Thermoplastic material container

A thermoplastic, container technology, applied in the direction of containers, bottles, rigid containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, particular reference is made by way of example to a generally cylindrical container of revolution, such as a bottle, however, it should be understood that the application of the present invention is not limited to this type of container and may be applied to Containers having other shapes, especially polygonal, especially square or rectangular.

[0026] It should also be emphasized that the measures of the present invention apply only to containers intended to hold dead liquids (i.e. non-carbonate liquids), more specifically to contain dead water, in particular A bottle for drinking still water, though that's not all.

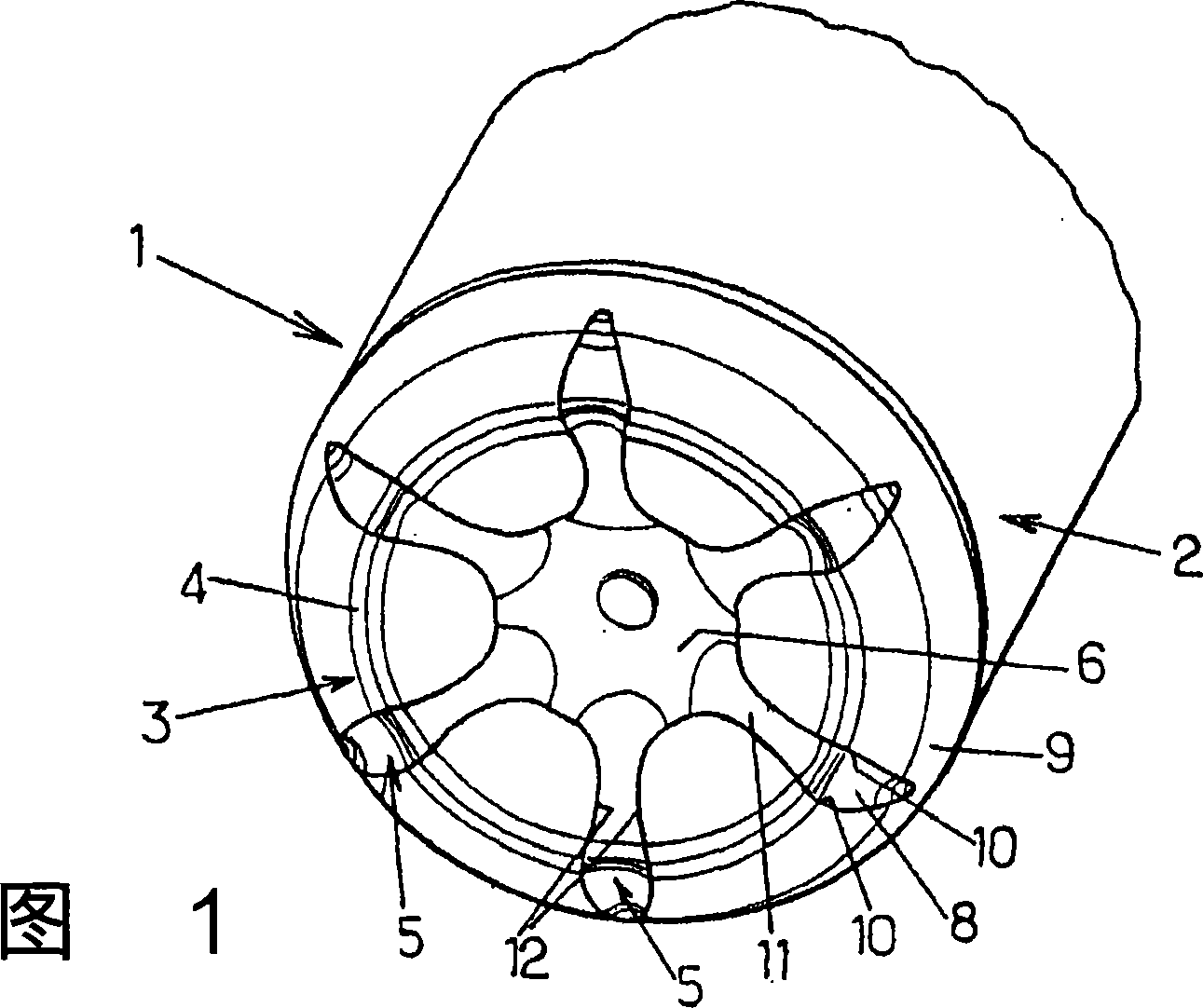

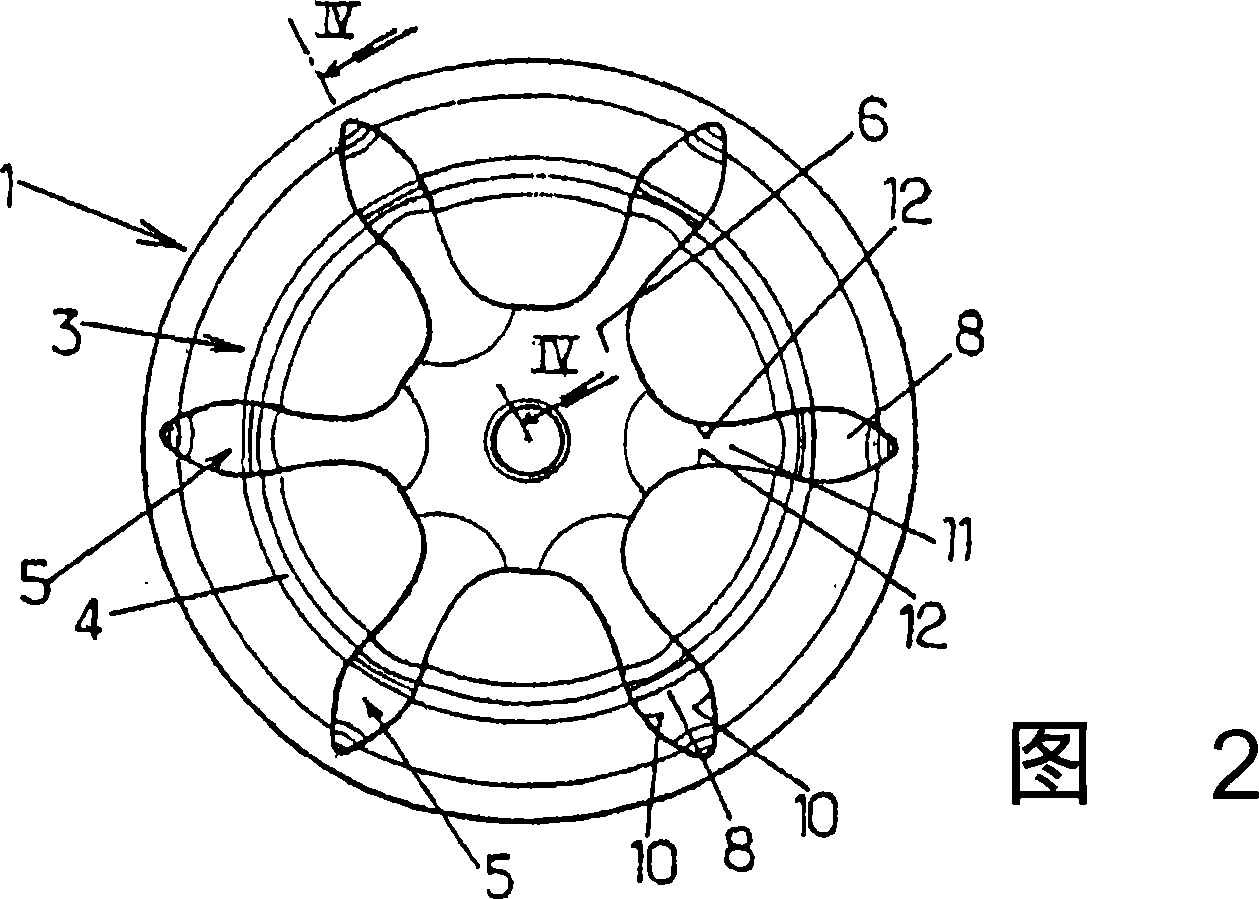

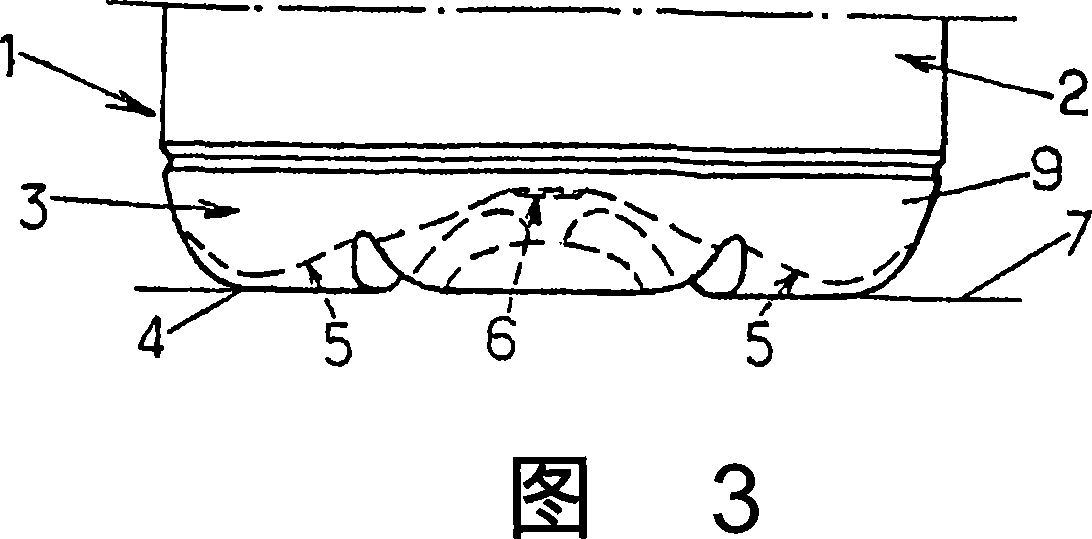

[0027] Figures 1 to 3 give representations of a portion of a container 1, in this example manufactured from a thermoplastic such as PET and blow molded by blow molding a preform preheated to the softening temperature of the thermoplastic. Bottles made by extrusion or stretch blow molding. The bottle comprises a body 2 (onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com