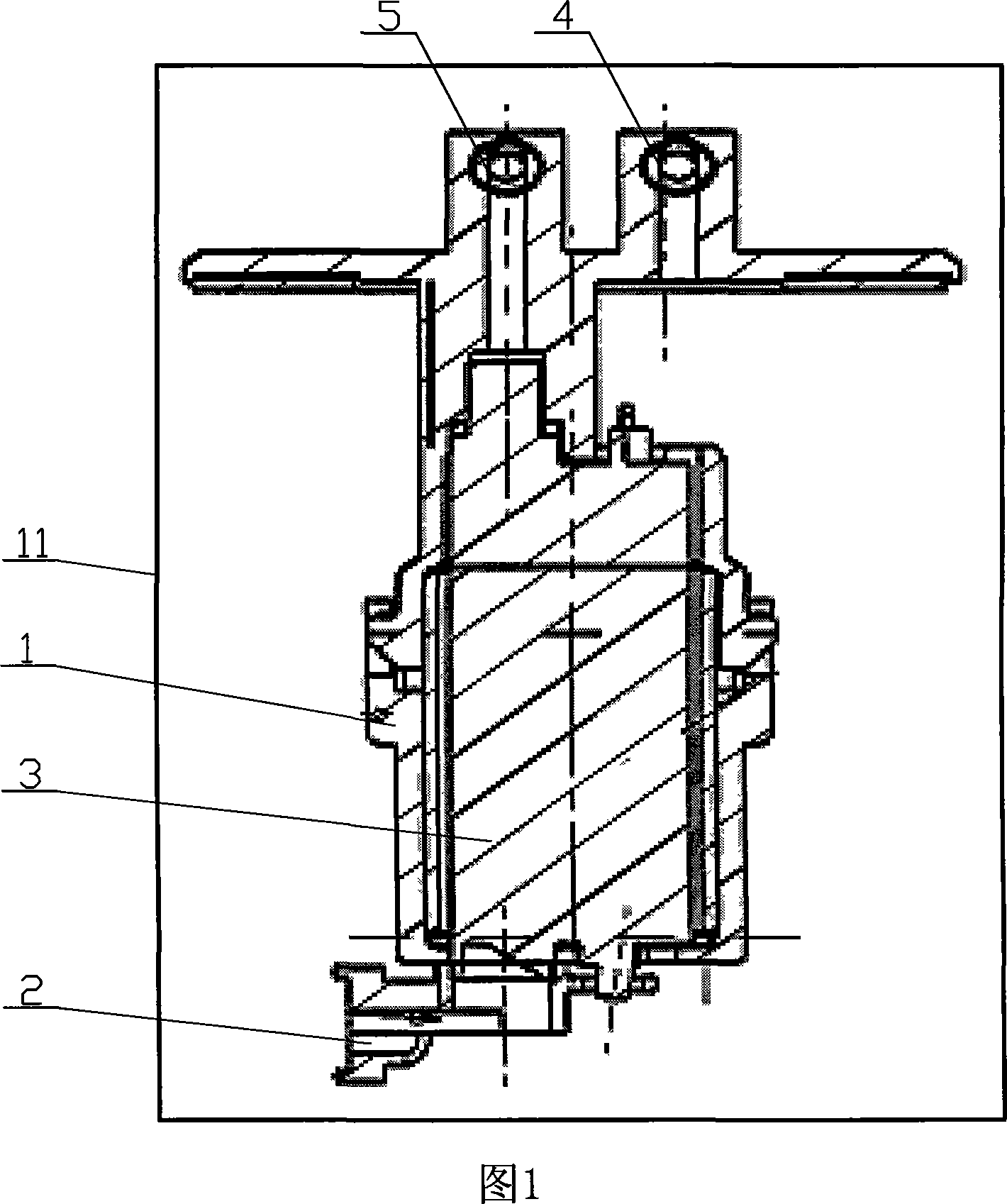

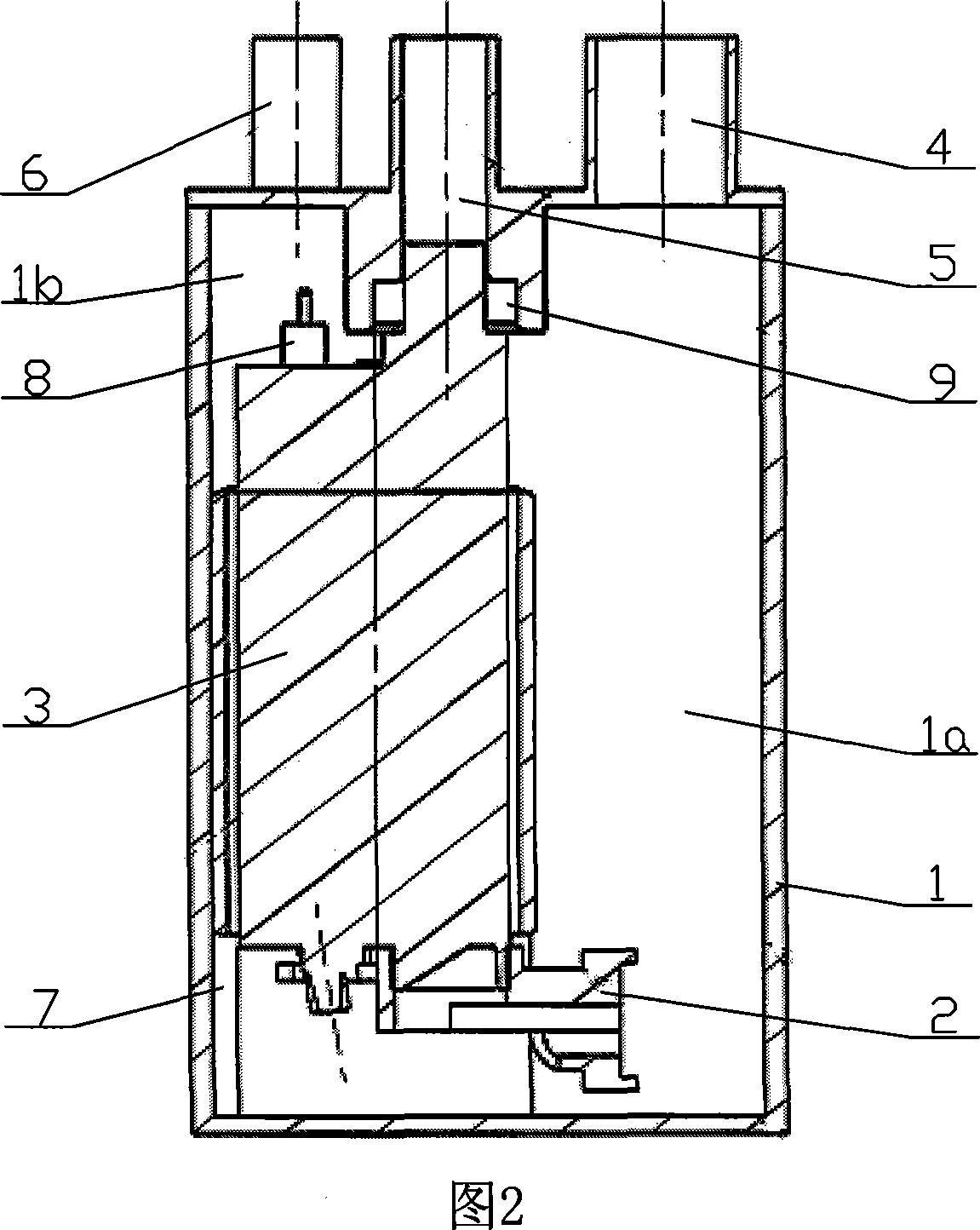

[0018] Please refer to Fig. 2, the present invention 14 is mainly made up of housing 1, filter screen 2, oil pump 3, oil inlet pipe 4, oil outlet pipe 5, exhaust pipe 6, base 7, wherein filter screen 2 is connected with the inlet of oil pump 3 bottom , the oil pump 3 and the filter screen 2 are put into the casing 1, and its volume is smaller than the inner cavity volume of the casing 1, and the cavity volume 1a+1b formed between the oil pump 3 and the inner wall of the casing 1 is not Less than 1 / 4 of the volume of the oil pump 3, which is about 1 / 2 in this embodiment; an oil inlet pipe 4, an oil outlet pipe 5, an exhaust pipe 6, and a power supply connected to the inner cavity are arranged on the cover of the housing 1 Plug 16, the oil outlet nozzle of the oil pump 3 is inserted into the oil outlet pipe 5 of the housing 1, the power terminal 8 of the oil pump 3 is connected to the power plug 16 through a wire; the oil pump 3 is installed on the Inside the casing 1, the filte...

