Regeneration and brake management system

A regenerative power system, regenerative braking technology, applied in electric braking systems, brake control systems, brakes, etc., can solve problems such as reducing vehicle stability, brake wear, uneven tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

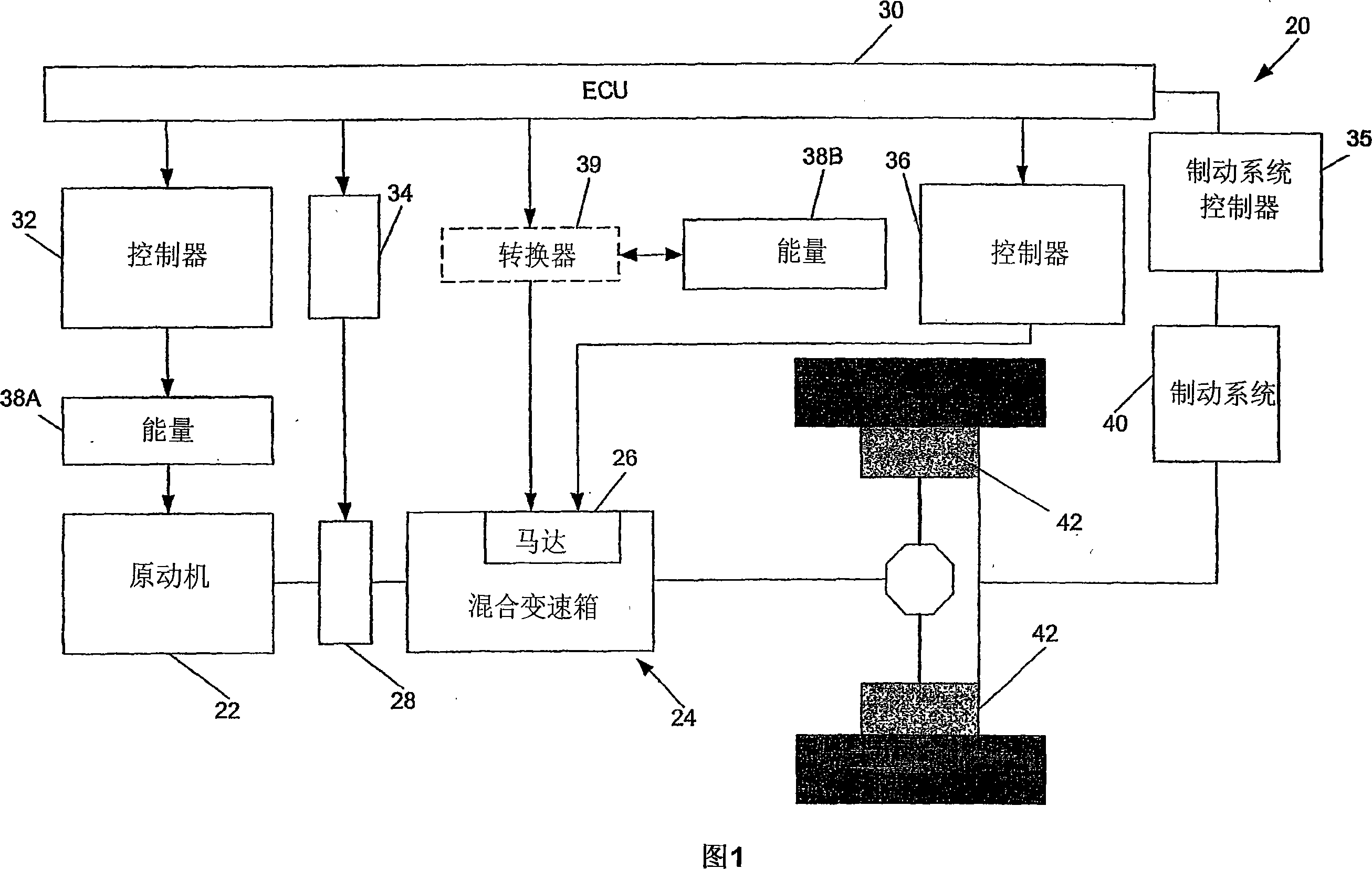

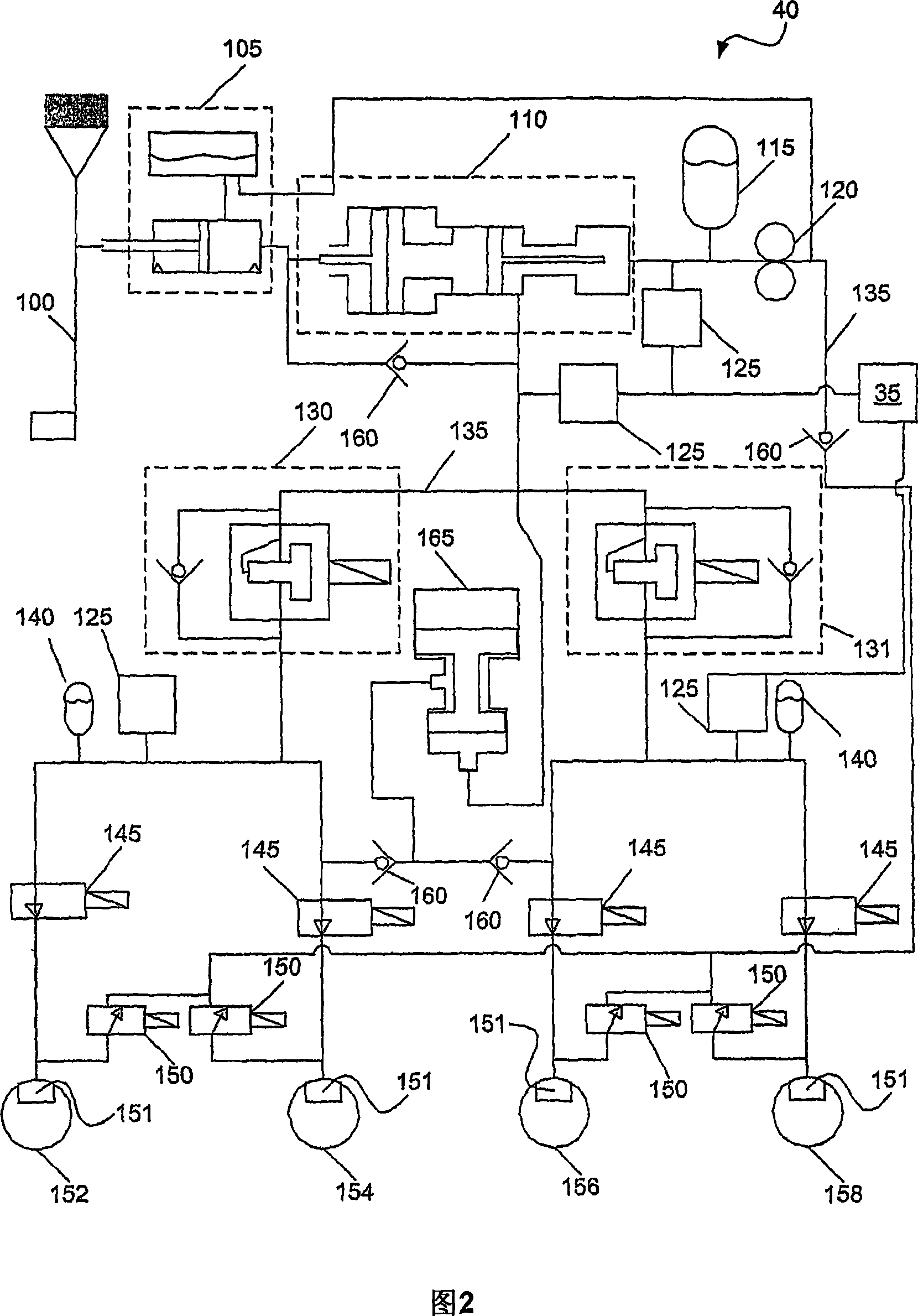

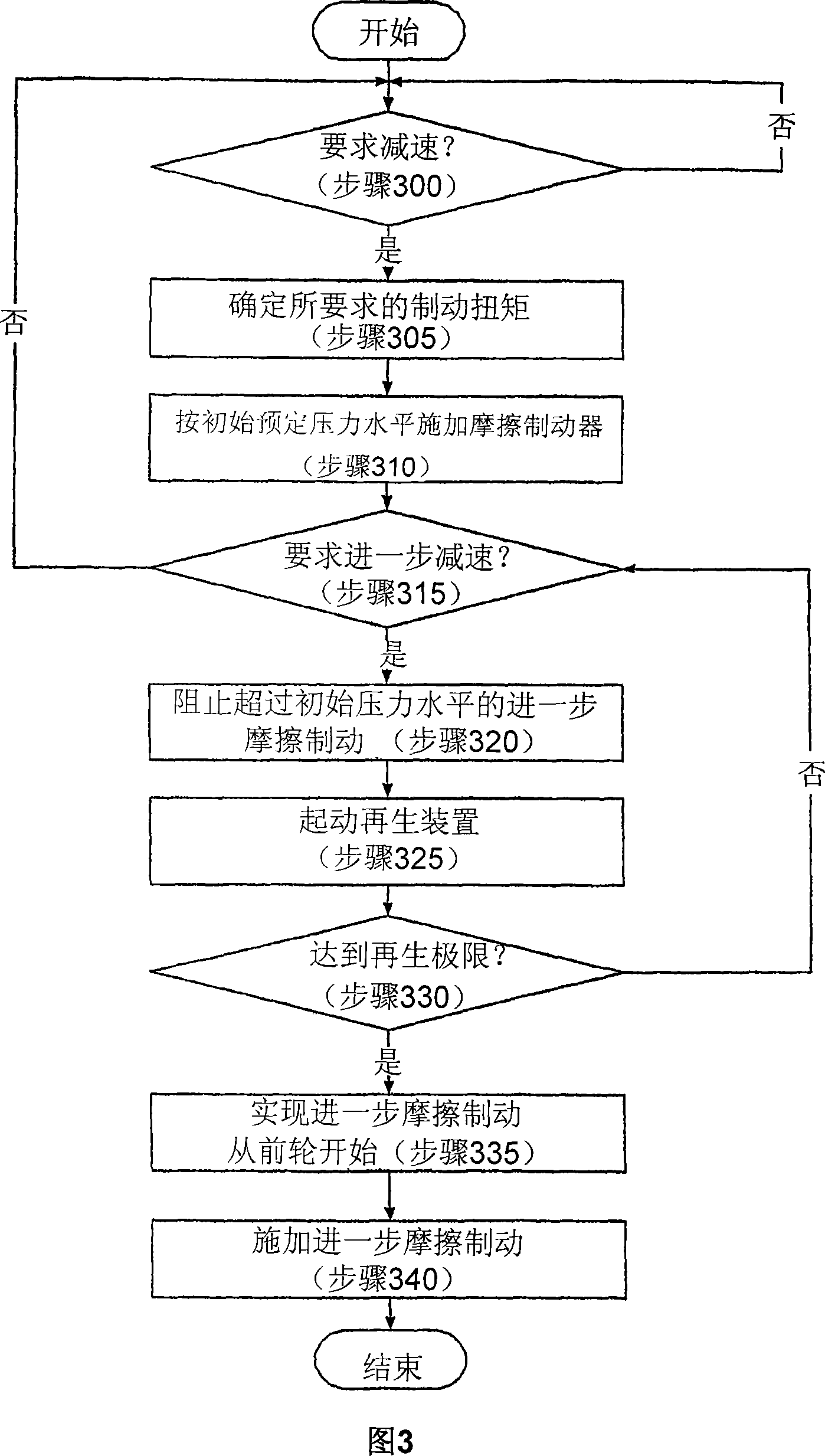

[0017] The present systems and methods provide an integral, anti-skid, hydraulic brake pressure booster and regeneration control system. Specifically, the present systems and methods are designed to maximize the energy accumulated through regenerative braking by at least partially disabling the friction brakes when sufficient deceleration can be obtained through regenerative braking. Energy regeneration is thus maximized while giving the vehicle the required amount of deceleration. In addition, the vehicle's anti-skid function is enhanced by a controller that manages and distributes the maximum allowable kinetic energy available to the battery and distributes excess energy to the appropriate friction brakes. By predicting and monitoring the torque of the regenerative device in terms of current, combined with the detection of driver pedal input intention and wheel speed information, regeneration is maximized without causing vehicle driving problems, such as wheel slippage, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com