Circuit board and electric plating sludge resource recovery process

A technology of electroplating sludge and resource recovery, which is applied in the field of resource recovery technology, can solve problems such as environmental pollution, achieve a wide range of applications, and overcome the effects of limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

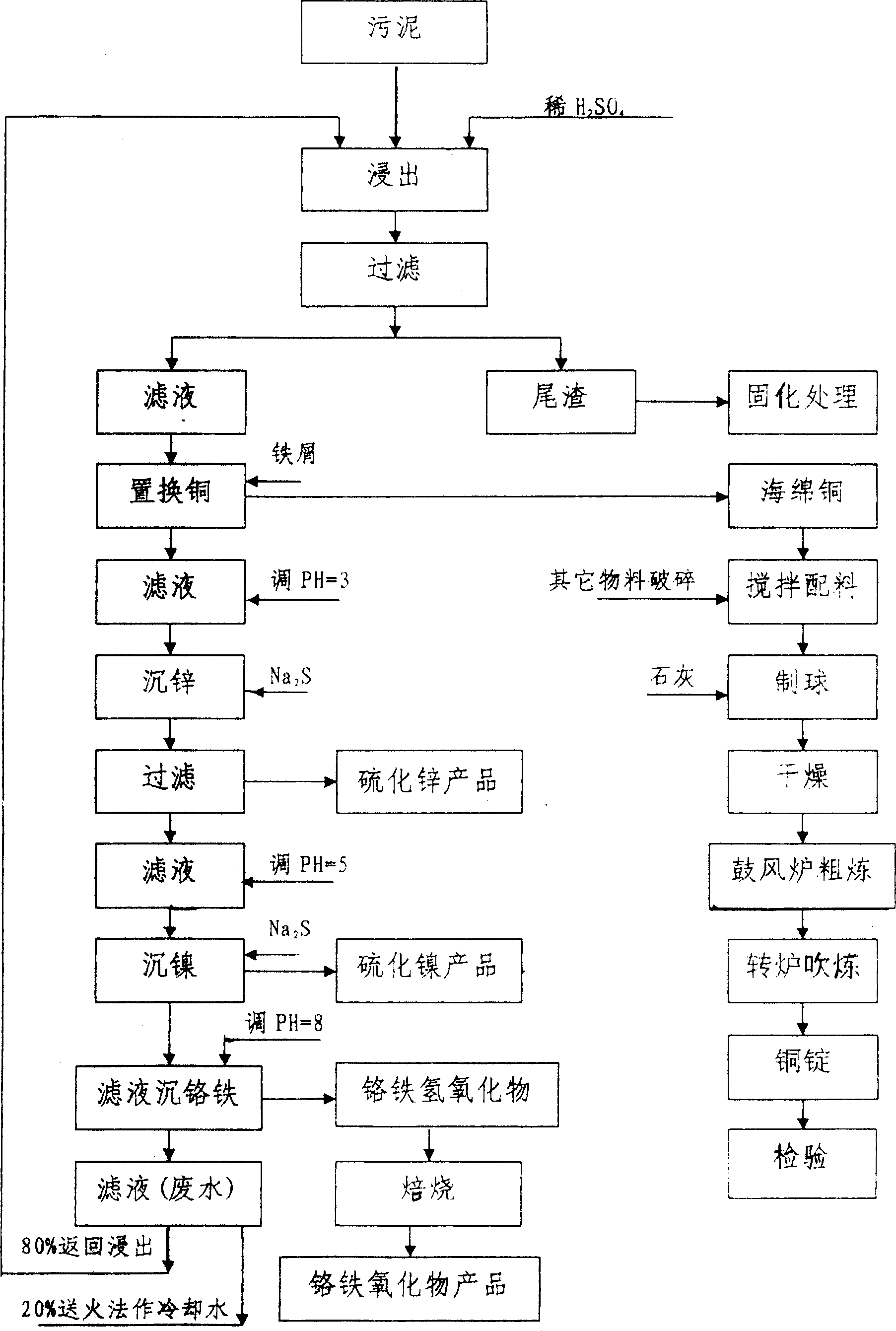

[0013] As shown in Figure 1, put the sludge into the leaching tank, add dilute sulfuric acid according to the ratio of solid-liquid ratio of 1:0.6, stir at room temperature for 40 minutes, control the pH value of the end-point leachate to 1.5-2, then filter, and The filtrate is pumped into the replacement tank, and the leach slag is treated separately; in the filtrate of the replacement tank, iron filings are added according to 1.4 times the copper content of the filtrate, stirred at room temperature for 30 minutes, then filtered, and the filtrate is pumped into the zinc extraction tank to obtain Sponge copper containing 70-90% copper, adding sponge copper into coke, lime and sand in proportion, mixing well and putting them into blast furnace for rough refining to produce crude copper ingots containing more than 95% copper; the filtrate in the zinc extraction tank Add NaOH to control the pH value of the filtrate to 1.5-3, according to the ratio of zinc to Na 2 Add 30% Na in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com