Embodiment 2

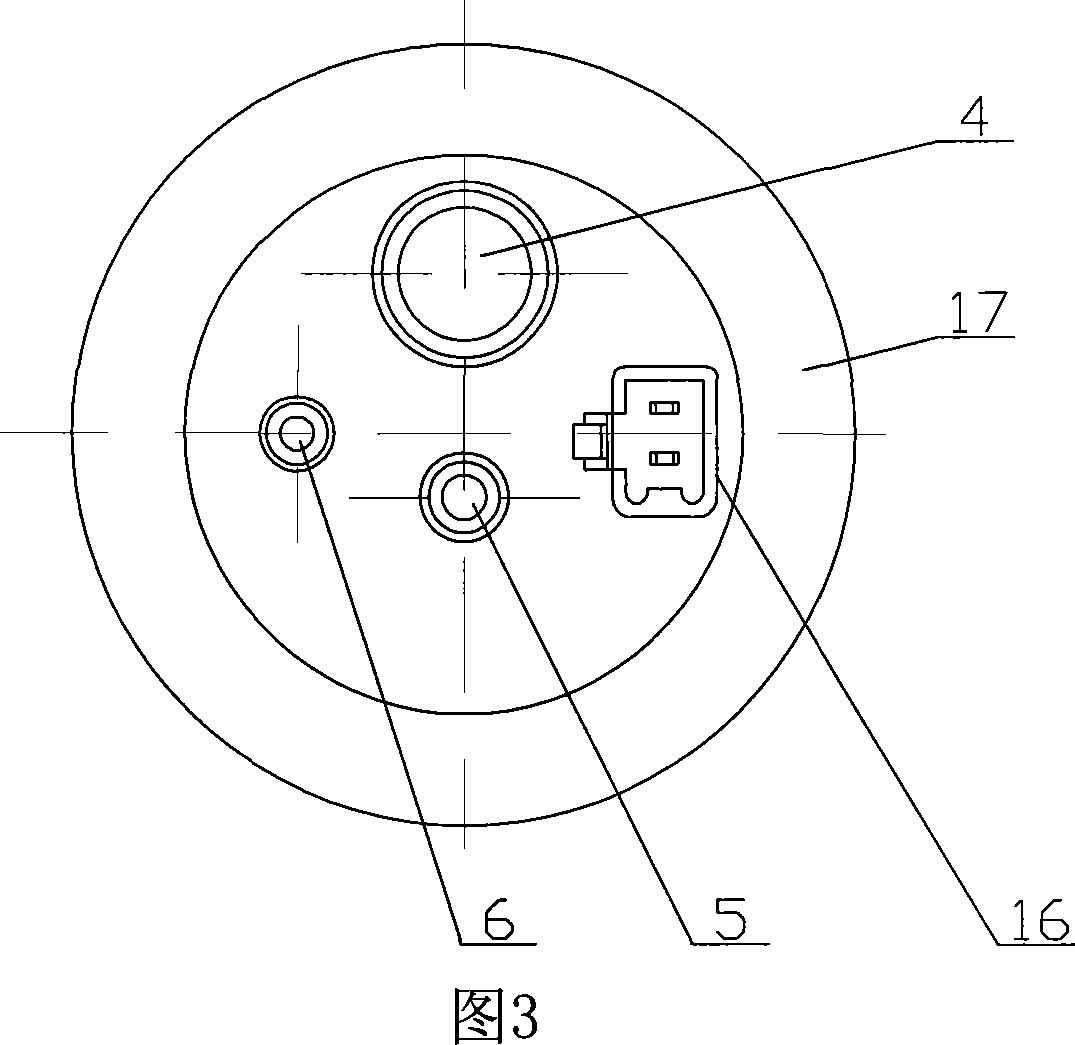

[0021] Please refer to Fig. 3, the present invention 14 is mainly composed of housing 1, filter screen 2, oil pump 3, oil inlet pipe 4, oil outlet pipe 5, exhaust pipe 6, base 7, sealing ring 9, O-shaped sealing ring 10, power plug 16 , Compression cover 17, this embodiment is basically the same as the main content of the composition and connection relationship of the first embodiment, the difference is: the shell 1 is composed of a shell cover and a shell body, and the shell cover is O-shaped The sealing ring 10 is covered on the opening end of the shell body, and fits tightly; there is a compression cover 17 with a central opening on the shell cover, the compression cover 17 is threaded with the shell body, and the oil inlet pipe 4, The oil outlet pipe 5, the exhaust pipe 6, and the power plug 16 protrude from the central hole of the pressing cover 17. In addition, the volume 1a+1b of the cavity formed between the oil pump 3 and the inner wall of the housing 1 is not less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com