High light transmittance ratio touch screen

A high light transmittance, touch screen technology, applied in the touch screen field, can solve the problems of the stability of the overall light transmittance without the wear resistance of the outer layer, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

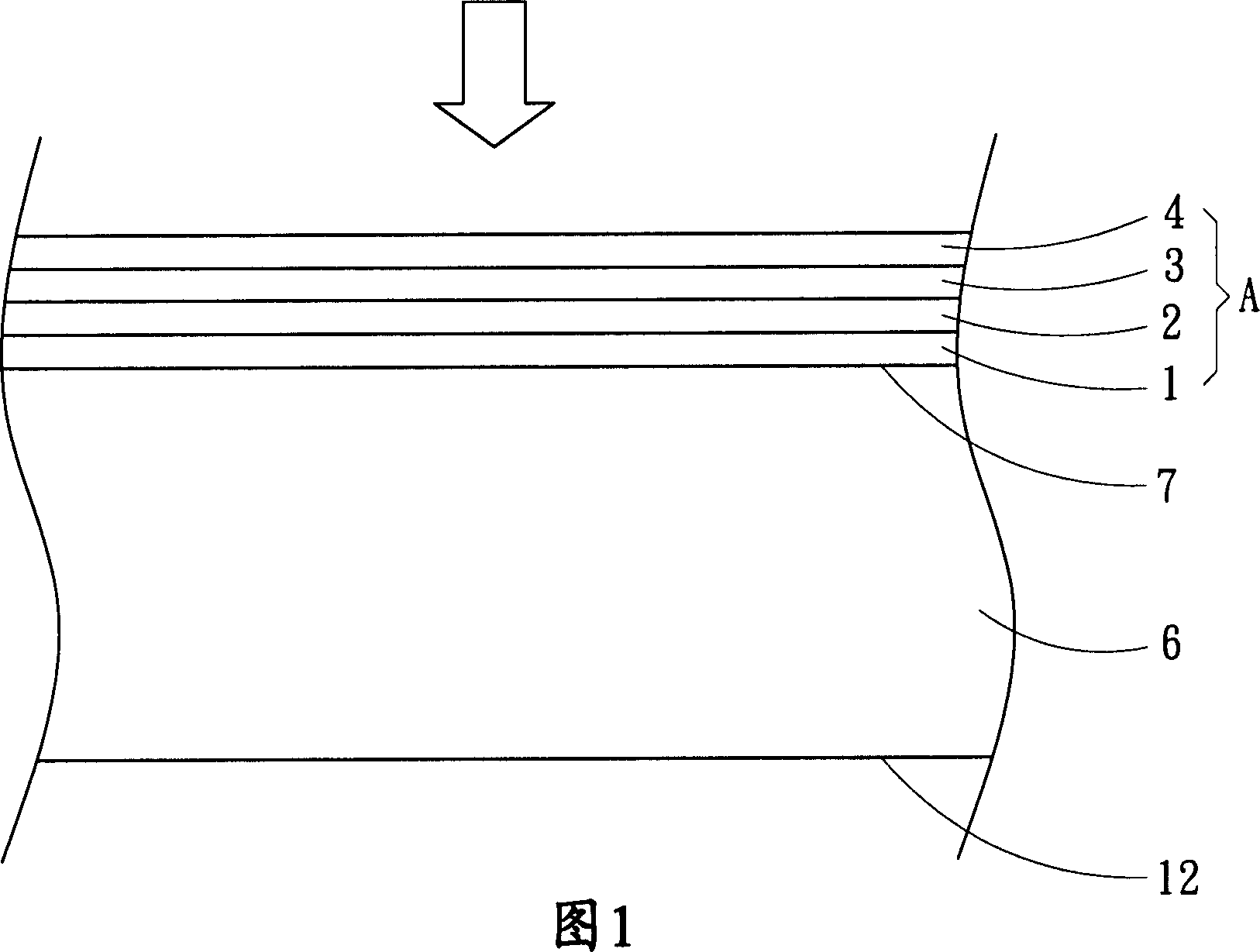

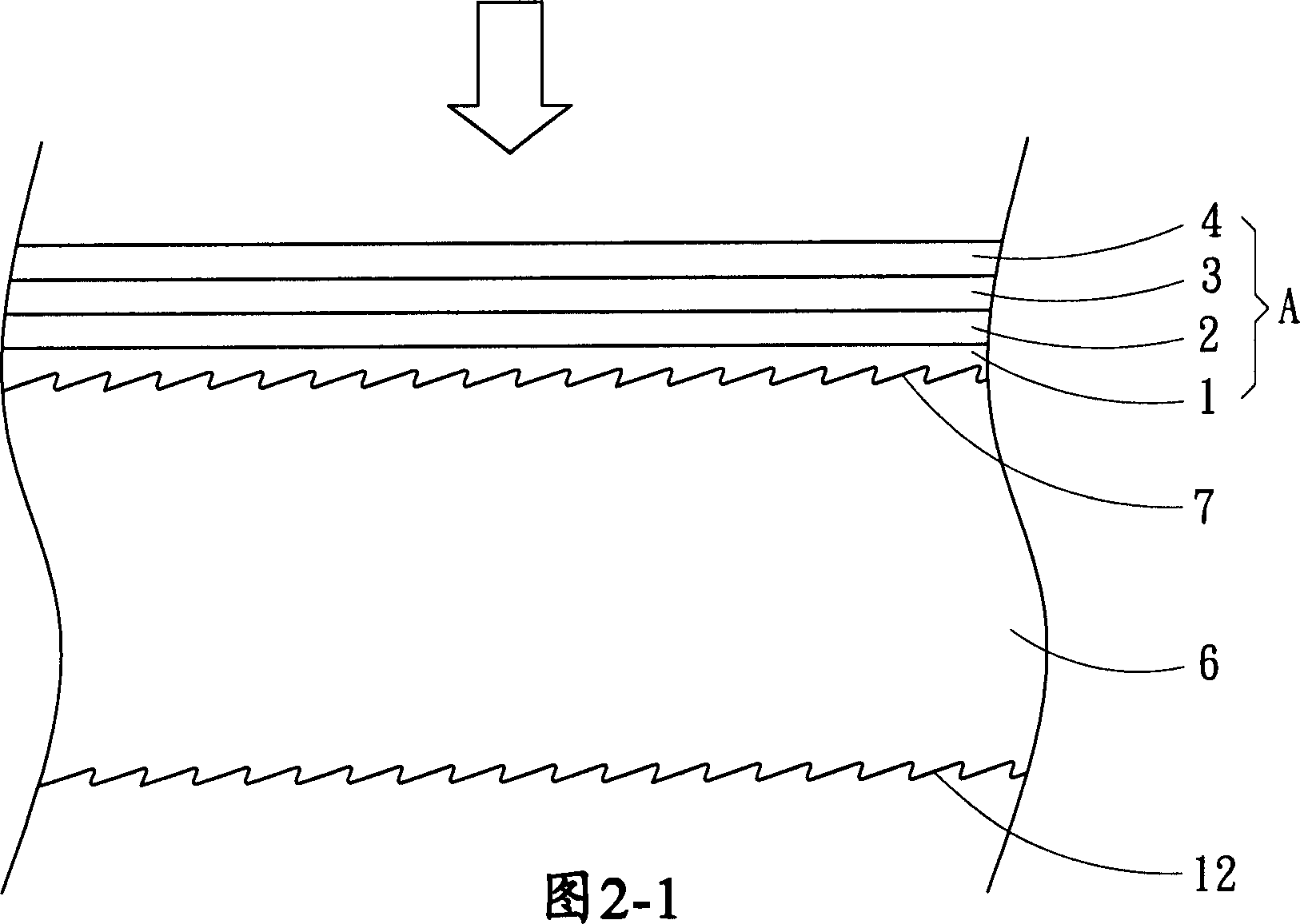

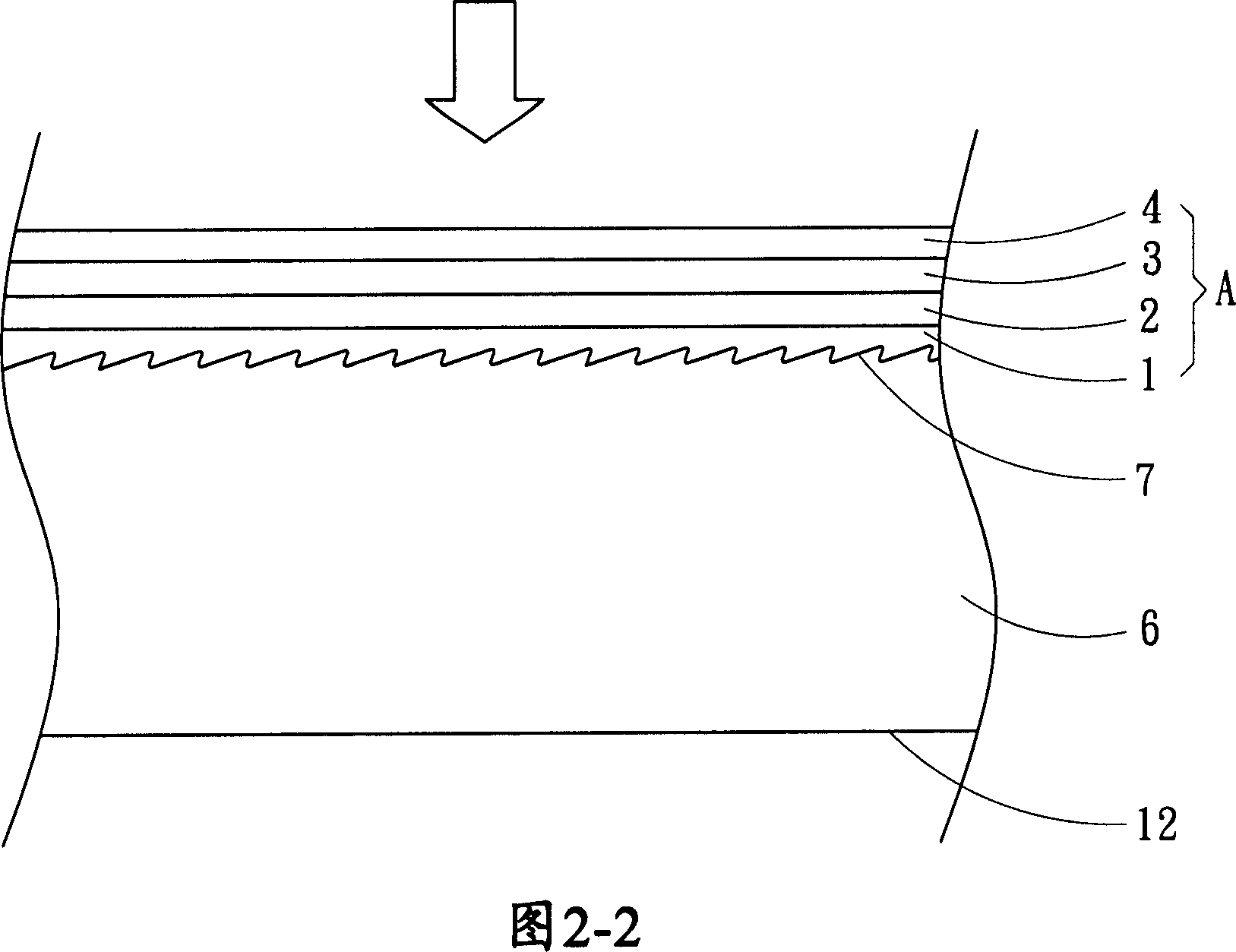

[0020] Relevant preferred embodiment of the present invention and technical content, now in conjunction with accompanying drawing are described as follows:

[0021] First, please refer to FIG. 1 , in the first embodiment, the high transmittance touch screen of the present invention has a substrate 6 and a first anti-reflection coating layer structure A. As shown in FIG. Wherein, the substrate 6 has a front surface 7 and a reverse surface 12 relative to the front surface 7. It is defined here that the front surface 7 refers to the side adjacent to the user, and the reverse surface 12 refers to the side adjacent to the backlight source. The substrate 6 can be It is made of glass, plastic or other transparent materials; the first anti-reflection coating layer structure A is a four-layer structure, including a first layer 1, a second layer 2, a third layer 3 and a first layer Four layers 4, and the first layer 1, the second layer 2, the third layer 3 and the fourth layer 4 are seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com